Diagnostics

Installation, use and maintenance manual – Caldaria Con export

51

8

8

DIAGNOSTICS

In the event of a malfunction of the appliance, before contacting

the TAC, make sure that:

▶

There is a full electricity supply.

▶

The gas is supplied.

▶

The gas pressure is within the indicated limits.

▶

The remote control (if any) is set so that the appliance is

switched on and the appliance does not signal a fault.

8.1

SYSTEM PRESSURE RESTORE

In case of malfunction of the appliance, with pressure inside the

hydraulic circuit lower than 0,3 bar, which can be seen through

the pressure gauge located on the instrument panel inside the

boiler, it is necessary, after having identified and solved any leaks

on the circuit, to proceed with the restoring the correct amount

of water (with glycol, if needed), as indicated in Paragraph

3.3

8.2

ERROR CODES

To display the last 5 fault codes, from the most recent in chrono-

logical order, activate the off mode using the

key (Figure

6.1

p. 47) and press and hold the

key for 5 seconds.

▶

To scroll through the list of stored faults, use the

and

keys of the heating side

.

▶

To reset the fault history, press the reset key

.

▶

To exit the display press the

key.

Only for Caldaria 100.2

The fault codes are shown only in the display of the mas-

ter control panel (detail 1 of Figure 5.4

p. 36).

In the event of faults that are not common to both units,

the fault message code is displayed with the prefix 01 or

02, which indicates in which unit the fault is present (01

= master unit, 02 = slave unit).

In the event of failure of both appliances, the display

will show only the most severe code. To display the next

code, press the

key of the DHW circuit

. After re-

solving the most severe code, the display will show the

next code alternating with the collector temperature.

When a fault code represents an anomaly common to

both units (such as E04, E78, E06, E99) it is preceded by

the word E(x), where (x) will be the number of the chron-

ological order in the last 5 reports.

