ROBERTS GORDON

®

CORAYVAC

®

M

ODULATING

H

EATING

C

ONTROL

C

ONTROLLER

I

NSTALLATION

M

ANUAL

94

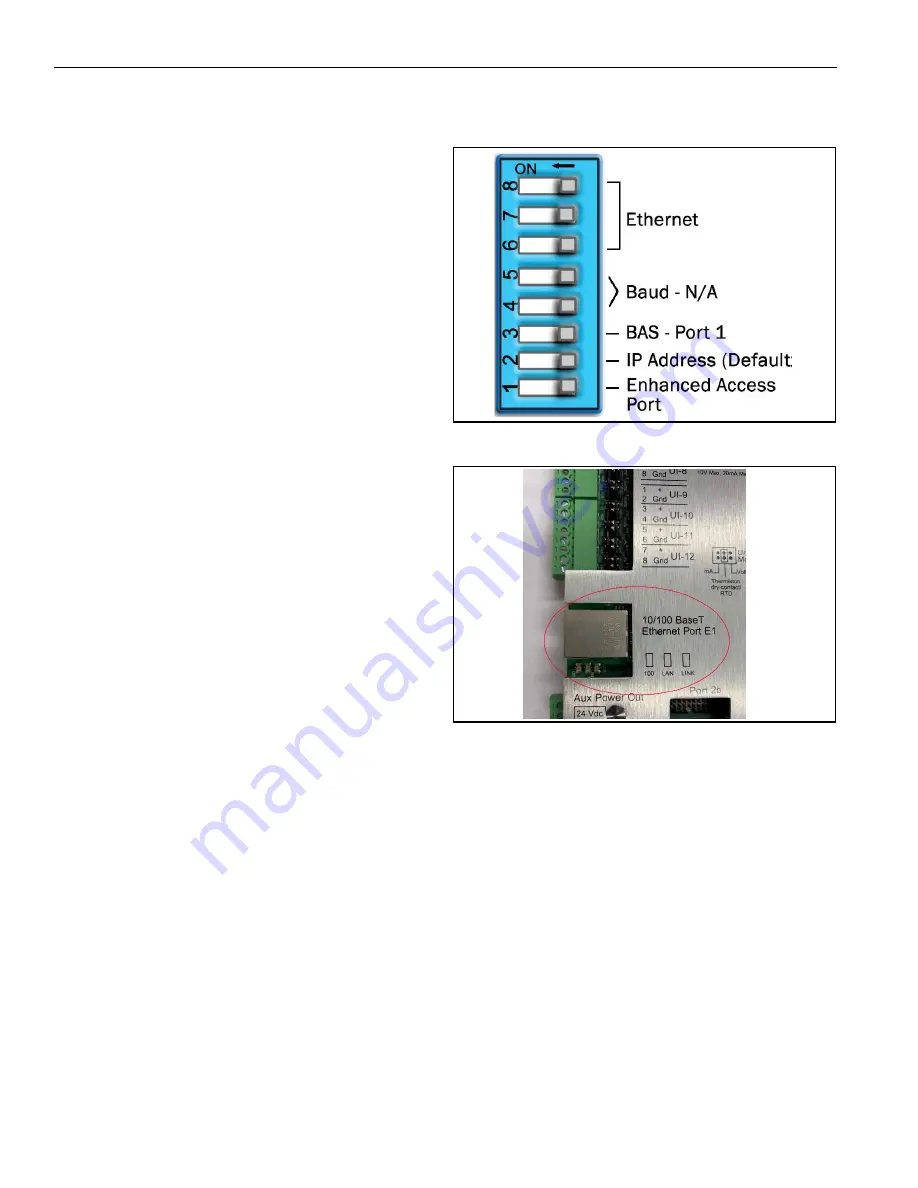

9. Set the following DIP switch on the modem

10. Turn on power to the control board.

Note:

The most common communication problems

are the result of not properly following the

configuration steps outlined in this manual. Review

all the steps and use the following list to check your

settings.

