Electrical installer

Installation, use and maintenance manual – GAHP-AR

25

4

Flue gas condensate connection

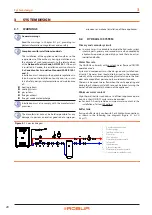

The fitting for flue gas condensate drain is located on the base of

the flue gas exhaust duct (Figure 3.5

▶

The connection of the discharge to the sewerage system

must be made at atmospheric pressure, i.e. by dripping into

a siphoned container connected to the sewerage system.

Flue gas condensate discharge manifold

To make the condensate discharge manifold:

▶

Size the ducts for maximum condensation capacity.

▶

Use plastic materials resistant to acidity pH 3-5.

▶

Provide for min. 1% slope, i.e. 3/8" for each yard of length

(otherwise a booster pump is required).

▶

Prevent freezing.

▶

Dilute, if possible, with domestic waste water (e.g. bath-

rooms, washing machines, dish washers...), basic and neu-

tralising.

3.12

DEFROSTING WATER DRAINAGE

Defrosting

In winter, frost may form on the finned coil and the appli-

ance performs defrosting cycles.

Collection basin and drainage system

▶

Provide for a collection basin or containment rim and a dis-

charge system of the defrosting water, to avoid overflowing,

freezing and damage.

The manufacturer cannot be held responsible for any

damages to persons, animals or goods arising from the

failure to observe this warning.

4

ELECTRICAL INSTALLER

In the following Section please refer to "L" as "L1" and

to "N" as "L2".

4.1

WARNINGS

General warnings

Read the warnings in Chapter III.1

p. 4, providing im-

portant information on regulations and on safety.

Compliance with installation standards

The appliance’s electrical connections and grounding

must be in accordance with the latest edition of the

National Electrical Codes, ANSI/NFPA No. 70 (CSA

Standard C22.1 when installed in Canada)

and with

any local codes. To ensure the electrical safety of this

appliance, it must be correctly connected to an efficient

grounding system. The manufacturer is not responsible

for any damages caused by the failure of the grounding

system.

Installation must comply with applicable regulations in

force, based on the installation Country and site, in mat-

ters of safety, design, implementation and maintenance

of electrical systems.

Installation must also comply with the manufacturer's

provisions.

Live components

After placing the appliance in the final position, and pri-

or to making electrical connections, ensure not to work

on live components.

Grounding

The appliance must be connected to an effective

grounding system, installed in compliance with regula-

tions in force.

It is forbidden to use gas pipes as grounding.

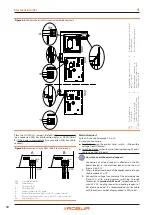

Cable segregation

Keep power cables physically separate from signal ones.

Do not use the power supply switch to turn the ap-

pliance on/off

Never use the external isolation switch (GS) to turn the

appliance on and off, since it may be damaged in the

long run (occasional blackouts are tolerated).

To turn the appliance on and off, exclusively use the suit-

ably provided control device (DDC or external request).

Control of water circulation pump

The water circulation pump of the water/primary circuit

must mandatorily be controlled by the appliance's elec-

tronic board (S61). It is not admissible to start/stop the

circulating pump with no request from the appliance.

Isolation relay

An isolation relay

must

be used to separate the appli-

ance’s transformer from any additional equipment hav-

ing a transformer or damage to the S61 board will occur.

Isolation relays must have a 24 V AC coil, which does not

present more than 0.25 A load to the control circuit.

The manufacturer cannot be held responsible for any

damages to persons, animals or goods due to improper,

erroneous or irrational installation of these appliances.

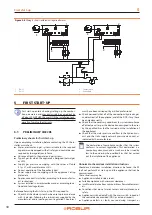

4.2

ELECTRICAL SYSTEMS

Electrical connections must provide:

A.

power supply (Paragraph 4.3

B.

control system (Paragraph 4.4

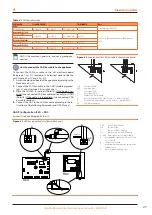

How to make connections

All electrical connections must be performed in the electrical

panel of the appliance:

1.

Ensure the appliance's electrical panel is not live.

Summary of Contents for GAHP-AR

Page 43: ......