ROBERTS GORDON

®

CORAYVAC

®

M

ODULATING

H

EATING

C

ONTROL

C

ONTROLLER

I

NSTALLATION

M

ANUAL

2

1.6 General Requirements

The ROBERTS GORDON

®

CORAYVAC

®

Modulating

Heating Control series of controllers are supplied pre-

configured for use with ROBERTS GORDON

®

CORAYVAC

®

infrared heating equipment only. Fail-

ure to comply with the installation instructions and

configuration may invalidate the ROBERTS GOR-

DON

®

CORAYVAC

®

Modulating Heating Control lim-

ited warranty.

The controller, variable frequency drive, burners,

pump and outside air blower must be electrically

grounded in accordance with the National Electrical

Code

®

ANSI/NFPA 70 - latest revision.

Before proceeding with the installation of the control-

ler, it will be necessary to check that the following

points have been considered:

1.7 CORAYVAC

®

Design Requirements

(Modulating Systems)

CORAYVAC

®

burners shall be CRV B-6, B-8, B-9,

B-10 or B-12 burners.

CORAYVAC

®

systems designed shall have

minimum

radiant pipe length and 1.5 - 2.0’ per flow

unit of tailpipe length.

-OR-

CORAYVAC

®

systems designed shall have

recommended

radiant pipe length and 1.2 - 1.5’ per

flow unit of tailpipe length. See the CORAYVAC

®

Design Manual (P/N 127500NA) for minimum and

recommended radiant pipe length.

1.8 CORAYVAC

®

Design Requirements (On/Off

Systems)

CORAYVAC

®

burners shall be CRV B-2, B-4, B-6, B-

8, B-9, B-10, B-12A, or B-12 burners.

Radiant and tail pipe lengths shall comply with

design requirements specified in CORAYVAC

®

Design Manual (P/N 127500NA).

and

for

on/off system specific setup.

Note: Use COMPLETE™ Modulating Heating Con-

trol (P/N 10060042 or 10060142) for these installa-

tions.

1.9 VANTAGE

®

CTHN Multiburner Systems

Burners shall be VANTAGE

®

CTHN.

Radiant and manifold pipe lengths shall comply with

design requirements specified in VANTAGE

®

CTHN

Installation, Operation, and Service Manual (P/N

152101NA).

Note: Use COMPLETE™ Modulating Heating Con-

trol (P/N 10060042 or 10060142) for these installa-

tions.

1.10 Unitary Design Requirements

Burners shall be VANTAGE

®

CTH3, HEM, CTH2V,

HEV, TF, CTHN or GORDONRAY

®

BH. Only VAN-

TAGE

®

CTH3/HEM burners will modulate. All other

burners will operate as on/off.

Note: GORDONRAY

®

DF (two-stage unitary heater)

will not function with CORAYVAC

®

or COMPLETE™

Modulating Heating Control.

1.11 Control Board and Sensor Power

The power supply for all sensors is from the “+12 V”

terminal on the Rnet port of control board. Power for

the control board is 24 V provided by the transformer.

DANGER

Electrical Shock Hazard

Disconnect electric before service.

Controller must be properly grounded to an

electrical source.

Failure to follow these instructions can

result in death or electrical shock.

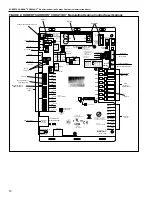

88F0

E143900

TYPE: 002003

Power

Off On

Power

Gnd

24Vac

Port 1

485

ARC-

Shield

Net -

Net +

156

Port 2a

Rnet

Gnd

Rnet +

Rnet -

+12V

Xnet +

Xnet -

Gnd

Xnet Expansion

Local

Rnet+

Gnd

Sense

+12V

Rnet-

Access

EIA-485

EIA-232

Thermistor/

dry-contact/

Mode Select

Universal Input

mA

RTD

Volts

10V Max, 20mA Max

Inputs: All

UI-4

UI-3

UI-2

UI-1

Gnd

+

Gnd

Gnd

+

+

Gnd

+

8

7

6

5

4

3

2

1

UI-8

Gnd

UI-6

UI-7

UI-5

Gnd

+

+

Gnd

+

Gnd

+

UI-12

UI-11

UI-10

UI-9

+

Gnd

+

Gnd

Gnd

+

Gnd

+

24 Vdc

24 Vdc

200mA maximum

Auto Off On

0-20mA

0-10Vdc

Relay

Controller

Address

1's

10's

Archive Valid

Port 2a Rx

Port 2a Tx

Port 1 Rx

Port 1 Tx

Battery low

Ext. Batt.

