Beginner Level Robot Series

2-2-12.

Cliff Detection Car

Let’s build a car that detects and avoids cliff and obstacle automatically by a sensor.

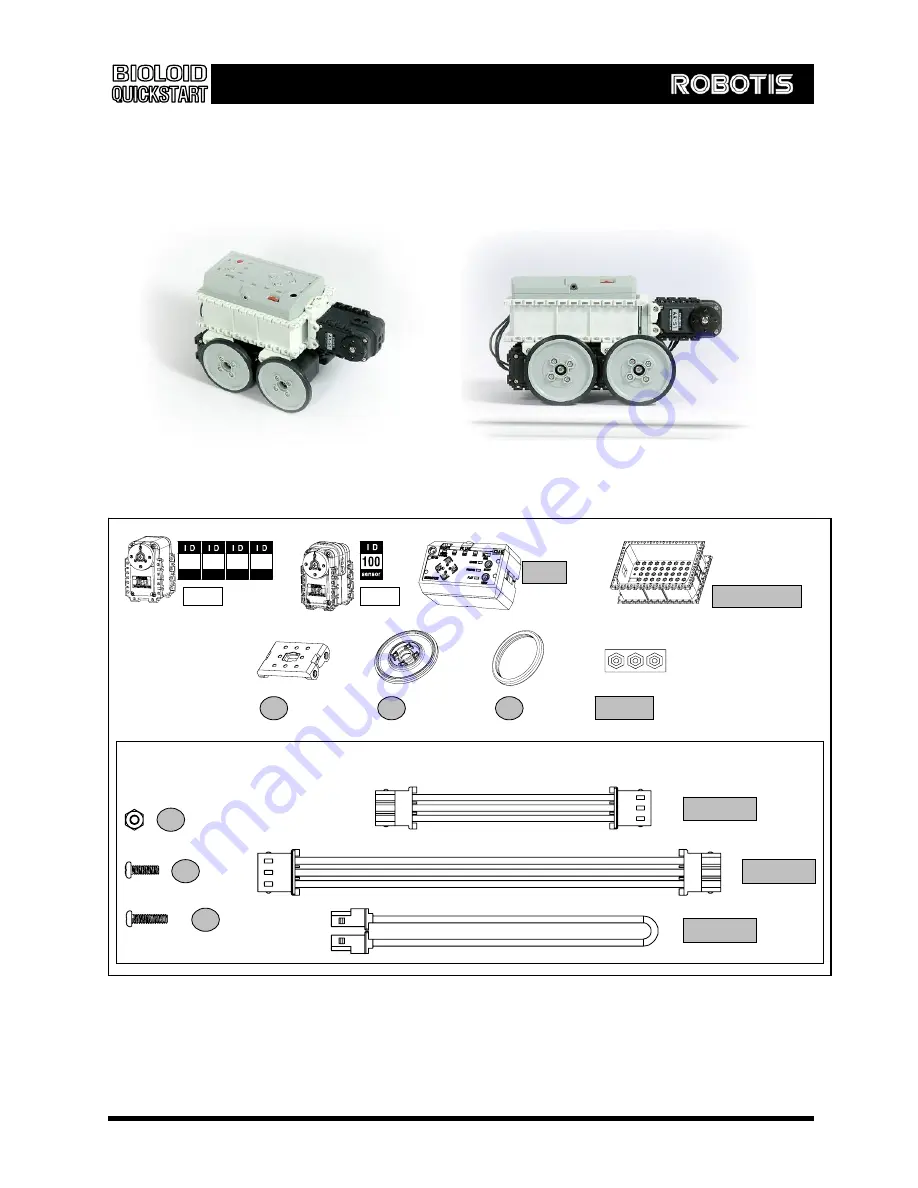

(1) Necessary parts

CM-5

ADAPTOR-CM5

motor

1

AX-12 × 4

motor

2

motor

3

motor

4

AX-S1

F3 × 6

F13 × 4

F14× 4

N1 × 48

S1 × 48

S2 × 16

CABLE-10

CABLE-14

× 2

× 1

Sticker × 10

CABLE-6 × 2

※Nuts, screws, and cables shown below are the same as the actual size. Place and measure the parts

against the below illustration to choose the correct assembly part.

73