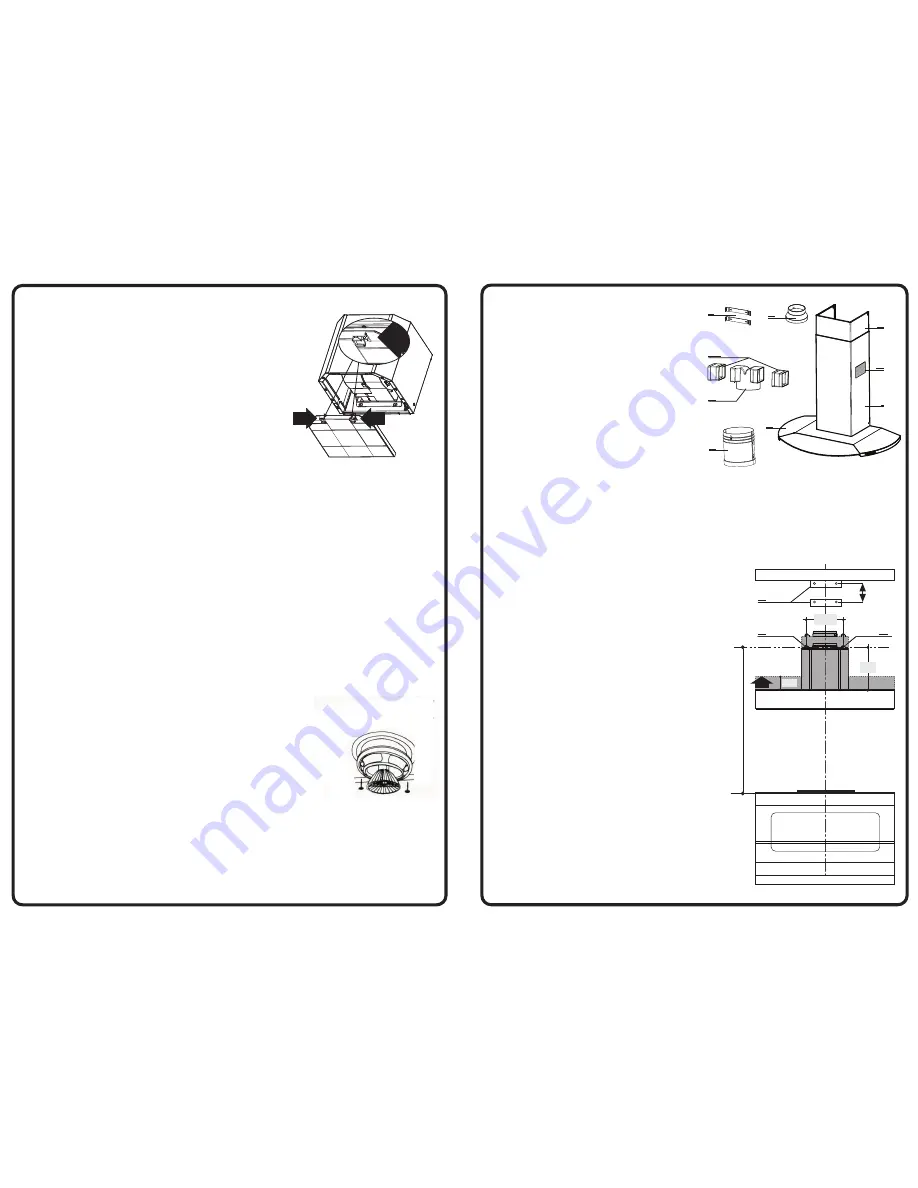

Fig. 13

- 6 -

- 3 -

104574 Issue D

ECN: 07 007

For easy installation, proceed as follows:

Fix the wall brackets

Fix the canopy

Electrical connection and working test

Ducting or Recirculation fitting

Fix the telescopic chimney

Fitting the wall brackets

Please refer to (fig.2):

Ensure the

correct vertical alignment of the

various parts.

