Features and technical data

Installation, use and maintenance manual – GAHP-AR

7

1

1

FEATURES AND TECHNICAL DATA

1.1

FEATURES

Operation

Based on the thermodynamic water-ammonia absorption cycle

(H

2

0–NH

3

), the appliance alternatively produces hot water or

chilled water with (seasonal) switching of the hot/cold cycle, us-

ing outdoor air as a renewable energy source and natural gas (or

LPG) as primary energy.

The thermodynamic cycle takes place within a hermetically

sealed circuit, in welded construction, perfectly tight, factory-

tested, which does not require any maintenance or coolant

top-ups.

The cycle of the GAHP-AR is fed by the thermal energy provided

by a gas burner, therefore the required electric energy is limited

to driving the fan and pump motors (the only mechanical mov-

ing parts of the appliance).

The GAHP-AR is fed by natural gas or LPG, and supplied with

208-230 V - 60 Hz single phase electrical power.

The cooling/heating inversion is done by a complex dedicated

valve.

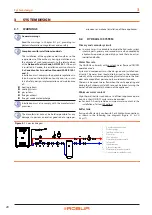

The flue gas exhaust takes place through an appropriate ex-

haust terminal, located on the side of the appliance (Figure

1.1

p. 8), with outlet in a vertical position.

The GAHP-AR unit, for heating and/or cooling systems, is able to

alternatively (not simultaneously) provide:

▶

Hot water up to 140 °F (with a nominal efficiency of 126%).

▶

Chilled water down to 37.4 °F.

1.1.1

Operating mode

Cooling (in summer)

The appliance operates as an absorption chiller and the heat,

taken away from the cooled environment via the hydraulic cir-

cuit, is dissipated towards the outside via the air-cooled finned

coil.

1.1.1.1

Heating (in winter)

The appliance uses the absorption cooling cycle to recover heat

from the outside environment via the finned coil which, added

to the heat produced by the combustion of natural gas/LPG, is

transferred into the exchanger and then into the heated space,

ensuring efficiency of 126% (under nominal conditions, i.e. out-

door temperature 44.6 °F and outlet water temperature 122 °F).

Mechanical and thermo-hydraulic components

▶

Steel sealed circuit, externally treated with epoxy paint.

▶

Multigas pre-mixing burner equipped with ignition and

flame detection managed by an electronic control unit.

▶

Titanium stainless steel shell-and-tube water heat exchang-

er, externally insulated.

▶

Air exchanger with finned coil, with steel pipe and alumin-

ium fins.

▶

Inversion valve on the cooling circuit, for use of the appli-

ance in heating or cooling mode.

▶

Automatic microprocessor-controlled finned coil defrosting

valve.

▶

Variable-flow (for summer operation) microprocessor-con-

trolled helicoidal motor-fan.

Control and safety devices

▶

S61 electronic board with microprocessor, LCD display and

knob.

▶

Auxiliary AR11 electronic board.

▶

Circuit water flow switch.

▶

Generator limit thermostat, with manual reset.

▶

Generator fins temperature probe.

▶

Differential air pressure switch on the combustion circuit.

▶

Sealed circuit safety relief valve.

▶

Bypass valve, between high and low-pressure circuits.

▶

Ionization flame control box.

▶

Dual gas valve.

▶

Antifreeze functions for hydraulic circuit.

Summary of Contents for GAHP-AR

Page 43: ......