- 59 -

Installation has a decisive in

fl

uence on engine life, ease of maintenance and inspection, frequency of inspection

and repair, running costs and other related aspects. Before installing the engine, be sure to plan the installation

with care, taking the points below into account.

14-1 INSTALLING

When installing the engine, pay special attention to the position of installation, the method for coupling with

working equipment, and the foundations and supports for the engine. Position the engine so that tasks such as

gasoline and oil replenishment and inspection, spark plug inspection, air cleaner maintenance, oil drainage and so

on can be carried out as easily as possible.

14-2 VENTILATION

An engine requires fresh air for cooling and for burning fuel. When an engine is covered with a bonnet or is

operated in an enclosed space, the temperature around the engine rises and this causes such problems as vapor

lock, oil deterioration, increased oil consumption, power loss, engine seizure, and reduced engine life, making it

dif

fi

cult for the engine to function normally. It is thus necessary to install ducts and dampers to guide fresh air, so

as not to recycle the hot air used to cool the engine and to prevent the working equipment from heating up.

Be sure to keep the engine room temperature below 50°C all year round and to prevent the accumulation of hot

air in the engine room.

14-3 EXHAUST EQUIPMENT

Exhaust gas is noxious. When operating the engine indoors, make sure that exhaust gases are discharged

outdoors. However, if the exhaust pipe is long, resistance increases and this lowers engine output. Therefore, the

longer the exhaust pipe the larger its inner diameter should be.

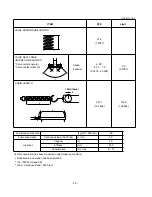

Exhaust pipe length: Less than 3 m

Pipe inner diameter: 30 mm

Exhaust pipe length: 3 - 5 m

Pipe inner diameter: 33 mm

The ideal solution is forced exhaustion (outdoors) by installing a blower on the exhaust pipe.

※

Install a safety cover on the exhaust pipe, muf

fl

er and other related parts.

14-4 FUEL SYSTEM

If the fuel tank is detached from the engine, the height from the bottom of the fuel tank to the fuel joint of the

carburetor should be between 5 cm and 50 cm.

When using a fuel pump, the bottom of the fuel tank can be up to 20 cm below the carburetor. Position the fuel

tank carefully because, when it is low, fuel is not fed to the carburetor and when it is high, it can cause an over

fl

ow

in the carburetor. When piping the fuel, the hose should be as short as possible and attention should be paid to

heat transmission, size, bending, leakage at hose joints and so on. Care should also be taken to prevent air lock

and vapor lock.

14. INSTALLATION

Summary of Contents for EX30

Page 1: ...SERVICE MANUAL EX30 ENGINES Model PUB ES2268 Rev 10 06 ...

Page 77: ......

Page 78: ...PRINTED IN THE USA ...