Fixing the wall brackets item

2

:

a) Place one of the brackets

2

against the

wall approximately 1 or 2mm from the

ceiling or from the top limit, aligning its

centre (slot) with the vertical line.

b) Mark the centres of two slots in the

bracket on the wall.

c) Rest the other bracket

2

against the

wall,

aligning it with the vertical line, with

the centres of the holes 180mm apart.

d) Mark the centres of the slot in the

bracket

on the wall.

Drilling fixing holes item

1

:

a) Mark a point on the vertical line at a

distance of 982mm (min) from the

cooking appliances.

b) At the point marked, draw a horizontal

line parallel to the cooking appliances.

c) Drill two holes in the wall

1

using an 8 mm

drill bit (fig.2), and insert the rawl plugs and

screws

into the holes (4.2 x 44.4 screws).

Fix the screws, leaving a space of 5-6mm

required

to hook up the canopy. Small

adjustments can be made using the hood

adjustment screws(see Fitting the canopy).

The hood should have a maximum excursion

of 20mm.

(Note: it may be neccesary to change the type

fixing elements depending on wall construction)

Active carbon filter

Operation

The activated charcoal filter when fitted

will retain odours until it becomes saturated.

It cannot be washed or regenerated and

must be replaced when the Intensive Speed

LED

T5

starts to flash,or at least once every

four months of use.

WARNING: In recirculation type hoods the

T2

Motor LED may start to flash as well as the

T5

LED. This indicates that as well as

replacing the activated charcoal filter,it is

also necessary to perform maintenance

operations on the metal grease filters

(see paragraph Metal grease Filter ).

Replacing

Take off the metal grease filters (fig.11) and

remove the activated charcoal filter from its

housing by turning the clips provided ( fig.12). Fit

the new activated charcoal filter and replace the

metal grease filters.

Enabling the alarm signal In recirculation type hoods

the saturated filters alarm must be enabled as indicated

below:

Turn off the lights

T1

and the Suction Motor

T2

;

Press and hold the button

T4

for at least 10 seconds,

until the Leds start to flash.Note the number of flashes:

Two flashes of the LED Activated charcoal filter

saturation alarm ENABLED

One flash of the LED Activated charcoal filter

saturation alarm DISABLED

Resetting the alarm signal To turn the alarm signal off,

proceed as follows:

Press the button

T4

and hold for at least 3 seconds,

until the Led flashes to confirm. Note: the saturated

filters alarm will only come into operation when the

suction motor is turned on.

WARNING - There could be a possible fire hazard if the filters are not

replaced according to these instructions.

Fig. 12

Lighting

Halogen spotlights:

two 20w halogen spotlights.

To replace (fig.13)

Remove the two screws fixing the metal ring, extract

the spotlight from the lamp holder by pulling gently.

When replacing the spotlight, make sure that the two

pins are correctly inserted in the housing on the lamp

holder.

Cleaning

When cleaning the hood:

Never use a wet cloth or sponge, or running water.

Never use thinners or products containing alcohol,

as they might damage any printing.

Never use abrasive cleaning materials, in particular

when cleaning stainless steel surfaces.

It is recommended to use a damp cloth and mild

liquid household cleaner.

Components

The hood comprises the following

(fig.1):

1 canopy

C

complete with controls,

lighting and ventilator unit

1 telescopic chimney, comprising:

1 upper chimney element

S

1 lower chimney element

I

2 directional grills

G

1 reduction flange Ø150-120

A

1 recirculation spigot

R

2 additional side recirculation

spigots

P1

1 additional recirculation spigot

P

1 bag containing:

2 brackets

2

to fix the chimney,

screws, rawl plugs.

Fig. 1

2

A

R

P1

D

G

V

S

I

C

P

Fig. 2

232

260

1

1

2

260

1

1

232

260

1

1

2

260

1

1

20

X

d = 982 min

180