Int. Batt.

External

Battery

Gnd

+3V

Status

Module

3V Lithium Battery

CR-123A

0 = Download required

3 = Comm setup error

1 = Control Program Error

4 = System error

8 = Formatting

2 = RAM full

Chase = OK

Status Codes

Class 2

ONLY Use Copper

24Vac, 50VA

Without Keypad:

26Vdc, 23W, 0.9A

Outputs

24Vdc Max, 50mA Max

Format

Pot

2-wire

4-wire

2 wire4 wire

Rx -

Net-

Net+

n/c

Tx -

Tx +

Rx +

n/c

EIA-232

DCD

Rx

Tx

DTR

Signal Ground

®

BACnet

Over ARCNET156 KBaud

Made in USA

Port 2a BT485

Port 1

Port 1 BT485

Conductors

2A, 50-60 Hz

Blinking Dot = 'Run'

On

Off

Enhanced

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

IP Addr

Assigned Default

10/100 BaseT

Ethernet Port E1

100

LAN

LINK

®

8

7

6

5

See BAS Table Below

Protocols 6

MS/TP m

MS/TP s

Off

N2

On

Lon SLTA

Off

BAUD 4

5

9600 Off

Off

19.2 K Off

On

38.4 K On Off

76.8 K On

On

On

Modbus

8

Off

Off

On

On

Off

4

BACnet

3

7

Off

On

Off

Off

Off

PTP

Off

Off

On

Access Port 2a

Lon OptionOff

On

On

2

1

UO-1

UO-2

UO-3

UO-4

UO-8

UO-7

UO-6

UO-5

On

Off

2

1

BAS Port

BAS Port Settings

Set Pot Full CW

24Vac

DO NOT APPLY 24Vac TO

UNIVERSAL OUTPUTS

External 24Vdc relay coil only

Brownout

3

UO-2

UO-1

2

1

UO-4

UO-3

6

5

4

7

8

6

UO-7

UO-6

UO-5

3

1

2

4

5

UO-8

7

8

+

Gnd

+

Gnd

+

Gnd

+

Gnd

+

Gnd

+

Gnd

+

Gnd

+

Gnd

Aux Power Out

Port 2b

Port 2a

IOPro812u

07/10/12

Rev 6

Open Energy

Management Equipment

26Vdc

Summary of Contents for CORAYVAC

Page 2: ......

Page 4: ......

Page 69: ...SECTION 8 PROGRAMMING AND TROUBLESHOOTING THE SYSTEM 65 THIS PAGE LEFT INTENTIONALLY BLANK ...

Page 71: ...SECTION 9 TROUBLESHOOTING 67 FIGURE 26 Vacuum pump does not turn on ...

Page 75: ...SECTION 9 TROUBLESHOOTING 71 FIGURE 31 Burner troubleshooting in manual mode ...

Page 77: ...SECTION 9 TROUBLESHOOTING 73 After 45 second prepurge burners do not light continued ...

Page 81: ...SECTION 9 TROUBLESHOOTING 77 FIGURE 36 Air Pressure Switch alarm ...

Page 83: ...SECTION 9 TROUBLESHOOTING 79 FIGURE 38 Repeater troubleshooting ...

Page 85: ...SECTION 9 TROUBLESHOOTING 81 BACnet MS TP troubleshooting continued ...

Page 109: ...SECTION 13 TOUCHSCREEN TREE 105 Touchscreen Tree Overview continued ...

Page 111: ...SECTION 13 TOUCHSCREEN TREE 107 FIGURE 47 Maintenance Unit FIGURE 48 Alarms ...

Page 113: ...SECTION 13 TOUCHSCREEN TREE 109 FIGURE 51 Configuration Zones FIGURE 52 Configuration Unit ...

Page 115: ...SECTION 13 TOUCHSCREEN TREE 111 FIGURE 55 Touchscreen System FIGURE 56 Touchscreen Setup ...

Page 118: ...ROBERTS GORDON CORAYVAC MODULATING HEATING CONTROL CONTROLLER INSTALLATION MANUAL 114 ...