104574 Issue D

ECN: 07 007

- 5 -

- 4 -

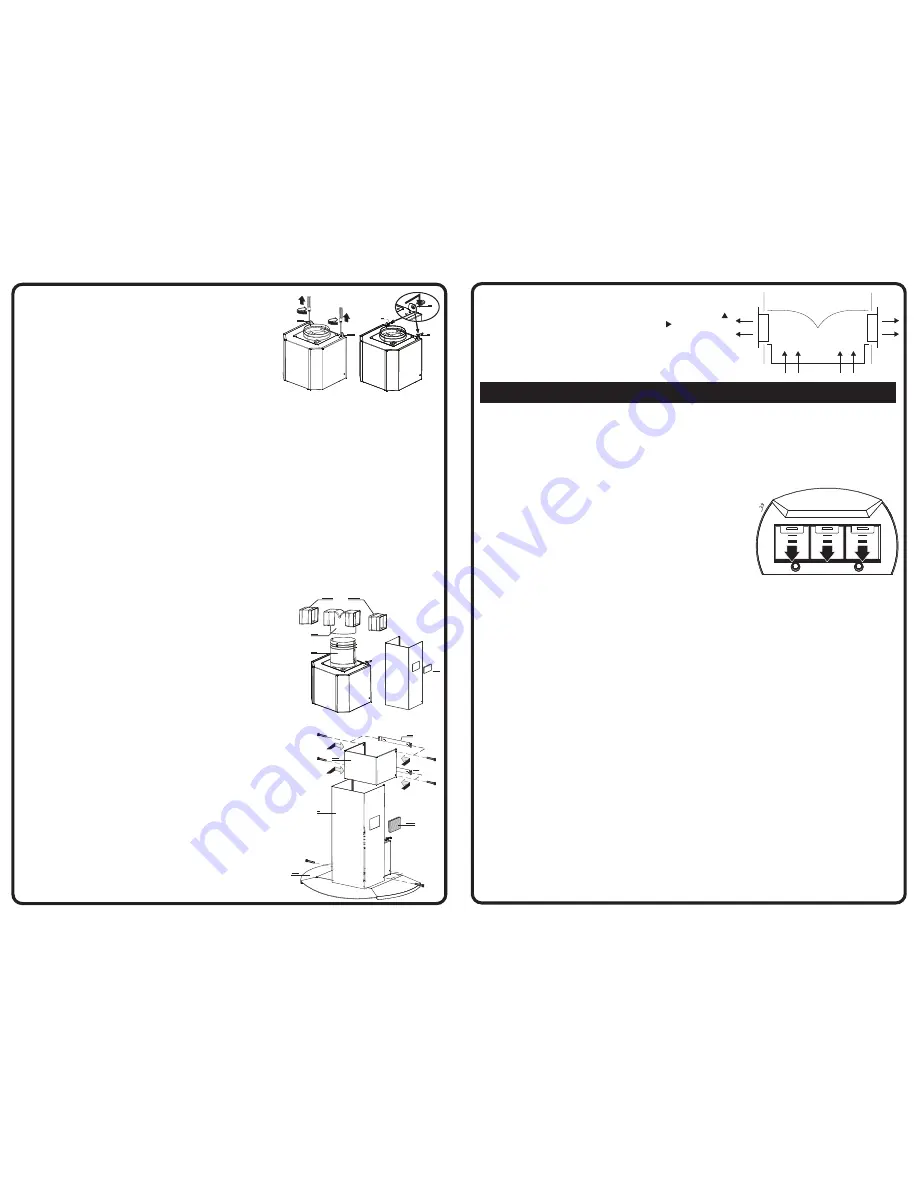

Ducting or Recirculation fitting

Ducting fitting

The hood can be ducted to the outside using either rigid

or flexible ducting Ø150mm .

Recirculation fitting

The filtered air is returned to the room through

the two plastic side grills

G

on the lower

chimney element

I

.

Connect the additional spigot

P

to the round

fan outlet,

pushing it downwards, and fit spigot

R

to additional spigot in a similar manner (make

sure that the two additional side recirculation

spigots

are fitted to spigot

R

). Cut the

additional spigot

P

to correspond with

outlets 1and 2 , which must be formed directly

on the piece. Make sure that the height of the

assembly

R + P corresponds to the height of

the chimney outlet. (fig.7).

Fit the activated charcoal filters inside the

canopy (see paragraph on Maintenance ).

Do not fit the venting grilles until after the chimney

has been installed.

Fitting the telescopic chimney

To fit the upper section

S

first expand the two side

pieces slightly, hook them behind the brackets

2

and

close them

together again until they touch. Fix the

upper section

S

to the brackets

2

using four of

the screws provided in the bag of accessories

(fig. 8).

Fit the lower section I as above, between the

upper section

S

and the canopy

C

using two of

the screws provided in the bag of accessories.

Fig. 8

Fig. 7

R

P1

P1

P

G

G

S

I

2

C

2

Fixing the canopy

Before starting to fix the canopy it will be necessary to

adjust

the support brackets

S1

by turning the

adjustment screws in a clockwise direction until their

reach their limit (Fig.3):

a) Hook the canopy onto the two size

4.2 x 44.4 screws

1

fitted as described

above (Fig.4 ).

b) Level the hood by turning the adjustment

screws and then locking them.

Electrical connection and working test

Before connecting to the mains supply ensure that the

mains voltage corresponds with the voltage on the rating

plate inside the hood.

Connect the canopy hood to the suitable mains connector.

The appliance must be earthed.

Once the electrical connection has been completed, check that

worktop illumination, motor and speed work properly.

Fig. 4

1

1

1

Fig. 3

S1

S1

Constant maintenance guarantees proper operation and long-term reliability.

Particular attention should be paid to the metal grease filters and, for recirculation

hoods only, to the activated charcoal filters. The appliance is equipped with a

system that indicates

automatically when it is time to carry out maintenance

operations.

Metal grease filters

Cleaning

These filters must be washed when LED

Motor

T2

starts to flash,or at least once

every two months,using a normal household

detergent; their compact size also enables

them to be washed in a dishwasher.

Replacement

Remove the filters one at a time, pushing

the handle towards the rear of the hood (fig.

11).

When replacing, ensure that the handle faces

outwards.

Enabling the alarm signal

The hood is already set up to trigger an alarm

indicating saturation of the metal grease

filters,so this function does not need to be

enabled.

Resetting the alarm signal

To turn the alarm signal off,proceed as follows:

Turn off the Lights

T1

and the Suction Motor

T2

;

Press the Speed

T4

and hold for at least

three

seconds, until the Led flashes to confirm.

Note: the saturated filters alarm will only come into

operation when the suction motor is turned on.

WARNING - There could be a possible fire hazard

if the filters are not replaced according to these

instructions.

M A I N T E N A N C E

Fig. 11

Fig. 9

Chimney with venting grilles: Snap the venting

grilles into position in the apertures located

on the chimney section, so that the symbol

is turned upwards and the symbol faces

forwards. Also, when the hood is used in

recirculation mode, ensure that the grilles are

properly secured

to the inside of the recirculation

spigot

R

( fig.9).