- 20 -

Rotoplat DW 108 - 508

14C214003

Rotoplat DW-C 108 - 508

14C214004

English

Chapter 3

TECHNICAL INFORMATION

3.2.

DESCRIPTION OF THE OPERATION CYCLE

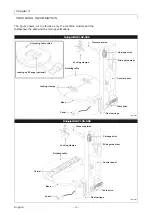

“ROTOPLAT DW 108-508”

‒

Phase 1:

The operator places the load on

the rotating table andclasps the

film in the blocking disk.

‒

Phase 2:

Once the cycle has started, the

turntable starts turning, while the

film carriage unwraps the film

based on the preset parameters.

‒

Phase 3:

Once the wrapping has been

completed, the machine manually

cuts the film and stops.

‒

Phase 4:

The operator supports the product and, with the pedal control,

brings up the presser to unlock from the grippers.

The cycle ends and the machine is ready to start a new one.

3.3.

DESCRIPTION OF THE OPERATION CYCLE

“ROTOPLAT DW-C 108-508”

‒

Phase 1:

The operator positions the

product, having it slide onto the

conveyor and, using the pedal

control, has the presser come

down to lock the top part.

With the pedal control, beside the

carrier (long lever), the operator

locks the lower part of the product.

‒

Phase 2:

Once the cycle has started, the

turntable starts turning, while the

film carriage unwraps the film

based on the preset parameters.

‒

Phase 3:

Once the wrapping has been completed, the machine manually

cuts the film and stops.

‒

Phase 4:

The operator supports the product and, with the pedal control,

brings up the presser to unlock from the grippers.

With the pedal control, beside the carrier (short lever), the operator

unlocks the lower part of the product.

The cycle ends and the machine is ready to start a new one.