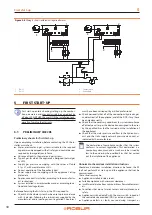

System design

22

3

Electrical and gas continuity

The active antifreeze self-protection is only effective if

the power and gas supplies are assured. Otherwise, anti-

freeze liquid might be required.

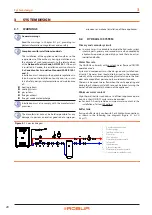

3.6

ANTIFREEZE LIQUID

To ensure the correct operation of the unit and to avoid

water freezing, add antifreeze glycol to the system water

as needed for the minimum external temperature of the

installation zone (Table 3.1

A minimum concentration of 10% by volume of ethylene

glycol (or 15% propylene glycol) is required in all heating

and cooling applications, including warm regions and

even if the water circuit is to be drained during winter

months. This is necessary to protect the unit's heat ex-

changer from freezing during light load operating con-

ditions or off periods. Otherwise, damage to the heat

exchanger will result.

Always use glycol that is permanently inhibited. Do not

use automotive antifreeze.

Precautions with glycol

The manufacturer disclaims any liability for any damage

caused by improper glycol use.

Always check product suitability and its expiry date with

the glycol supplier. Periodically check the product's pres-

ervation state.

Do not use zinc-coated piping and fittings (incompatible

with glycol).

Glycol modifies the physical properties of water (den-

sity, viscosity, specific heat...). Size the piping, circulation

pump and thermal generators accordingly.

With automatic system water filling, a yearly check of the

glycol content is required.

Type of antifreeze glycol

Inhibited type glycol

is recommended to prevent oxidation

phenomena.

Glycol effects

The Table 3.1

p. 22 shows, indicatively, the effects of using a

glycol depending on its %.

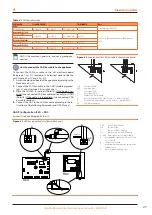

Table 3.1

Technical data for filling the hydraulic circuit

Propylene glycol correction factors

Percent propylene glycol

15%

20%

25%

30%

35%

40%

50%

Approximate freezing point in °F

24

18

15

9

5

-5

-30

Capacity factor multiplier (1)

0.992

0.986

0.972

0.960

0.950

0.928

0.878

Pressure drop multiplier (2)

1.04

1.08

1.13

1.21

1.26

1.47

2.79

Ethylene glycol correction factors

Percent ethylene glycol

10%

15%

20%

25%

30%

35%

40%

Approximate freezing point in °F

25

21

17

11

5

0

-10

Capacity factor multiplier (1)

0.98

0.96

0.95

0.93

0.92

0.91

0.89

Pressure drop multiplier (2)

1.08

1.11

1.16

1.21

1.27

1.32

1.38

1

At standard ARI 590 conditions: 54 °F entering fluid temperature, 44 °F leaving fluid temperature, 95 °F ambient temperature, 0.0005 fouling.

2

Pressure drops may vary with individual glycol manufacturer’s products. The information provided for pressure drop is typical but installing contractor / project engineer is responsible for

verification of pressure drop correction based on specifications of glycol used.

3.7

SYSTEM WATER QUALITY

Responsibility of the user/operator/installer

The installer, operator and user must assure system wa-

ter quality (Table 3.2

p. 22). Failure to comply with the

manufacturer's guidelines may affect operation, integ-

rity and life of the appliance, voiding the warranty.

For any further detail, please contact directly

Robur Corporation Evansville, IN, Phone (812) 424-1800;

Fax (812) 422-5117.

System water characteristics

Free chlorine or water hardness may damage the appliance.

Adhere to the chemical-physical parameters in Table 3.2

and the regulations on water treatment for residential and in-

dustrial heating systems.

Robur is not liable for ensuring that water quality is al-

ways compliant with what reported in Table 3.2

or is not.

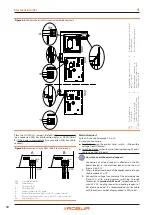

Table 3.2

Chemical and physical parameters of water

Chemical and physical parameters of water in heating/cooling systems

Parameter

Measurement unit

Required value

pH

/

> 7 (1)

Chlorides

ppm

< 125 (2)

Total hardness (CaCO

3

)

°f

< 15

°d

< 8.4

Iron

ppm

< 0.5 (3)

Copper

ppm

< 0.1 (3)

Aluminium

ppm

< 1

Langelier’s index

/

0-0.4

Harmful substances

Free chlorine

ppm

< 0.2 (3)

Fluorides

ppm

< 1

Sulphides

ABSENT

1

With aluminium or light alloys radiators, pH must also be lower than 8 (in compliance

with applicable rules)

2

Value referred to the maximum water temperature of 176 °F

3

In compliance with applicable rules

Water topping up

The chemical-physical properties of the system's water may al-

ter over time, resulting in poor operation or excessive topping

Summary of Contents for GAHP-AR

Page 43: ......