37

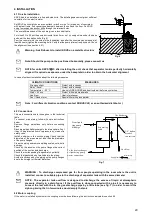

7 TROUBLESHOOTING

Consulting tab.12 and tab.13 can often help to solve troubles or incorrect operation. If the problem persists, please consult us.

Inconveniente

Lista delle cause

The motor does not start and there is no noise

1

The motor does not start but humming noise is heard

2-3-4-5-23

Automatic cut off just after starting

3-6-7-8-9-23

Absorbed power is too high

9-10-11-12-21-22-23

The pump does not produce vacuum

11-13-14-21

The pump produces insufficient vacuum

14-15-16-17-18-19-21-25

The pump makes a strange or loud noise

5-6-9-10-12-20-23

Leakage of liquid from the pump

18-19

The vibrations are too high

5-8-9-10-11-12-20-23-24

Tab 12

Cause

Remedies

1

At least 2 of the electric connections have been cut

off

Check fuses, terminal boards and connection cables and, if

required, replace them

2

At least 1 of the electric connections has been cut off Vedi punto 1 - See point 1

3

The pump is locked

- Clean internal chamber of the pump

- Check clearance of the impeller and, if required, adjust it

4

Faulty impeller

Replace the impeller

5

Faulty bearing

Replace bearing

6

Faulty motor

Check the motor

7

Motor overload

Reduce the service liquid flow rate

8

Too high discharge counter pressure

- Reduce counter pressure

- Check if anything is clogging the discharge piping

9

Too high quantity of liquid entrained with the gas

Reduce the quantity of entrained liquid

10

Scale or other kind of deposits

Decalcify and/or clean the pump

11

Wrong direction of rotation

Change direction of rotation

12

Service liquid flow rate too high

Reduce service liquid flow rate

13

Service liquid is missing

Check the in-feed circuit for service liquid

14

Air leakage in the system

Check pipes seals

15

The pump is too small

Use a larger size pump

16

Insufficient service liquid flow rate

Increase service liquid flow rate

17

Service liquid temperature too high

Cool the service liquid

18

Faulty mechanical seal

Replace the seal

19

Internal erosion/corrosion

Replace damaged components using proper materials

20

Cavitation

- Install VGB valve

- Cool the service liquid

- Increase absolute suction pressure

21

Faulty instruments of measure

Check the instrumentation

22

Stuffing box gland is too tight (only for 30-40 size)

Release pressure exercised by stuffing box gland

23

Ice formation into the pump

Heat the system before starting it

24

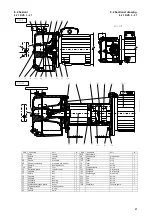

Coupling pump-motor

Check joints, sheaves, V-belts and their alignment

25

Heat exchanger inefficient

Check exchanger tubes fouling, flow rate and coolant

temperature

Tab 13

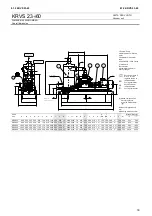

Summary of Contents for KRVS

Page 40: ...40 275974 ...