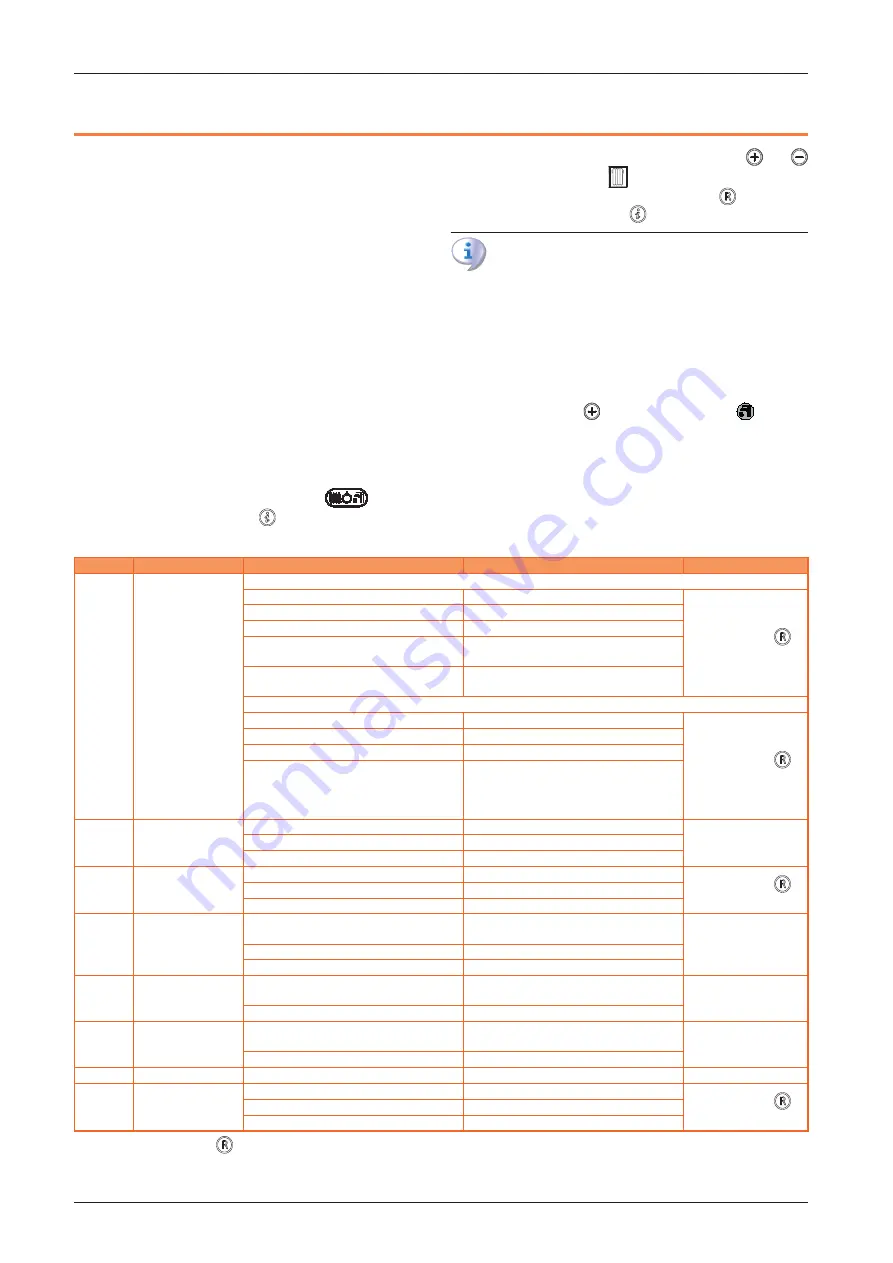

Table 8.1

Error codes

Code

Fault

Possible cause

Remedial action

Reset

E01

Flame lockout

Without flame ignition

No gas supply

Check the gas supply network

Manual reset (press

key) (1)

Broken or badly positioned ignition electrode

Replace

Gas valve fault

Replace

Slow ignition set too low

Adjust the minimum pressure to the burner or

slow ignition

Inlet pressure of gas valve too high (only for LPG

supply)

Check the maximum burner pressure

With flame ignition

Power supply with phase and neutral inverted

Connect the power supply correctly

Manual reset (press

key) (1)

Flame detector fault

Replace

Detection electrode cable disconnected

Check the electrical connection

Phase-to-phase electric current

If the voltage measured between neutral and

earth is almost the same as the one measured

between phase and earth, eliminate the

dispersions

E02

Safety thermostat trip

(95 °C)

Hydraulic circuit overheating

Remove the cause of the lack of heat exchange

Automatic

Thermostat cable broken or disconnected

Check the electrical connection

Thermostat fault

Replace

E03

Flue safety thermal

fuse (102 °C)

Hydraulic circuit overheating

Remove the cause of the lack of heat exchange

Manual reset (press

key) (1)

Thermal fuse fault

Replace

Thermal fuse cable disconnected

Check the electrical connection

E04

Low system water

pressure

Insufficient water pressure in the system (less

than 0,3 bar)

Load the system at the required pressure

Automatic

Water pressure cable disconnected

Check the electrical connection

Water pressure switch fault

Replace

E05

Heating probe fault

Probe fault or out of calibration (nominal resist-

ance 10 KΩ at 25 °C)

Replace

Automatic

Probe connector wet or disconnected

Check the electrical connection

E06 (2)

DHW probe fault

Probe fault or out of calibration (nominal resist-

ance 10 KΩ at 25 °C)

Replace

Automatic

Probe connector wet or disconnected

Check the electrical connection

E10 (3)

False safety trip

Incorrect setting of parameter P32 to value 1

Set parameter P32 to 0

Automatic

E14 (4)

Air pressure switch

Exhaust duct obstructed

Check the flue exhaust duct

Manual reset (press

key) (1)

Pressure switch disconnected

Check the electrical connection

Pressure switch fault

Replace

1

In the Caldaria 100.2 press the

key on the master control panel.

2

Only for boilers with DHW production.

3

Not applicable to Caldaria 100.2.

4

Only for Caldaria 100.2.

Summary of Contents for Caldaria 100.2 Condensing+ export

Page 55: ......