R2N and R2N Ultra

Operation Manual

4

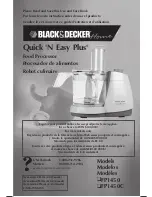

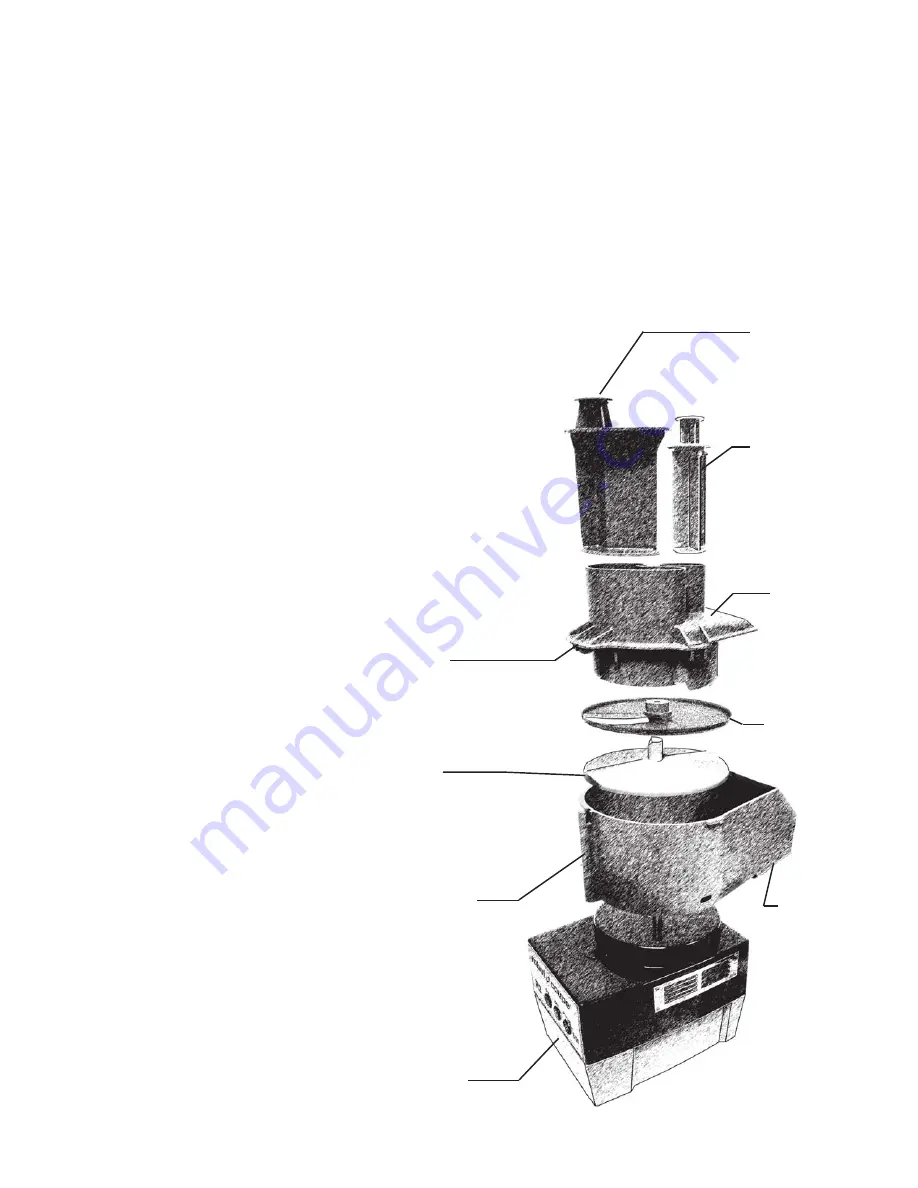

B. CONTINUOUS FEED ATTACHMENT ASSEMBLY INSTRUCTIONS

1. THE CORD SHOULD ALWAYS BE UN-

PLUGGED DURING ASSEMBLY AND DISASSEM-

BLY!

2. Place the continuous feed attachment on the mo-

tor base with the discharge chute to the back (as you

are facing the front of the motor base).

3. Looking from the top, turn the attachment slightly

clockwise, and with a gentle downward pressure, turn

it back counterclockwise; until it locks into place. The

attachment should be level with the top surface of the

motor base.

4. Place the plastic discharge plate on the motor shaft,

and rotate the plate until it drops fully into place on

the motor shaft. When properly installed, it should be

level with and just off the bottom of the continuous

feed attachment.

5. Place the cutting disc of your choice on the dis-

charge plate. Rotate the disc until it drops into place

and is fully seated on the discharge plate.

6. Press the off button in case the ma-

chine was left turned on.

9. DO NOT OPERATE THE MACHINE UN-

LESS IT IS PROPERLY ASSEMBLED AND

THE CONTINUOUS FEED LEAD IS FULLY

SEATED AND CENTERED OVER THE AT-

TACHMENT!

Large

Large

Large

Large

Large

Pusher

Pusher

Pusher

Pusher

Pusher

Motor

Motor

Motor

Motor

Motor

Base

Base

Base

Base

Base

Assembly

Assembly

Assembly

Assembly

Assembly

Exit

Exit

Exit

Exit

Exit

Chute

Chute

Chute

Chute

Chute

Continuous

Continuous

Continuous

Continuous

Continuous

Feed

Feed

Feed

Feed

Feed

Attachment

Attachment

Attachment

Attachment

Attachment

Discharge

Discharge

Discharge

Discharge

Discharge

Plate

Plate

Plate

Plate

Plate

Continuous

Continuous

Continuous

Continuous

Continuous

Feed

Feed

Feed

Feed

Feed

Lead

Lead

Lead

Lead

Lead

Small

Small

Small

Small

Small

Pusher

Pusher

Pusher

Pusher

Pusher

Cutting

Cutting

Cutting

Cutting

Cutting

Plate

Plate

Plate

Plate

Plate

7. Facing the front of the mo-

tor base assembly, place the

continuous feed lead on the

continuous feed attachment

with the ramp on the lead

aligned over the safety switch

rod on the continuous feed at-

tachment. While looking

down at the top, turn the lead

slightly clockwise then back

counterclockwise, locking it in

place. The lead should be

aligned with the top surface of

the continuous feed attach-

ment.

8. Place the pushers in their

corresponding openings in the

continuous feed lead.

Ramp

Ramp

Ramp

Ramp

Ramp