Diagnostics

Installation, use and maintenance manual – Caldaia 55.1 and 100.2 Tech

39

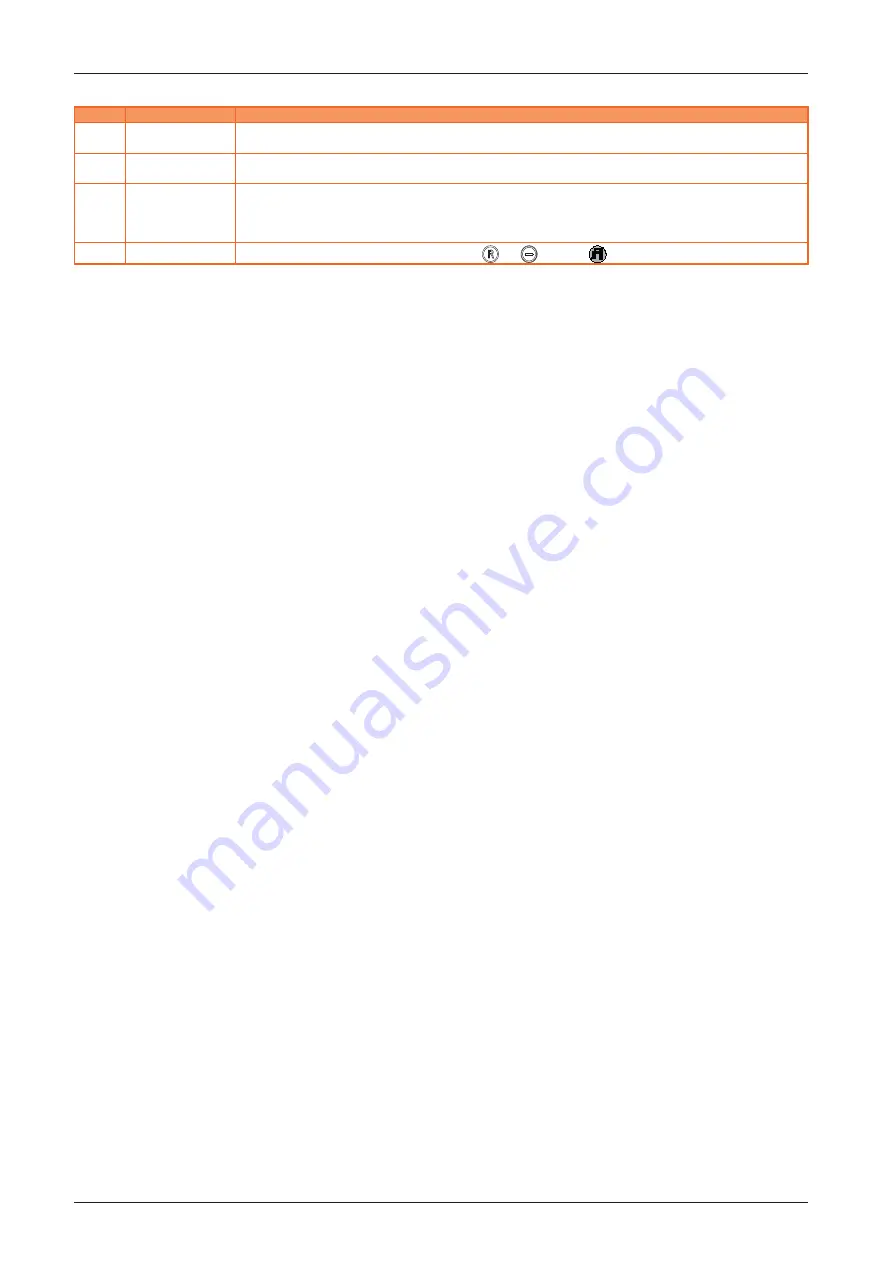

8

Code

Function

Description

F08

Heating antifreeze

function

It is automatically activated when the heating probe detects a temperature of 12 °C. The boiler operates at minimum power and is

deactivated when a temperature of 30 °C is detected.

F09 (1)

DHW antifreeze

function

It is automatically activated when the DHW probe detects a temperature of 4 °C. The boiler operates at minimum power with

diverter valve in summer position. It is deactivated when a temperature of 8 °C is detected.

F33 (2)

System air purge cycle

in progress

It automatically starts when the boiler is first turned on, running for 5 minutes a series of cycles in which the pump is turned on for a

period of 40 seconds and then turned off for a period of 20 seconds. Regular operation is only permitted at the end of the function.

It can also be activated during normal operation of the boiler, in the event that the enable of the water pressure switch is lacking,

when the contact is closed, a 2-minute venting cycle is performed.

FH (1)

Fast H

2

O

It is activated or deactivated by holding down the reset

and

keys of the

DHW side for 7 seconds.

1

Only for boilers with DHW production.

2

Not applicable to 100.2 boilers.