–

English

–

Deutsch

14

V1110

NZ3200 - AXIS ERGO

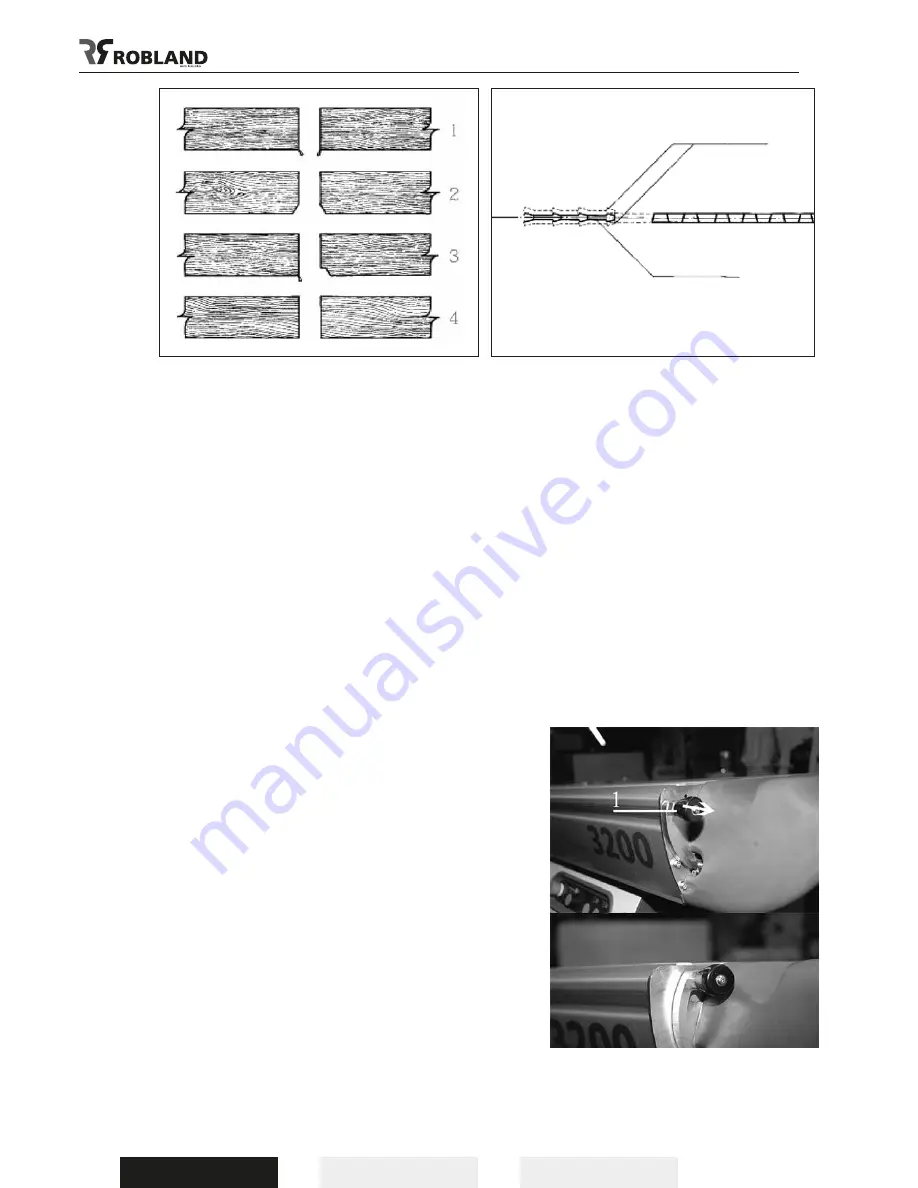

1. The scorer sawblade is below level and does not work properly. There will be chipping on the

interior side.

2. The scorer sawblade is to far up, there will not be chipping but 2 excessive grooves.

3. The scorer sawblade is not aligned properly to the main sawblade. There will be a border on one

side and a waste on the other.

4. Correct setting of the scorer saw

It would be good to fit the height of the blade only at a height necessary for an incision that would

cross exactly the laminated layer or overlay.

In case of extended softwood processing without use of the scorer sawblade, it is recommended to

remove the blade to avoid damage and dust projected by the main sawblade.

Blocking the sliding table (Fig.14)

-

The sliding table can be blocked in two positions and with one block-system. This is vital for

example by loading of the boards or cutting along the parallel guide. The system is located on the

front-side of the sliding table. Pull the button (1) in your direction and turn to the right to liberate the

table. Pull the sliding table till end, the table will be blocked automatically when arriving in the exact

position. Continue this way to start working.

-

When several movements are repeated consecutively,

it is possible that the bearing cage between the two

profiles moves a little bit. We can note this as well by

a reducing travelling distance of the sliding table. To

proceed and achieve the normal travelling distance

of the sliding table, you can adapt the position of the

bearing cage: simply push the table with a few short,

light pushes against the buffer stop at the end of the

sliding table until the position of the ball carrier is

adjusted and the table can be moved again along its full

stroke.

Attention: cleaning and maintenance of the sliding table

It is vital to regularly blow away the saw- and other dust,

collected between the sliding table and the bearing

cage. Push the sliding table to the end, to get a better

reach towards the rails, the bearing cage and gliding

tracks. Oil serves to lubricate the sliding rails and is an

extra guarantee of good use and function.

Fig.14

Fig.15

Fig.16

Not good

Good

Summary of Contents for NZ 3200

Page 1: ...NZ 3200 NZ AXIS ERGO Manual Betriebsanleitung...

Page 3: ...English Deutsch 2 V1110 NZ3200 AXIS ERGO...

Page 32: ...English Deutsch NZ3200 AXIS ERGO V1110 31...

Page 60: ...English Deutsch NZ3200 AXIS ERGO V1110 59...

Page 61: ...English Deutsch 60 V1110 NZ3200 AXIS ERGO...

Page 62: ...English Deutsch NZ3200 AXIS ERGO V1110 61...

Page 63: ...English Deutsch 62 V1110 NZ3200 AXIS ERGO...

Page 64: ...English Deutsch NZ3200 AXIS ERGO V1110 63...

Page 65: ...English Deutsch 64 V1110 NZ3200 AXIS ERGO...

Page 66: ...English Deutsch NZ3200 AXIS ERGO V1110 65...

Page 67: ...English Deutsch 66 V1110 NZ3200 AXIS ERGO...

Page 68: ...English Deutsch NZ3200 AXIS ERGO V1110 67...

Page 69: ...English Deutsch 68 V1110 NZ3200 AXIS ERGO...

Page 70: ...English Deutsch NZ3200 AXIS ERGO V1110 69...

Page 71: ...English Deutsch 70 V1110 NZ3200 AXIS ERGO...

Page 72: ...English Deutsch NZ3200 AXIS ERGO V1110 71...

Page 73: ...English Deutsch 72 V1110 NZ3200 AXIS ERGO...

Page 74: ...English Deutsch NZ3200 AXIS ERGO V1110 73...

Page 75: ...English Deutsch 74 V1110 NZ3200 AXIS ERGO...

Page 76: ...English Deutsch NZ3200 AXIS ERGO V1110 75...

Page 77: ...English Deutsch 76 V1110 NZ3200 AXIS ERGO...

Page 78: ...English Deutsch NZ3200 AXIS ERGO V1110 77...

Page 79: ...English Deutsch 78 V1110 NZ3200 AXIS ERGO...

Page 80: ...English Deutsch NZ3200 AXIS ERGO V1110 79...