7. Maintenance

The Vacuum Gripper only requires external maintenance with limited downtime.

Maintenance is required after specified usage, measured in cycles (workpiece pick-up and release) or use time (hours).

Following the maintenance interval will ensure :

l

Correct functioning of the Vacuum Gripper.

l

Validity of the warranty.

l

Proper lifetime of the Vacuum Gripper.

Warning

Unless specified, any repairs done on the Vacuum Gripper will be done by Robotiq.

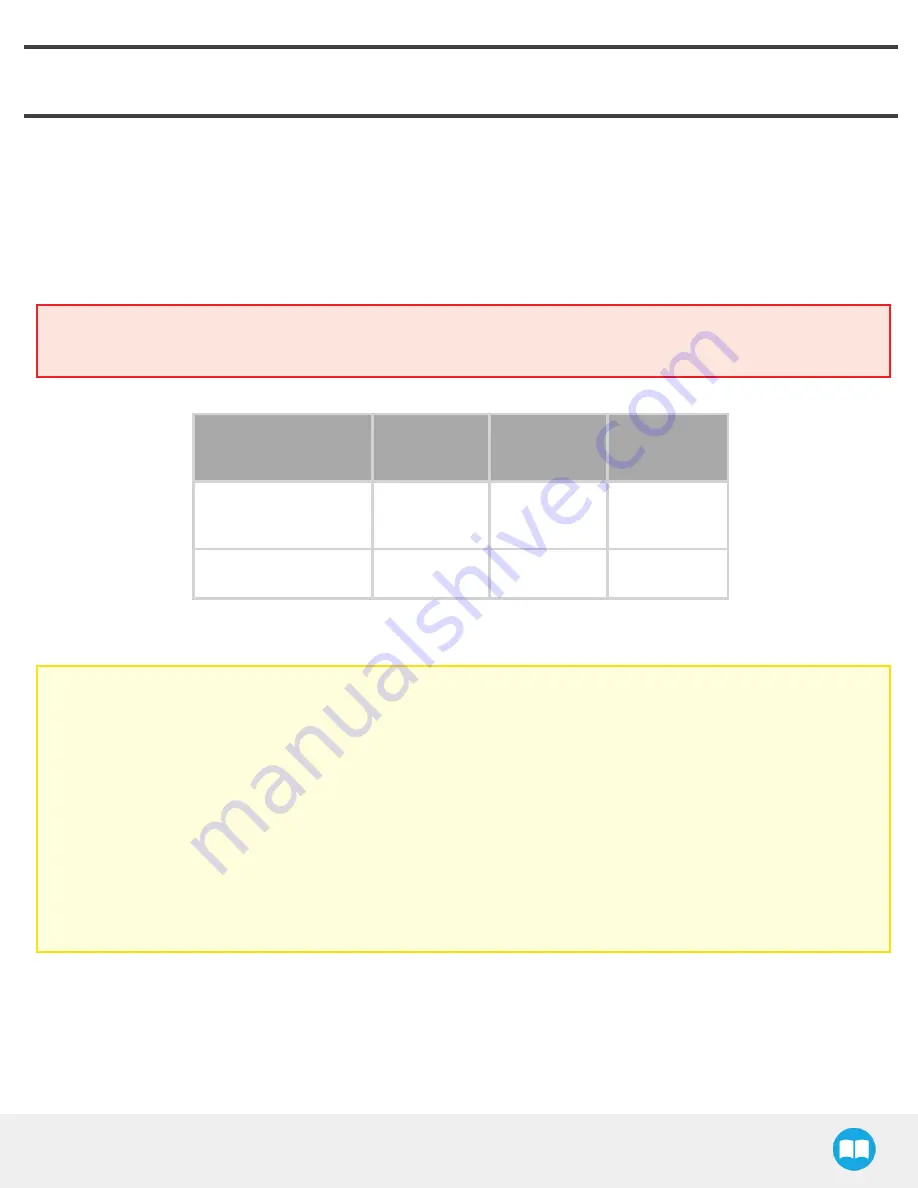

Operation

Daily

Monthly

1 M cycles or

1000 hours

Gripper Cleaning

Dirty

conditions

Normal

conditions

Periodic Inspection

X

Table 7-1: Vacuum Gripper maintenance intervals

Caution

Maintenance operations are for the average normal usage of the Vacuum Gripper, the maintenance intervals must be

adjusted according to the environmental conditions such as:

l

Operating temperature

l

Humidity

l

Presence of chemical(s)

l

Presence of physical objects (debris, scraps, dust, grease etc.)

l

Interaction with operated parts (sharp or rough)

l

Dynamics of the operation (accelerations)

AirPick - Instruction Manual

90

Summary of Contents for AirPick

Page 25: ...Fig 3 7 Mounting air nodes suction cups air bolts air nuts on the bracket 25...

Page 27: ...Fig 3 9 Robotiq Vacuum Gripper with pigtail cable and device cable wiring scheme 27...

Page 35: ...Fig 4 1 Vacuum Gripper control logic overview 35...

Page 57: ...7 Click on the New Project icon in the upper left corner of the screen 57...

Page 58: ...AirPick Instruction Manual 8 Enter a name for your program and click on the OK button 9 58...

Page 76: ...Fig 6 5 Minimum and maximum arrangement possibilities of the air nodes position 76...

Page 77: ...AirPick Instruction Manual 6 1 3 Air nodes Fig 6 6 Air nodes dimensions 77...

Page 103: ...AirPick Instruction Manual 12 Appendix Fig 12 1 Pneumatic schema of the AirPick Vacuum Gripper...