DRAWING DATE 5-20-19

Bethpage NY

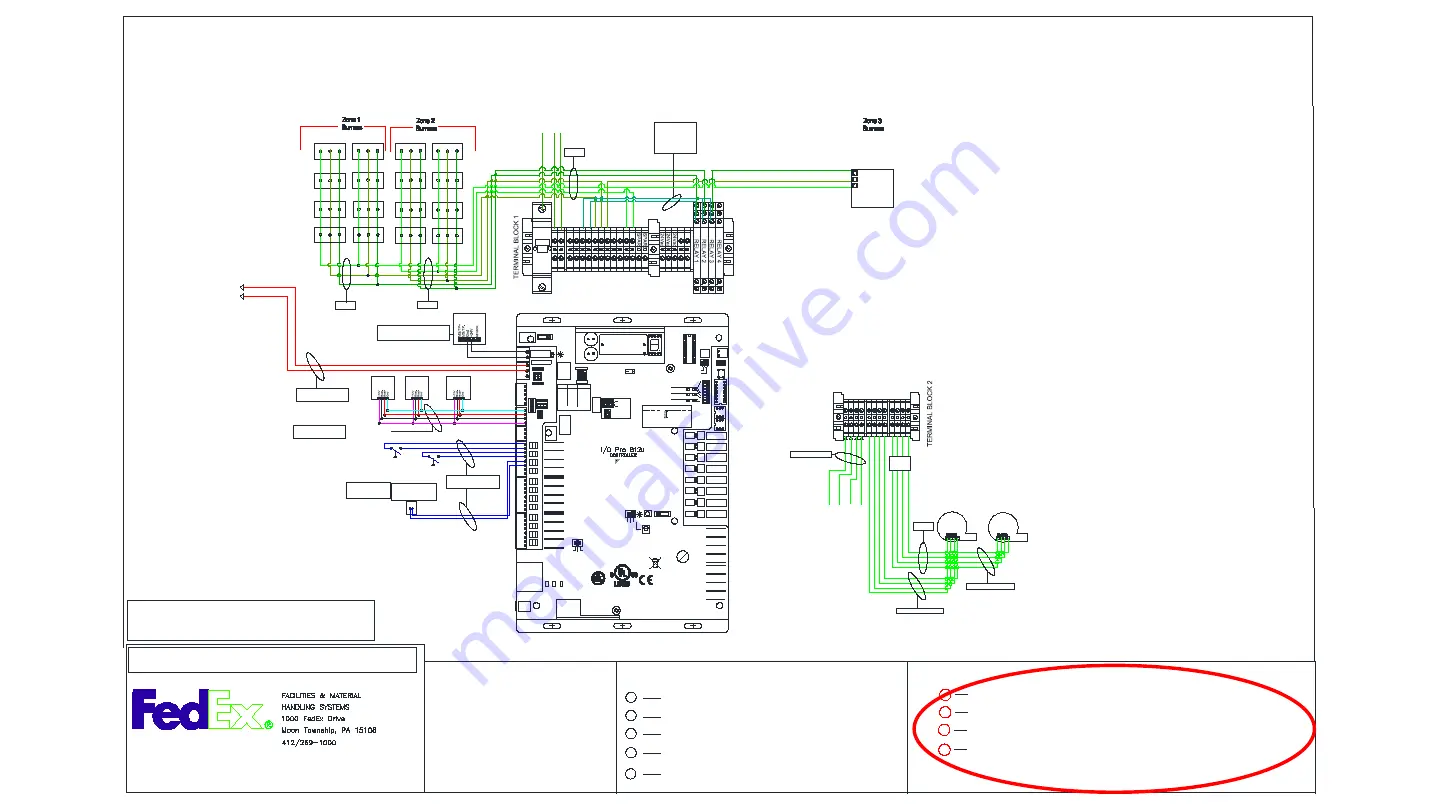

round

G

120V supply circuit

2 wire w/ground

120v - burner power from controller

2 wire w/ground

VPS, outdoor air sensor -

Indoor Sensor -

Communication RS485 -

OS - Outdoor Sensor

S - Indoor Sensor

EP- 203/303 - Vacuum Pump

A

B

C

460V - 3 phase supply circuit 3 wire w/ground, 5A

Power Wiring

Control Wiring

VFD - Variable Frequency Drive

VFD speed -

D

VPS - Vacuum Proving Switch

120v - VFD enable signal

2 wire

4

B1 - CRV Burners

3

2

1

CTH3 - COMPLETE Heater

Equipment List

shielded, 1 twisted pair, 22AWG, Beldon 3015A

shielded, 1 twisted pair, 18AWG, Beldon 8760

shielded, 2 twisted pair, 22AWG, Beldon 9681

shielded, 1 twisted pair, 18AWG, Beldon 8760

88F0

E143900

TYPE: 002003

Power

Off On

Power

Gnd

24Vac

Port 1

485

ARC-

Shield

Net -

Net +

156

Port 2a

Rnet

Gnd

Rnet +

Rnet -

+12V

Xnet +

Xnet -

Gnd

Xnet Expansion

Local

Rnet+

Gnd

Sense

+12V

Rnet-

Access

EIA-485

EIA-232

Thermistor/

dry-contact/

Mode Select

Universal Input

mA

RTD

Volts

10V Max, 20mA Max

Inputs: All

UI-4

UI-3

UI-2

UI-1

Gnd

+

Gnd

Gnd

+

+

Gnd

+

8

7

6

5

4

3

2

1

UI-8

Gnd

UI-6

UI-7

UI-5

Gnd

+

+

Gnd

+

Gnd

+

UI-12

UI-11

UI-10

UI-9

+

Gnd

+

Gnd

Gnd

+

Gnd

+

24 Vdc

24 Vdc

200mA maximum

Auto Off On

0-20mA

0-10Vdc

Relay

Controller

Address

1's

10's

Archive Valid

Port 2a Rx

Port 2a Tx

Port 1 Rx

Port 1 Tx

Battery low

Ext. Batt.

Int. Batt.

External

Battery

Gnd

+3V