Verify accuracy of the following:

Hardware settings for speaking BACnet PTP

• Baud rate DIP switches 4 and 5

• Protocol DIP switches 6, 7, and 8 Jumper set to

EIA-232

• Proper connection wiring

• Unique rotary address switches 1 – 99. If control-

lers have duplicate addresses, network communi-

cation can be lost.

• Unique BACnet Device Instance numbers. Default

is 24XX, with the rotary address switches defining

XX. If controllers have duplicate device instance

numbers, network communication can be lost.

• Do not power the PTP-speaking device from the

same transformer that powers the I/O Pro 812u.

• If RX LED is solid, then the terminations are incor-

rect.

• The controller recognizes physical changes (DIP

switches, rotary switches, and jumpers) upon

power up.

12.4 BACnet Over IP

This is used for tunneling BACnet packets inside of

IP (Internet Protocol) packets for carrying BACnet

messages over wide-area networks and the Internet.

This network layer offers the fastest speed and

allows for communication of BACnet on the highest

network layer. Although the speed is very fast, there

is a lot of overhead required in this kind of network

topology. Overhead refers to information inside the

data packet/message being passed over the

network, requiring expensive high-speed computing

processors.

To set up the Modulating Controller for BACnet

over IP (default IP)

1. Turn off power to control board.

2. Using the rotary switches, set the controller's

address.

3. Set the Tens (10's) switch to the tens digit of the

address and set the Ones (1's) switch to the ones

digit.

Note:

The default address is an intranet address.

Data packets from this address is not routable to the

Internet.

4. Connect Port E1, which is the only port that

speaks BACnet over IP.

Wiring Specifications

• Maximum cable length 328’ (100 m).

• Use one of the following CAT5 or higher Ethernet

cables:

o

A cross-over cable to connect the

controller directly to the third-party device.

o

A straight-through cable to connect the

controller to a hub or switch, and a second

straight-through cable to connect the hub

or switch to the third-party device.

NOTE

: Use the same polarity throughout the network

segment.

5. Turn on power to control board.

6. Set the IP address using a Touch Screen.

Summary of Contents for CORAYVAC

Page 2: ......

Page 4: ......

Page 69: ...SECTION 8 PROGRAMMING AND TROUBLESHOOTING THE SYSTEM 65 THIS PAGE LEFT INTENTIONALLY BLANK ...

Page 71: ...SECTION 9 TROUBLESHOOTING 67 FIGURE 26 Vacuum pump does not turn on ...

Page 75: ...SECTION 9 TROUBLESHOOTING 71 FIGURE 31 Burner troubleshooting in manual mode ...

Page 77: ...SECTION 9 TROUBLESHOOTING 73 After 45 second prepurge burners do not light continued ...

Page 81: ...SECTION 9 TROUBLESHOOTING 77 FIGURE 36 Air Pressure Switch alarm ...

Page 83: ...SECTION 9 TROUBLESHOOTING 79 FIGURE 38 Repeater troubleshooting ...

Page 85: ...SECTION 9 TROUBLESHOOTING 81 BACnet MS TP troubleshooting continued ...

Page 109: ...SECTION 13 TOUCHSCREEN TREE 105 Touchscreen Tree Overview continued ...

Page 111: ...SECTION 13 TOUCHSCREEN TREE 107 FIGURE 47 Maintenance Unit FIGURE 48 Alarms ...

Page 113: ...SECTION 13 TOUCHSCREEN TREE 109 FIGURE 51 Configuration Zones FIGURE 52 Configuration Unit ...

Page 115: ...SECTION 13 TOUCHSCREEN TREE 111 FIGURE 55 Touchscreen System FIGURE 56 Touchscreen Setup ...

Page 118: ...ROBERTS GORDON CORAYVAC MODULATING HEATING CONTROL CONTROLLER INSTALLATION MANUAL 114 ...