SECTION 7: C

OMMISSIONING

T

HE

CORAYVAC

®

S

YSTEM

55

SECTION 7: COMMISSIONING THE CORAYVAC

®

SYSTEM

Note:

The ROBERTS GORDON

®

CORAYVAC

®

Mod-

ulating Heating Control central controller is fitted with

a touchscreen for communication to the CORAY-

VAC® system and all CORAYVAC® Modulating

Heating Control satellite controllers (maximum of 31

controllers before a repeater is needed). All wiring

and control board setup must be complete prior to

commissioning the system.

7.1 Setting The CORAYVAC

®

End Burner Vacuum

It is important to understand that the frequency that

the VFD runs the motor at, determines the speed of

the impeller in the pump. Variation of the impeller

speed will increase or decrease vacuum in the sys-

tem. The following procedure will help you set mini-

mum and maximum VFD frequency settings to

achieve proper vacuum in the system.

Step 7.1.1 Note:

The VFD(s) should be programmed

using the procedure and parameters described on

prior to this step. At the VFD, press and hold "OK"

until P-01 appears. This will allow access to the PRO-

GRAM mode to adjust parameters. Using the arrow

button, scroll to P-12 and set parameter to "01". Press

"OK" to store new setting. Press "START" button on

VFD to turn on the CORAYVAC® vacuum pump.

Pump should ramp up to value set in P-01. Verify

pump rotation. Pump impeller should be rotating in

direction of arrow stamped on vacuum pump hous-

ing.

On the control board, switch the relevant "HOA"

switches to "Manual On" position to turn on the zones

connected to the vacuum pump.

for control board layout.

Note:

The vacuum pump must be energized prior to

manually switching on the zones.

Step 7.1.2

The pump should be running and the burn-

ers should light within 60 seconds. At the VFD, verify

that the number displayed on the LCD screen is

"60.0" If it is lower than 60.0, hit the "up" arrow button

on the VFD until the number reads 60.0 Let the burn-

ers fire for approximately 20-30 minutes to warm up

the system. Using a manometer, check the end vent

vacuum in each zone (each branch of burners).

If the lowest end vent vacuum reading is above 3.0"

w.c., reduce the vacuum pump speed. Generally, the

lowest end vent vacuum reading is on the longest

branch of the system. Use the down arrow button on

the VFD to reduce the frequency of the output signal

to the pump, thus reducing the pump speed and low-

ering the end vent vacuum reading. Continue to

reduce the frequency until the end vent vacuum read-

ing is between 2.5" - 3.0" w.c. Make note of this fre-

quency setting below. The frequency is found on the

VFD’s LCD screen.

2.5" w.c. - 3.0" w.c. VFD Frequency Setting

To avoid damage to the pump motor, do not adjust

the frequency above 60.0 Hz. Verify that the end vent

vacuum readings in the remaining branches are

proper. If necessary, adjust the proper damper cou-

pling to achieve an end vent vacuum of 2.5" - 3.0"

w.c.

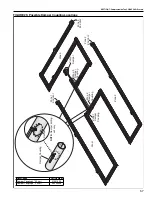

. Damper couplings

should be found near the end of the radiant portion of

the pipe in each branch or where a branch connects

to other branches at a cross or tee.

.

Step 7.1.3

After setting end vent vacuums between

2.5" w.c. and 3.0" w.c., while all the burners are still

operating, use the down arrow button on the VFD to

reduce the frequency of the output signal to the

pump. Reduce the frequency of the VFD until the

manometer at each of the end vents reads 1.2" w.c. -

1.5" w.c., Make note of this frequency setting below.

The frequency is found on the VFD’s LCD screen.

1.2" w.c. - 1.5" w.c. VFD Frequency Setting

Step 7.1.4

Press the "STOP" button on VFD. Return

"HOA" switches to "Auto".

Step 7.1.5

Using the procedure described on

, alter parameters "P-01" and "P-02" to

maximum and minimum frequency settings. Return

parameter "P-12" to "03".

Record Frequency Setting Here:

Record Frequency Setting Here:

Summary of Contents for CORAYVAC

Page 2: ......

Page 4: ......

Page 69: ...SECTION 8 PROGRAMMING AND TROUBLESHOOTING THE SYSTEM 65 THIS PAGE LEFT INTENTIONALLY BLANK ...

Page 71: ...SECTION 9 TROUBLESHOOTING 67 FIGURE 26 Vacuum pump does not turn on ...

Page 75: ...SECTION 9 TROUBLESHOOTING 71 FIGURE 31 Burner troubleshooting in manual mode ...

Page 77: ...SECTION 9 TROUBLESHOOTING 73 After 45 second prepurge burners do not light continued ...

Page 81: ...SECTION 9 TROUBLESHOOTING 77 FIGURE 36 Air Pressure Switch alarm ...

Page 83: ...SECTION 9 TROUBLESHOOTING 79 FIGURE 38 Repeater troubleshooting ...

Page 85: ...SECTION 9 TROUBLESHOOTING 81 BACnet MS TP troubleshooting continued ...

Page 109: ...SECTION 13 TOUCHSCREEN TREE 105 Touchscreen Tree Overview continued ...

Page 111: ...SECTION 13 TOUCHSCREEN TREE 107 FIGURE 47 Maintenance Unit FIGURE 48 Alarms ...

Page 113: ...SECTION 13 TOUCHSCREEN TREE 109 FIGURE 51 Configuration Zones FIGURE 52 Configuration Unit ...

Page 115: ...SECTION 13 TOUCHSCREEN TREE 111 FIGURE 55 Touchscreen System FIGURE 56 Touchscreen Setup ...

Page 118: ...ROBERTS GORDON CORAYVAC MODULATING HEATING CONTROL CONTROLLER INSTALLATION MANUAL 114 ...