Status

Module

3V Lithium Battery

CR-123A

0 = Download required

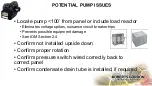

3 = Comm setup error

1 = Control Program Error

4 = System error

8 = Formatting

2 = RAM full

Chase = OK

Status Codes

Class 2

ONLY Use Copper

24Vac, 50VA

Without Keypad:

26Vdc, 23W, 0.9A

Outputs

24Vdc Max, 50mA Max

Format

Pot

2-wire

4-wire

2 wire 4 wire

Rx -

Net-

Net+

n/c

Tx -

Tx +

Rx +

n/c

EIA-232

DCD

Rx

Tx

DTR

Signal Ground

®

BACnet

Over ARCNET156 KBaud

Made in USA

Port 2a BT485

Port 1

Port 1 BT485

Conductors

2A, 50-60 Hz

Blinking Dot = 'Run'

On

Off

Enhanced

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

IP Addr

AssignedDefault

10/100 BaseT

Ethernet Port E1

100

LAN

LINK

®

8

7

6

5

See BAS Table Below

Protocols 6

MS/TP m

MS/TP s

Off

N2

On

Lon SLTA

Off

BAUD

4

5

9600

OffOff

19.2 KOffOn

38.4 KOn

Off

76.8 KOn

On

On

Modbus

8

Off

Off

On

On

Off

4

3

7

Off

On

Off

Off

Off

PTP

Off

Off

On

Access Port 2a

Lon Option Off

On

On

2

1

UO-1

UO-2

UO-3

UO-4

UO-8

UO-7

UO-6

UO-5

On

Off

2

1

BAS Port

BAS Port Settings

Set Pot Full CW

24Vac

DO NOT APPLY 24Vac TO

UNIVERSAL OUTPUTS

External 24Vdc relay coil only

Brownout

3

UO-2

UO-1

2

1

UO-4

UO-3

6

5

4

7

8

6

UO-7

UO-6

UO-5

3

1

2

4

5

UO-8

7

8

+

Gnd

+

Gnd

+

Gnd

+

Gnd

+

Gnd

+

Gnd

+

Gnd

+

Gnd

Aux Power Out

Port 2b

Port 2a

IOPro812u

07/10/12

Rev 6

Open Energy

Management Equipment

26Vdc

ZONE 2

SENSOR

ZONE 1

SENSOR

PRESS.

