–

English

16

Silverline - PS 3200

V0713

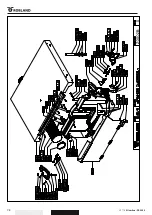

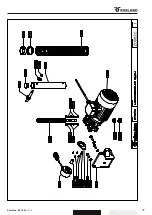

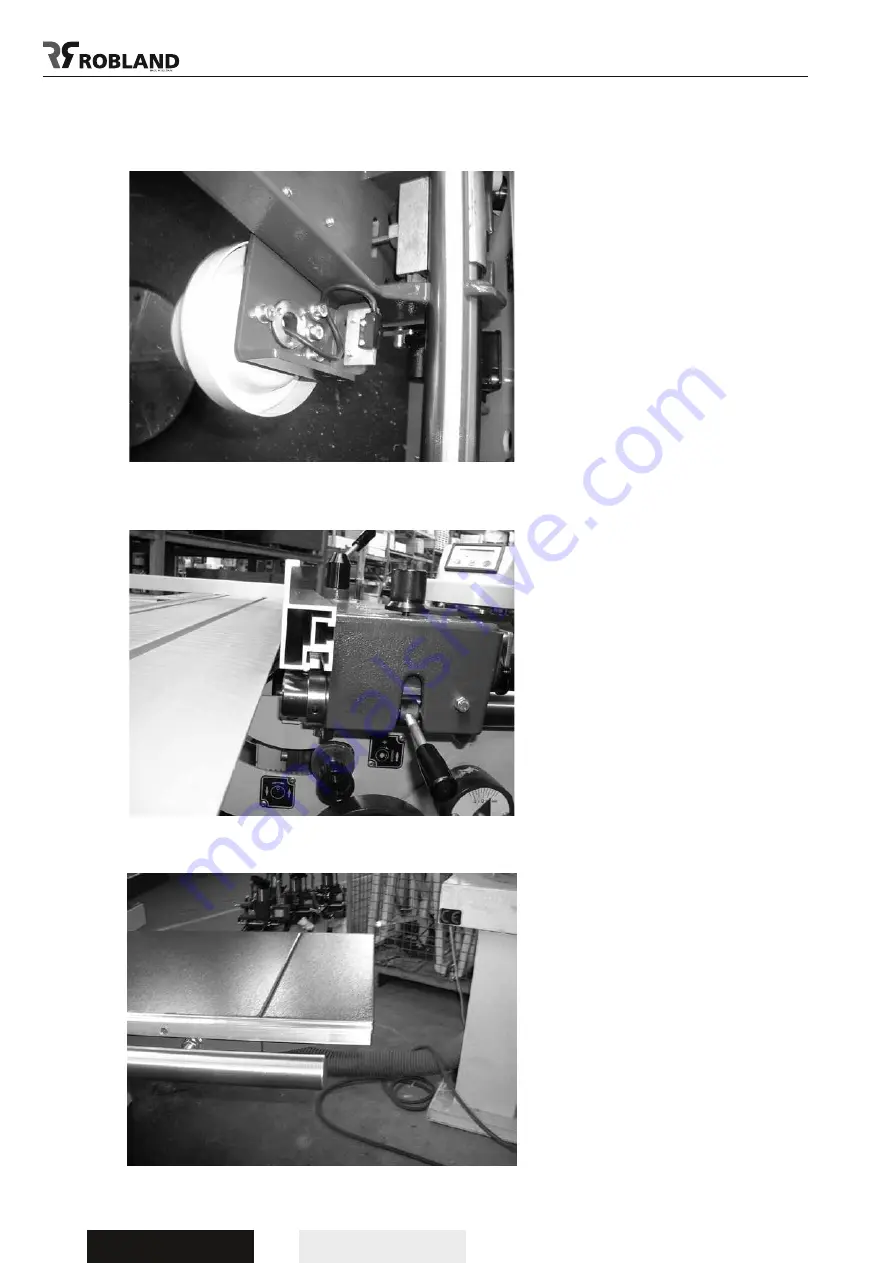

Put the digital read-out onto the parallel fence support block using the 2 holes already

drilled. On older machines these 2 holes need to be drilled.

Now put the alu profile holding the magnetic strip onto the saw table at 1 mm below the table’s front

edge.

Make sure the sensor is put in the middle of the magnetic strip, and the distance between strip and

sensor is set at 0,5 mm maximum.

Make sure the sensor stays at 0,5 mm over the entire lenght of the magnetic strip.

The little table extension as supplied, makes it possible as before to cut upto 1380 mm.

It will also act as a protection for the magnetic tape

.

Summary of Contents for PS 3200

Page 3: ...English 2 Silverline PS 3200 V0713...

Page 26: ...Silverline PS 3200 V0713 25 English...

Page 27: ...26 V0713 Silverline PS 3200 English...

Page 28: ...Silverline PS 3200 V0713 27 English...

Page 29: ...28 V0713 Silverline PS 3200 English...

Page 30: ...Silverline PS 3200 V0713 29 English...

Page 31: ...30 V0713 Silverline PS 3200 English...

Page 32: ...Silverline PS 3200 V0713 31 English...

Page 33: ...32 V0713 Silverline PS 3200 English...

Page 34: ...Silverline PS 3200 V0713 33 English...

Page 35: ...34 V0713 Silverline PS 3200 English...

Page 36: ...Silverline PS 3200 V0713 35 English...

Page 37: ...36 V0713 Silverline PS 3200 English...

Page 38: ...Silverline PS 3200 V0713 37 English...

Page 39: ...38 V0713 Silverline PS 3200 English...

Page 40: ...Silverline PS 3200 V0713 39 English...

Page 41: ...40 V0713 Silverline PS 3200 English...

Page 42: ...Silverline PS 3200 V0713 41 English...

Page 43: ...42 V0713 Silverline PS 3200 English...

Page 44: ...Silverline PS 3200 V0713 43 English...

Page 45: ...44 V0713 Silverline PS 3200 English...

Page 46: ...Silverline PS 3200 V0713 45 English...

Page 47: ...46 V0713 Silverline PS 3200 English...

Page 48: ...Silverline PS 3200 V0713 47 English...

Page 49: ...48 V0713 Silverline PS 3200 English...

Page 50: ...Silverline PS 3200 V0713 49 English...

Page 51: ...50 V0713 Silverline PS 3200 English...