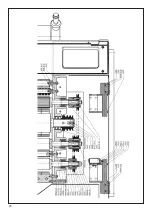

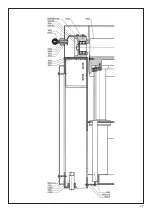

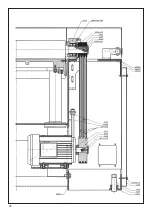

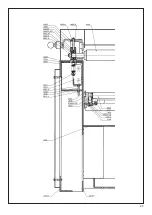

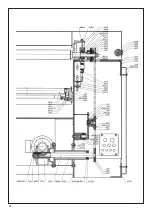

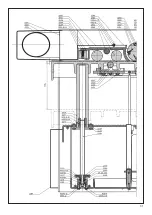

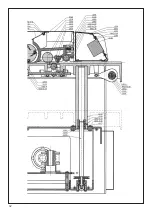

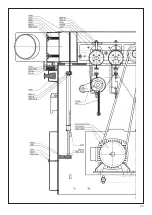

Tensionning the drive chain (fig.10)

The drive chains need no tensionning since the tension is always assured by an idle

chain spanner.

To change the drive chain, pull the chain spanner backwards and remove the chain

from the sprockets and remove the chains.

After the chain is replaced always assure the chain spanner is well placed onto the

chain.

To change the drive chain for the rise and fall of the table, pull the chain spanner lever

to the back and remove the chain.

Attention: do not turn the sprockets on one of the 4 posts of the table whilest

chainging the chain; this will lead into a disorder of the parallelism of the table!

Problems and troubleshooting

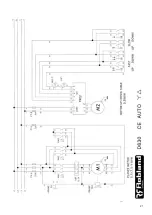

1. The machine does not start when the start button is activated :

- workshop main fuse is switched off: power cut, power shortage, or general overload.

- main switch off: put switch on “1”.

2. Reduction of cutting speed when working :

- belt tension not correct: tension the belt

- motor overload due to incorrect feed rate: reduce the feed rate

- blunt tools: sharpen tools

3. Vibration of the machine :

- worn or damaged belt: replace the belt

- overtensionned belt: loosen belt

4. Thermal overload does not re-arm automatically after shut-off and cooling down

period :

- overload is not set on automatic reset, or the overload is faulty: set on automatic, or

replace

If you cannot solve the problem yourself or you do not find your problem in this list,

please contact your Robland dealer.

Chain spann lever

18

Summary of Contents for D 630

Page 7: ...General dimensions 7 ...

Page 8: ...8 ...

Page 20: ...20 ...

Page 21: ...21 ...

Page 22: ...22 ...

Page 23: ...23 ...

Page 24: ...24 ...

Page 25: ...25 ...

Page 26: ...26 ...

Page 27: ...27 ...

Page 28: ...28 ...

Page 29: ...29 ...

Page 30: ...30 ...

Page 31: ...31 ...

Page 32: ...32 ...

Page 33: ...33 ...

Page 34: ...34 ...

Page 35: ...35 ...

Page 36: ...36 ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 39: ...39 ...

Page 40: ...40 ...