SW1

V1

PRESS.

SW2

V2

CoRayVac Burners Pump

Operated Zones

G N L

G N L

G N L

G N L

G N L

G N L

NG

G

N

L L LL

N N N N

CB2

20A

G

11

14

12

COM

NO

NC

(A1)

(A2)

11

14

12

COM

NO

NC

(A1)

(A2)

11

14

12

COM

NO

NC

(A1)

(A2)

11

14

12

COM

NO

NC

(A1)

(A2)

N1N1

BLK WHT GRN

L N GND

120V 60HZ

1x 20A

COMMUNICATION

TO

SATELLITE

CONTROLLERS

FIELD

WIRING

REQUIRED

B- Shielded, 1 Twisted,

Stranded

C- Shielded, 2 Twisted,

Stranded

A- Shielded, 1 Twisted,

Stranded

G N L

G N L

G N L

G N L

G N L

G N L

460v - VFD enable signal

2 wire

5

120 VAC

120 VAC

120 VAC

OUTDOOR

SENSOR

-

+

Must Mount on

North wall

TOUCH

SCREEN

AB C DS1S2

Touch Screen comes Factory

Wired- showing for visual only

L1 L2 L3 GND

460V 3x

VFD PWR IN

L2

U1V1W1

U2V2W2

G

G

G

L1

L3

V1

V2

EP-203

EP-203

Line Voltage Output

Line Voltage Output

Line Voltage Input

460 VAC

V2 Load Reactor-

Mount near VFD

enclosure

G N L

G N L

G N L

G N L

ZONE 3

SENSOR

TF Burner

L

N

G

WEST CONTROL PANEL

Summary of Contents for CORAYVAC

Page 1: ...CONTROLS OVERVIEW ...

Page 3: ...CONTROLS INTRODUCTION ...

Page 8: ... Indoor zone sensor ROBERTS GORDON SENSORS Outdoor air sensor ...

Page 9: ...TYPICAL LAYOUT ...

Page 10: ...SITE LAYOUT ...

Page 13: ...CORAYVAC MODULATING DESIGN DRAWING SERVICES ...

Page 15: ...YOU DON T NEED TO KNOW IT ALL ...

Page 17: ...West System East System ...

Page 18: ......

Page 19: ......

Page 20: ......

Page 22: ...INFORMATION DOCUMENTATION WE ASK OF YOU ...

Page 24: ...PRELIMINARY DOCUMENTATION VFD Supply Voltage BMS system protocol if used ...

Page 25: ...DETAILED DOCUMENTATION You provide before placing PO ...

Page 29: ...INSTALLATION REQUIREMENTS THINGS TO AVOID ...

Page 46: ...TOUCH SCREEN ...

Page 50: ...SYSTEM VIEW After Discovery Discover system again for all controllers ...

Page 52: ...SYSTEM VIEW Repeat process for all controllers ...

Page 54: ...SYSTEM VIEW Set Range System Touch can scan network for all MAC addresses ...

Page 55: ...SYSTEM VIEW After Discovery hit Create DB ...

Page 56: ...SYSTEM VIEW Schedule Grouping not required Can do multiple zones with same schedule ...

Page 57: ...SETUP Setup Communications Viewfile Discovery Touchscreen Setup Logout ...

Page 61: ...MAIN MENU ...

Page 62: ...SCHEDULE Controller comes with standard 7AM 5PM Monday Friday schedule for each heating zone ...

Page 64: ...SCHEDULE Select Object to change Zones schedule ...

Page 67: ...MAIN MENU Alarms accessed from Alarms menu Alarm bell on home screen ...

Page 68: ...ALARMS Alarm bell on home screen ...

