Maintenance

36

7

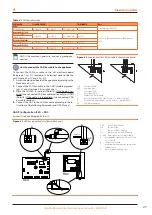

Switch on the appliance using the on/off command (placing it in

the "ON" position).

After switching on with the control, in normal operating condi-

tions, the appliance starts/stops automatically according to the

user's heating/cooling needs, supplying hot or chilled water at

the programmed temperature.

Although the external request is in the "ON" position, this

does not mean the appliance will start immediately, but

it will only start when there are actual service demands.

During operation of the appliance, the summer/winter

switch (from summer to winter operation and vice-versa,

also called "cycle inversion") may require a maximum of

11 minutes from the time this inversion is invoked by the

user.

Switch off

Switch off the appliance using the on/off command (placing it in

the "OFF" position).

The shutdown cycle takes approximately 10 minutes to

complete.

6.3

MODIFYING SETTINGS

Modify settings via the DDC

If the device is connected to the DDC control, refer to the

relevant manual to modify settings.

Do not modify complex settings

Specific technical and system knowledge is required for

complex settings. Contact an AT.

6.4

EFFICIENCY

For increased appliance efficiency:

▶

Keep the finned coil clean.

▶

Set water temperature to the actual system requirement.

▶

Reduce repeated switch-ons to the minimum (low loads).

▶

Program appliance activation for actual periods of use.

▶

Keep water and air filters on plumbing and ventilation sys-

tems clean.

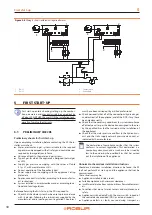

7

MAINTENANCE

7.1

WARNINGS

Correct maintenance prevents problems, assures effi-

ciency and keeps running costs low.

Maintenance operations described herein may exclu-

sively be performed by the AT or skilled maintenance

technician, excluding finned coild cleaning, which can

also be done by the user.

Any operation on internal components may exclusively

be performed by the AT.

Before performing any operation, switch off the appli-

ance by means of the control device (DDC or external

request) and wait for the end of the shutdown cycle,

then disconnect power and gas supply, by acting on the

electrical disconnector and gas valve.

Lubrication of condenser fan, hydraulic pump, and pre-

mixer motor is not recommended.

The efficiency checks and every other "check and main-

tenance operation" must be performed

once a year

.

Responsibility for efficiency checks, to be carried out for

the aims of restricting energy consumption, lies with the

system manager.

Environmental or operational heavy conditions

In environmental or operational conditions particularly

heavy (for example: heavy-duty use of the appliance,

salty environment, etc.), maintenance and cleaning op-

erations must be more frequent.

7.2

SCHEDULED ROUTINE MAINTENANCE

The maintenance operations to be carried out on the appliance,

at least once a year, which can also be done by the user, are:

▶

Clean the finned coil.

The maintenance operations to be carried out on the appliance,

at least once a year, that may exclusively be performed by the AT

or skilled maintenance technician, are:

▶

Check the condenser fan height

▶

Checking that the combustion circuit is fully functional:

inspect and clean flue gas passage

clean the burner

check the ignition and flame sensor electrodes

▶

Check that the oil pump is operating correctly:

check the oil level

replace the belts after 6 years or 12000 hours of opera-

tion

▶

Check the cleanliness of the water filters and efficiency of

the internal flow switch

7.2.1

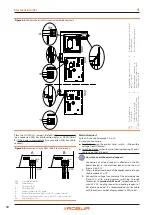

Clean the finned coil

Finned coil cleaning can also be done by the user.

Avoid excessively aggressive cleaning of the finned coil

(e.g. high-pressure washer).

Do not use solvents for cleaning the finned coil. This

could cause damage to the aluminium fins.

Summary of Contents for GAHP-AR

Page 43: ......