SECTION 1: I

NTRODUCTION

1

SECTION 1: INTRODUCTION

1.1 Safety

Your Safety is Important to Us!

This symbol is used throughout

the manual to notify you of

possible fire, electrical or burn

hazards. Please pay special atten-

tion when reading and following

the warnings in these sections.

Installation, service and annual inspection of

controller must be done by an electrician qualified in

the installation and service of control systems for

heating equipment.

Installation, service and annual inspection of heater

must be done by a contractor qualified in the

installation and service of gas-fired heating

equipment.

Read this manual carefully before installation,

operation, or service of this equipment.

The appliance must be applied and operated under

the general concepts of reasonable use and installed

using best building practices.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowl-

edge, unless they have been given supervision or

instruction concerning use of the appliance by a per-

son responsible for their safety.

Children should be supervised to ensure that they do

not play with the appliance.

For optimum heater performance and safe heating

conditions, inspect and maintain heater(s) before

every heating season and as necessary. Also, know

and maintain heater clearances to combustibles, see

heater Installation, Operation and Service Manual for

further details. If you require additional manuals, con-

tact your ROBERTS GORDON

®

independent distrib-

utor or Roberts-Gordon LLC at (716) 852-4400, (800)

828-7450 or at www.robertsgordon.com.

1.2 Safety Labels and Their Placement

Product safety signs or labels should be replaced by

the product user when they are no longer legible.

Please contact Roberts-Gordon LLC or your ROB-

ERTS GORDON

®

independent distributor to obtain

replacement signs or labels.

1.3 California Proposition 65

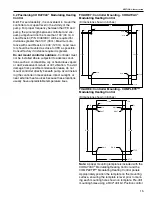

In accordance with California Proposition 65 require-

ments, a warning label must be placed in a highly

visible location on the outside of the equipment (i.e.,

near equipment’s serial plate). See label placement

drawings

for label location. Avoid placing label on areas with

extreme heat, cold, corrosive chemicals or other ele-

ments. To order additional labels, please contact

Roberts-Gordon LLC or your ROBERTS GORDON

®

independent distributor.

1.4 What is a ROBERTS GORDON

®

CORAYVAC

®

Modulating Heating Control?

The ROBERTS GORDON

®

CORAYVAC

®

Modulating

Heating Control is a micro-processor based control

package designed for modulating control of CORAY-

VAC

®

system and/or control of ROBERTS GOR-

DON

®

modulating and single stage unitary heaters

based on outdoor temperatures.

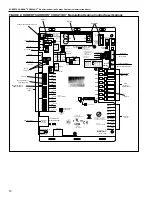

This controller is capable of giving control outputs to

two vacuum pumps and four heating zones. The con-

troller also features inputs which are used for indoor

and outdoor signal condition monitoring.

For the overall view of connected components for

ROBERTS GORDON

®

CORAYVAC

®

Modulating

Heating Control,

.

System status and settings are viewed and altered

from a touchscreen, personal computer or smart

device (PC and smart device not supplied).

1.5 What is a ROBERTS GORDON

®

COMPLETE™

Modulating Heating Control?

Similar to the CORAYVAC

®

Modulating Heating Con-

trol, The ROBERTS GORDON

®

COMPLETE™ Mod-

ulating Heating Control is a micro-processor based

control package designed for modulating control of

VANTAGE

®

Modulating (model: CTH3/HEM) unitary

heaters, on/off control of single-stage ROBERTS

GORDON

®

unitary heaters, or on/off control of

CORAYVAC

®

or VANTAGE

®

Multiburner systems.

This controller is capable of giving control outputs to

two vacuum pumps and four heating zones. The con-

troller also features inputs which are used for indoor

and outdoor signal condition monitoring.

System status and settings are viewed and altered

from a touchscreen, personal computer, or smart

device (PC and smart device not supplied).

Summary of Contents for CORAYVAC

Page 2: ......

Page 4: ......

Page 69: ...SECTION 8 PROGRAMMING AND TROUBLESHOOTING THE SYSTEM 65 THIS PAGE LEFT INTENTIONALLY BLANK ...

Page 71: ...SECTION 9 TROUBLESHOOTING 67 FIGURE 26 Vacuum pump does not turn on ...

Page 75: ...SECTION 9 TROUBLESHOOTING 71 FIGURE 31 Burner troubleshooting in manual mode ...

Page 77: ...SECTION 9 TROUBLESHOOTING 73 After 45 second prepurge burners do not light continued ...

Page 81: ...SECTION 9 TROUBLESHOOTING 77 FIGURE 36 Air Pressure Switch alarm ...

Page 83: ...SECTION 9 TROUBLESHOOTING 79 FIGURE 38 Repeater troubleshooting ...

Page 85: ...SECTION 9 TROUBLESHOOTING 81 BACnet MS TP troubleshooting continued ...

Page 109: ...SECTION 13 TOUCHSCREEN TREE 105 Touchscreen Tree Overview continued ...

Page 111: ...SECTION 13 TOUCHSCREEN TREE 107 FIGURE 47 Maintenance Unit FIGURE 48 Alarms ...

Page 113: ...SECTION 13 TOUCHSCREEN TREE 109 FIGURE 51 Configuration Zones FIGURE 52 Configuration Unit ...

Page 115: ...SECTION 13 TOUCHSCREEN TREE 111 FIGURE 55 Touchscreen System FIGURE 56 Touchscreen Setup ...

Page 118: ...ROBERTS GORDON CORAYVAC MODULATING HEATING CONTROL CONTROLLER INSTALLATION MANUAL 114 ...