– 34 –

Recoil starter

hundle

Guide

Overflow pipe

Case body

Control panel

Mount

Case body

Tightening torque : 3.0-4.0

N

・

m

30-40

kgf

・

cm

(2.2-2.9 ft

・

lbs)

Tightening torque : 3.0-4.0

N

・

m

30-40

kgf

・

cm

(2.2-2.9 ft

・

lbs)

Tightening torque : 2.0-3.0

N

・

m

20-30

kgf

・

cm

(1.5-2.2 ft

・

lbs)

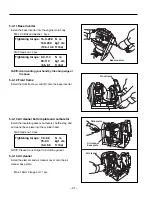

5-4-21 Case body, control panel

Attach the case body (left and right). Install the bottom

part of the case body and the mount together.

M6 x 18mm Flange bolt : 4pcs.

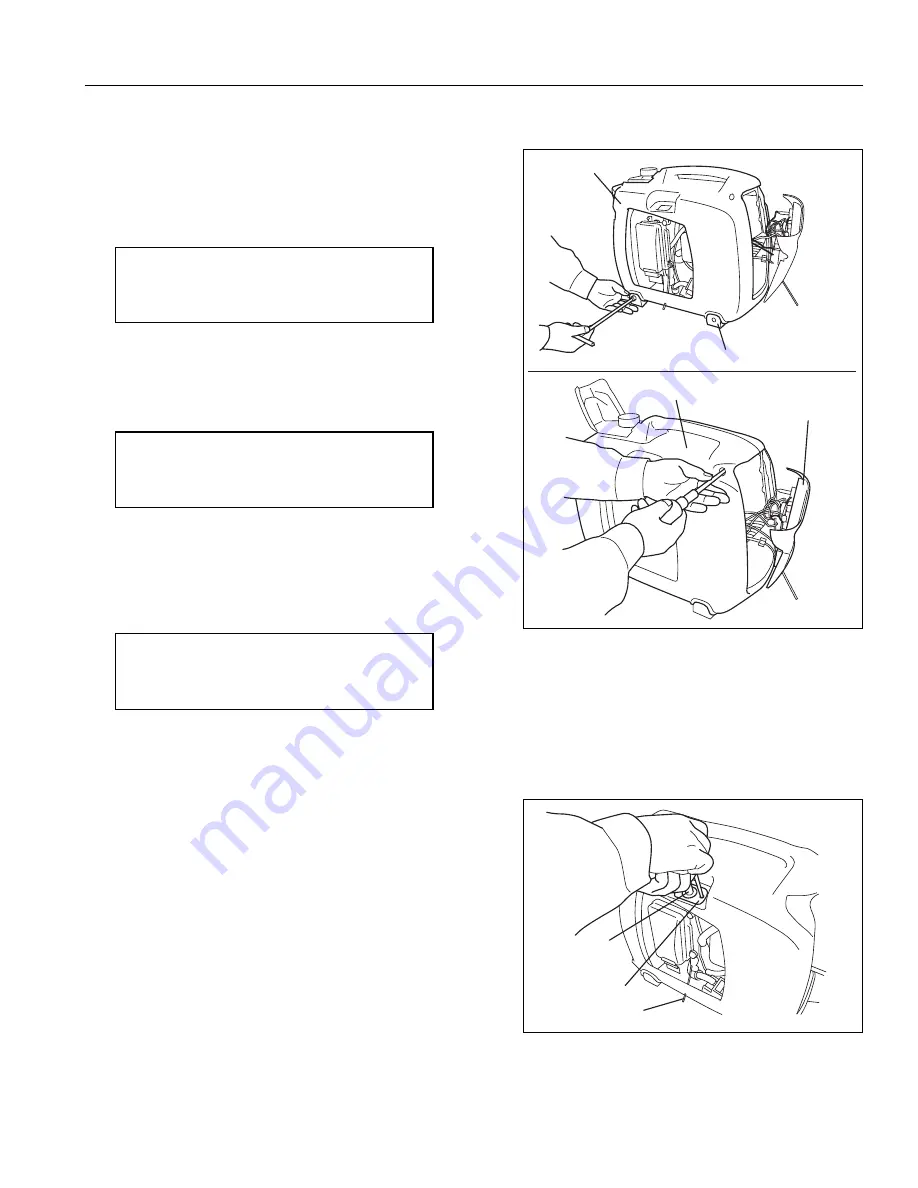

5-4-22 Recoil starter and guide

Install the guide of the starter hundle.

Install the guide and starter hundle after they are

pushed through the mounting hole from inside of the

case body.

M4 x 10mm Tapping screw : 1pcs.

Insert the overflow pipe through the hole in the bottom

of the case body.

Attach the upper part of the case body.

M6 x 25 Screw and Washer : 2pcs.

Install the control panel into the case body.

M4 x 14mm Screw

:

4pcs.

M5 x 8mm Screw

:

4pcs.

NOTE: Avoid gaps in the upper part of the case body

when installing.

NOTE: Install the bottom part of the case body

correctly.

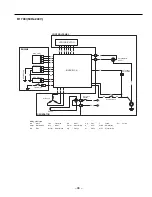

Summary of Contents for R1700i

Page 1: ...SERVICE MANUAL R1700i Model PUB GS1950 Rev 09 04 GENERATOR ...

Page 2: ......

Page 51: ......