19

Maintenance of the machine

All

maintenance and cleaning work may only be carried out with the main switch set to “O”. The

machine must have been switched off from the mains.

In order to guarantee the life of your machine and also to optimize the quality of your delivered work,

we strongly recommend cleaning the machine once a week and remove all dust and chips that have

accumulated on different parts of the machine.

Especially the carriage must be well maintained. To do this, slide the trolley to the rear and carefully

blow all dust and dirt from between the two profiles and ball cage. Afterwards the steel carriages of the

car must be lubricated with a simple lubricant in spray such as WD40 or other means.

All ball bearings used in the machine are dust-tight and require no lubrication.

Remove any resin deposits on the machine and regularly lubricate the steel axle of the parallel fence.

Caution: when using solvents, be very careful about the risk of fire. !! Do not smoke and keep

the products away from heat sources !!

Problems: causes and solutions

1

The machine does not start when the start button is activated:

-

access door is still open: close the door correctly

-

main fuse is switched off: power cut, power shortage or motor overload

2

Reduction of speed when working:

-

belt tension not correct: tension the belt

-

motor overload due to incorrect feed rate: reduce the feed rate -

blunt

tools: sharpen tools

3

Vibration of the sawblade or spindle:

-

unbalanced tool: replace or have the tool balanced -

worn or damaged belt: replace the belt

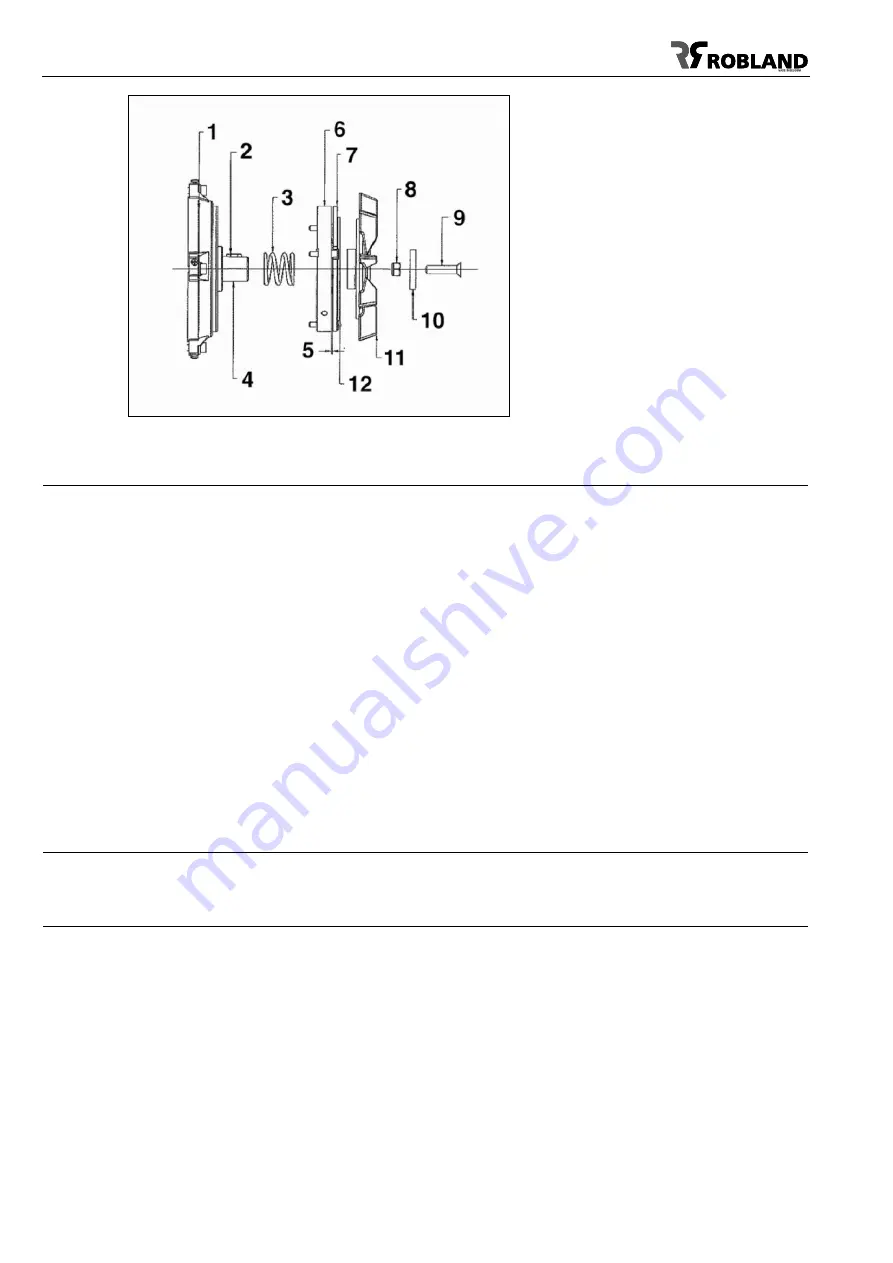

1 Motor frame

2 Key

3 Spring

4 Motor axle

5

Air gap

Electromagnet

6

7 Mobile disk

8 Locking nut

9 Adjustment bolt

10 Washer

11 Braking disk cast iron

12 Brake liner (Ferrodo)

Summary of Contents for M500 EL

Page 6: ...6 General dimensions...