Page 69: ...ALARMS Clear alarm Check the white box It clear alarm in few second ...

Page 70: ...ALARMS Select System Alarm Buffer Navigates to Manually Cleared or Clear Active screens ...

Page 71: ...CONFIGURATION SERVICE Configuration Service can be set in Menu ...

Page 72: ...CONFIGURATION SERVICE ...

Page 73: ...CONFIGURATION SERVICE ...

Page 74: ...CONFIGURATION SERVICE ...

Page 75: ...CONFIGURATION SERVICE Enter External and Internal design temperature ...

Page 76: ...CONFIGURATION ZONES Run Command ...

Page 77: ...CONFIGURATION ZONES Set Schedule ...

Page 78: ...CONFIGURATION ZONES Set Zone Temperature ...

Page 79: ...CONFIGURATION ZONES Door Switch Enable ...

Page 80: ...CONFIGURATION UNIT ...

Page 81: ...CONFIGURATION UNIT ...

Page 82: ...CONFIGURATION ALARMS Can be set in Menu Note Preconfigured alarm times should not be changed ...

Page 83: ...TOUCH SCREEN SYSTEM Touch Screen System ...

Page 84: ...TOUCH SCREEN SYSTEM Setup ...

Page 85: ...TOUCH SCREEN SYSTEM Module Setup Set Time and Date ...

Page 86: ...TOUCH SCREEN SETUP Touch Screen Setup ...

Page 88: ...TOUCH SCREEN SETUP Sensor Setup Set up System Touch s temperature and humidity sensors ...

Page 93: ...CONTROLLER INTEGRATION ...

Page 101: ...IOM UPDATES Section 12 Integration with Building Management System BMS ...

Page 102: ...EXPLANATION OF MODULATION ...

Page 104: ...OUTSIDE TEMPERATURE HEAT REQUIREMENTS ...

Page 105: ...ON OFF VS MODULATION ...

Page 106: ......

Page 107: ...INCREASED THERMAL EFFICIENCY ...

Page 108: ......

Page 109: ...COMPETITIVE COMPARISONS ...

Page 113: ...COMPETITIVE COMPARISONS VS ...

Page 114: ...HOW TO DOWNLOAD A PROGRAM ...

Page 122: ...HOW TO DOWNLOAD A PROGRAM Launch Apploader Select File Choose RG clipping file Select Open ...

Page 123: ...HOW TO DOWNLOAD A PROGRAM Select Options tab Keep selected default ...

Page 124: ...HOW TO DOWNLOAD A PROGRAM Select Connection tab Select Rnet ...

Page 126: ...HOW TO DOWNLOAD A PROGRAM Select Baud Rate tab Select 115200 ...

Page 127: ...HOW TO DOWNLOAD A PROGRAM Select IP Config Recheck previous selection and select Connect ...

Page 128: ...HOW TO DOWNLOAD A PROGRAM Select Build tab Select Download Memory ...

Page 130: ...HOW TO DOWNLOAD A PROGRAM Select OK Wait for program to finish downloading 15 minutes ...

Page 131: ...HOW TO DOWNLOAD A PROGRAM Select Modstat Save results Close AppLoader ...

Page 132: ...HOW TO RELOAD TOUCH PAD FIRMWARE ...

Page 137: ...VFD TROUBLESHOOTING ...

Page 140: ...VFD TROUBLESHOOTING Does VFD have power 120 230 or 460V between any 2 inputs on VFD ...

Page 147: ...IOM UPDATES Section 9 Troubleshooting ...

Page 148: ...TOUCH PAD TROUBLESHOOTING ...

Page 151: ...IOM UPDATES Section 9 Troubleshooting ...

Page 152: ...ZONE SENSOR VACUUM PUMP TROUBLESHOOTING ...

Page 157: ...IOM UPDATES Section 9 Troubleshooting ...

Page 158: ...REPEATER TROUBLESHOOTING ...

Page 160: ...REPEATER TROUBLESHOOTING Sample network configuration using MS TP ...

Page 162: ...REPEATER TROUBLESHOOTING Hybrid configuration ...