– 16 –

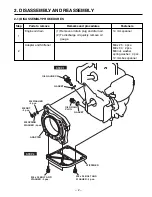

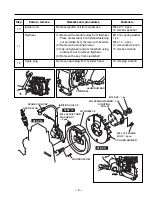

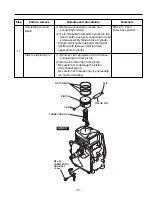

2-2-5 CONNECTING ROD

(1) Turn crankshaft to bottom dead center, lightly tap

top of the piston until large end of the rod meet

crank pin.

(2) Install connecting rod cap to connecting rod.

Attach connecting rod cap to connecting rod so

that the "MA" marking is faced upwards and the

splasher is located on the left-hand side.

Tighten connecting rod bolts to the specification.

M5 x 25 mm connecting rod bolt : 2 pcs.

(3) Check for free movement of connecting rod by

turning crankshaft slowly.

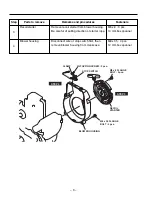

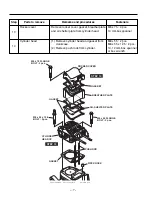

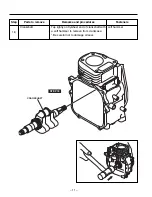

2-2-6 TAPPETS AND CAMSHAFT

(1) Oil the tappets and install them.

Push in fully to avoid damage during

camshaft installation.

(2) Lubricate bearing surfaces of camshaft.

(3) Align the timing mark on crankshaft gear with the

timing mark on camshaft and install camshaft in

the crankcase.

CAUTION:

Incorrect valve timing will cause malfunction

of the engine.

Tightening torque

6 - 8 N•m

(60 - 80 kgf•cm)

(4.3 - 5.7 ft•lb.)

M

A

"MA" MARK

SPLASHER

LEFT SIDE

TIMING MARK

CRANKSHAFT

GEAR

CAMSHAFT