111

FAULT INFORMATION

ENG

8. FAULT INFORMATION

8.1. ALARM MESSAGES

In the event of a breakdown during operation the machine stops automatically and alarm messages appear on the

display.

The table lists the displayed messages, the type of problem, the causes and possible solutions.

Important

For these operations a precise technical expertise or ability is required; therefore, these operations must

be exclusively performed by qualified personnel with certified experience acquired in the specific field of

intervention.

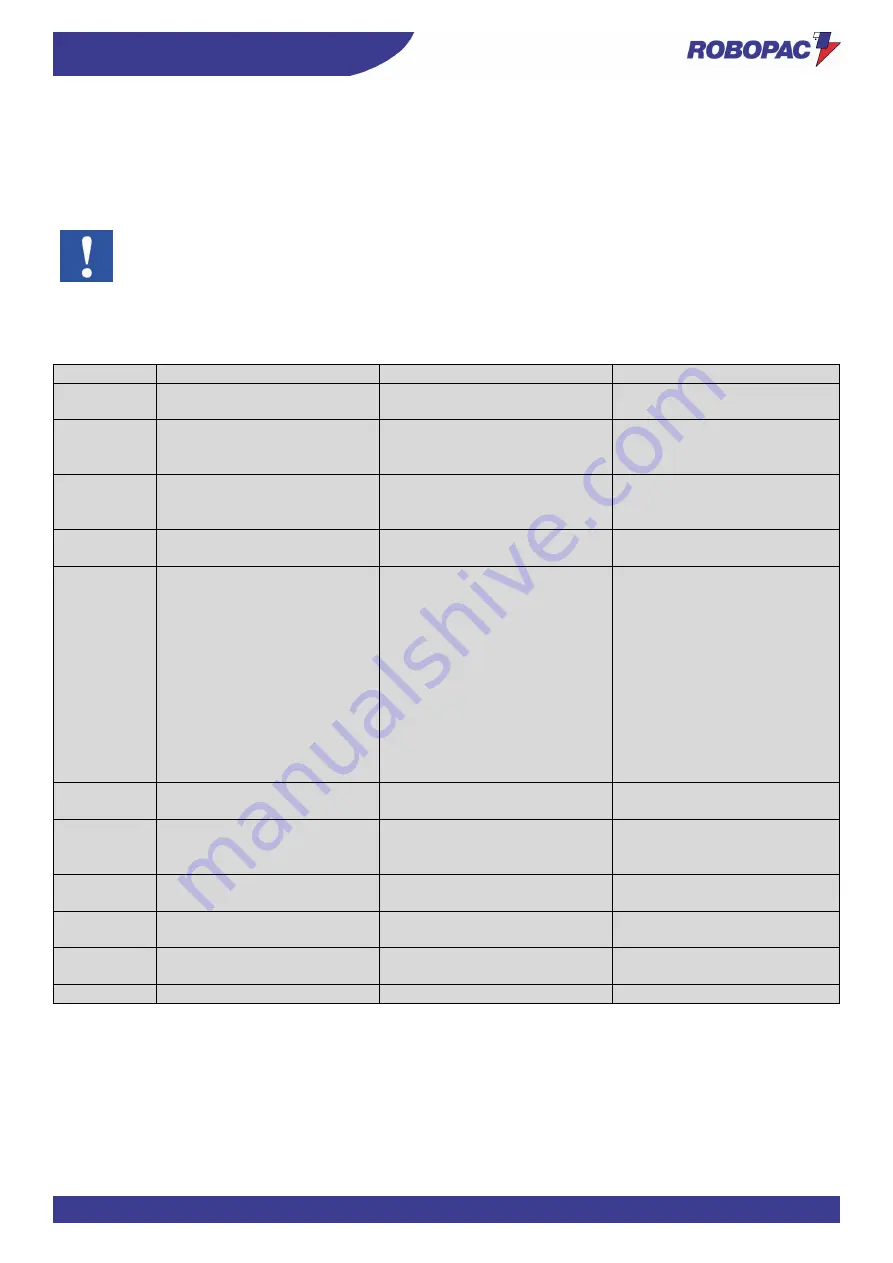

List of alarms

Code

Problem

Cause

Solution

E01

Emergency mushroom-head

button alarm.

Emergency

mushroom-head

button pressed

Reset the button and press the

“Reset” button

E02

Carriage emergency

An obstacle has been detected

along the trajectory during the

spool carriage downstroke.

Remove the obstacle and

press the “Reset” button

E03

Hand pallet truck emergency

An obstacle has been detected

on the pallet loading/unloading

ramp.

Remove the obstacle and

press the “Reset” button

E04

Protection alarm

Intervention of safety barriers or

open door

Remove the obstacle and

press the “Reset” button

E30

Inverter alarm:

1. Table

2. Carriage

3. Stretch

4. Pre-stretch

5. Presser

POWER DRIVER LOW

POWER DRIVER HIGH

OVER VOLTAGE

MAX VOLTAGE

UNDER VOLTAGE

HW POWER CURRENT

OVER HEAT

PHASE FAIL

CURRENT MAX

CURRENT INT MAX

PARAMETER WRONG

COM.ERROR

Contact technical support

E60

“Film breakage” alarm

The film has broken or spool is

finished

Insert the film or replace spool.

E61

Table synchronisation alarm

A fault or an obstacle is

preventing the table from

moving

Solve the fault or remove the

obstacle and press the “Reset”

button

E64

Blocked carriage alarm

The carriage has stopped its

travel

Remove the obstacle and

press the “Reset” button

E65

Blocked presser alarm

The presser has stopped its

travel.

Remove the obstacle and

press the “Reset” button

E71

Presser position alarm

Incorrect presser position

Move the presser down and

start the cycle

E83

MODBUS alarm.

Electronic fault

Contact technical support