SPIROR HP - DR

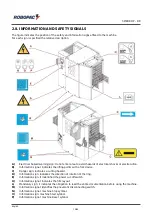

2.6. SAFETY WARNINGS FOR REGULATIONS AND MAINTENANCE

―

Keep the machinery in maximum efficiency condition and perform all the scheduled maintenance

operations provided for by the manufacturer.

Proper maintenance will provide the best performance, a longer life span and constant compliance with

safety requirements.

|

Important

Maintenance work and adjustments shall be carried out by qualified, authorised personnel.

―

Take all necessary precautions (suitably mark the working area and the exits, ensure proper visibility,

provide all necessary supporting equipment, etc.) to ensure safe operation.

―

Delimitate the work area to minimise the risks, as per the workplace safety and health regulations.

―

Enable all machine safety devices before performing any maintenance and regulation operations.

―

Maintenance work in hard to access areas shall be carried out only after having removed any existing

risks.

―

DO NOT use products that contain corrosive, toxic and inflammable substances.

―

Wear the Individual Protection Devices provided by the laws on workplace safety and indicated in the

"Instructions for use" and/or affixed to the machine.

―

Replace the components only with original spare parts or with parts with similar design and functional

characteristics so as to keep the intended safety level unchanged.

―

Use lubricants (oils or grease) recommended by the manufacturer or with similar chemical-physical

features.

―

Do not dump into the environment polluting liquids, worn parts and maintenance waste.

―

Dispose of the same in compliance with current regulations on the matter.

―

Select the components according to the chemical and physical features of the material and carry out

the differentiated waste disposal as per the standards in force.

―

Follow the procedures in this chapter.

―

Non compliance with the instructions given may cause risks for safety and health of the persons and

economic damages.

2.7. SAFETY WARNING FOR ELECTRICAL EQUIPMENT

The electrical system has been designed and built in compliance with applicable legislation.

This legislation also specifies the ambient conditions required for operation.

The following list specifies ambient conditions necessary to ensure correct electrical system function.

―

Ambient temperature must be between

0°C

°C and

40°C

.

―

Relative humidity must be between

50%

(measured at

40°C

) and

90%

(measured at

20°C

).

―

The installation area must not be subject to or contain sources of electromagnetic interference or

radiation (X rays, laser light etc).

―

The installation area must not contain potentially explosive or flammable mixtures of gases or dust.

―

No contaminant or corrosive products (acids, chemicals, salts etc.) may be used during production and

maintenance. Any products used must be kept away from electrical components.

―

The ambient temperature during storage must be between

- 25°C

and

55°C

.

―

Electrical equipment may be exposed to temperatures up

70°C

, provided that exposure does not

exceed

24

hours.

―

The electrical system will function correctly up to an altitude of

1000 m

above sea level.

If any of the aforementioned conditions cannot be met, any additional measures necessary to

ensure safe operating conditions (e.g. special electrical components, air conditioning systems

etc.) must be defined during the contractual stage.

English

12/95

Summary of Contents for SPIROR DR

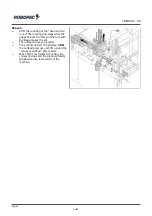

Page 16: ...SPIROR HP DR SPIROR HP SPIROR HP 300 SPIROR HP 400 600 English 16 95 ...

Page 17: ...SPIROR HP DR SPIROR HP 900 SPIROR DR SPIROR DR 400 600 Optional English 17 95 ...

Page 18: ...SPIROR HP DR SPIROR DR 400 600 SPIROR DR 900 Optional SPIROR DR 900 English 18 95 ...

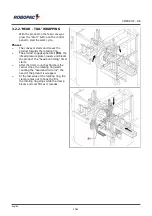

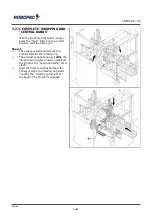

Page 38: ...SPIROR HP DR SPIROR HP 600 SPIROR HP 900 English 38 95 ...

Page 39: ...SPIROR HP DR SPIROR DR 400 SPIROR DR 600 English 39 95 ...