8

Transportation and installation of the

machine

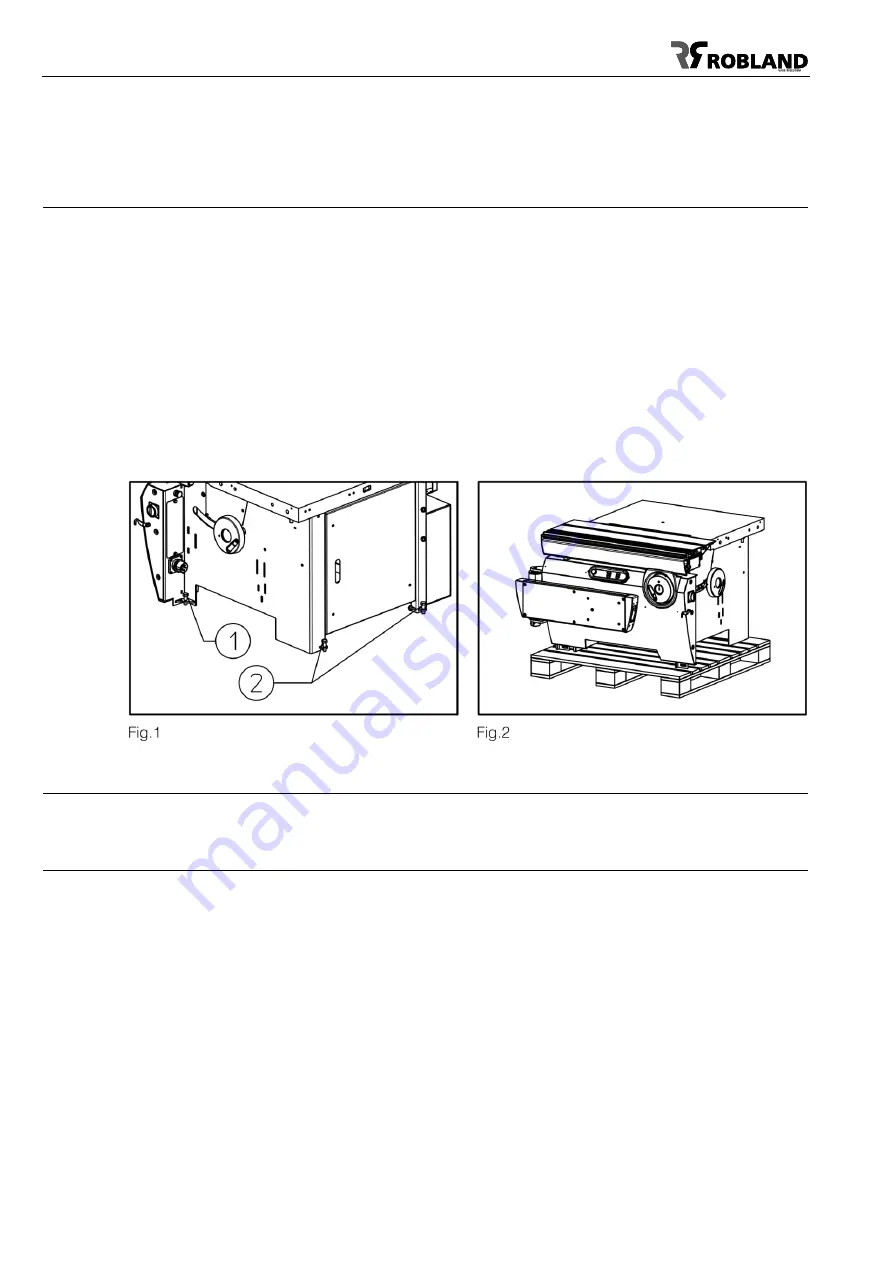

(Fig.1-2)

Depending on the transport or shipping method you will receive the machine either in a box or not

packaged. The packaging itself, made of sturdy fibre boards and the wooden beams, can easily be

reused. You can lift the machine with a crane or forklift truck and bring it to the ground. On the front of

the frame there are two openings with which you can move the machine with a hand pallet truck.

(2) Ensure that the machine is well balanced in the lifting belts when moving. Secure the belts against

lateral shearing.

ATTENTION:

Always check if the payload of your hoist is large enough.

After unpacking, check that the machine has not been damaged during transport or during unloading.

Place the machine stably on a solid surface and provide sufficient space around the machine to work

in a safe manner. The machine must be levelled in both directions. There are 6 adjusting bolts on the

machine, see fig.2

Electrical connection

(Fig.3)

The electrical connection must be carried out by a qualified electrician who is able to calculate exactly

the required wire cross-section and capacity of the workshop fuses.

Check that the main voltage of the machine corresponds with the voltage supply to your workshop.

Now open the electrical switch panel and introduce the cable. Connect the 3 phases to the terminals

on the connection block marked L1, L2, L3. If there is a neutral conductor it must be connected to the

terminal N.

Connect the earth wire (green-yellow) to the terminal marked with the earth symbol PE.

ATTENTION:

-

Check first if the saw spindle runs freely and if all safety devices are fitted before starting the

machine.

-

If the direction of rotation of the sawblade is not correct, the wires L1 and L2 must be exchanged

(clockwise direction of the spindle is correct).

-

For safety reasons this must only be done without the sawblade on the spindle !

Summary of Contents for M500 EL

Page 6: ...6 General dimensions...