16

ISTRUZIONI PER L’USO

I

OPERATION MANUAL AND INSTRUCTIONS

EN

The operating lever is equipped with a release pin which activates in the event of an overload, thus preventing damage to

the accessory due to high forces. Replacement of the release pin is also possible under load and is carried out using an

extraction punch and hammer. Use only original replacement release pins.

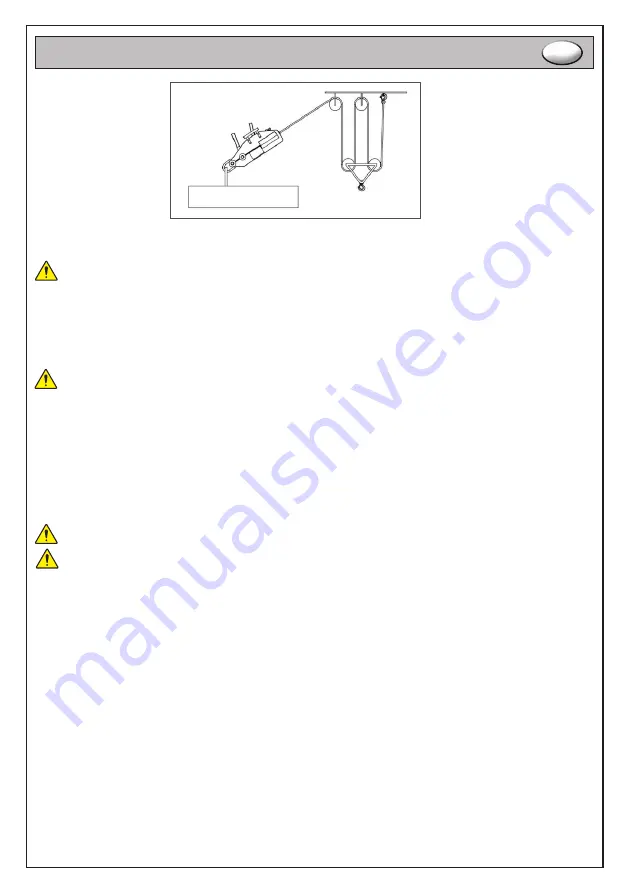

The load capacity can be increased by using deflection pulleys and pulley blocks (Fig. 8) after checking the support structure. The

deflection pulleys and pulley blocks must be dimensioned in accordance with point 5.6 of EN 13157.

Note: The diameter of the deflection rollers must be at least 12 times the nominal rope diameter and the groove depth at least 1.5

times the nominal rope diameter. The deflection roller must be equipped with a rope insertion device that ensures that the rope

remains inside the groove even when it is loose.

Important:

When taking the article out of service, ensure that there are no loads applied and that the rope is released enough to be

removed from the load.

STORAGE

The rope must be removed from the winch and placed on the reel before storage.

The winch should be stored in a dry environment isolated from water. Clean the winch and lubricate the gears using lubricating

oil before storage.

LOADING ROPE

To ensure good condition, when the winch is in use, the load rope should be inspected daily by a competent person.

Use only load ropes of the same diameter as indicated on the winch nameplate and of the stranded, metal core type.

Do not expose the load rope to excessive temperatures, chemicals, abrasive materials and welding arcs.

MAINTENANCE

The winch must be inspected and tested periodically with a load by a competent person, at least once a year and in any case:

- Before commissioning, recommissioning or after substantial modifications

- In accordance with the safety regulations in force in the country of use.

Periodically, especially after heavy or intensive use, it is necessary to lubricate the mechanical components.

The condition and dimensions of the hooks, anchor bolts and rope must be checked regularly. The maximum permissible diameter

reduction on the rope diameter is 10%. The maximum permissible deformations for hook and pin are shown in Figures 9 and 10

respectively.

Fig. 8