1

WOODTURNING SAFETY

Failure to follow safety rules may result in serious personal injury.

1.

READ AND UNDERSTAND

the entire owner’s manual before attempting assembly or operation.

2.

READ AND UNDERSTAND

the warnings posted on the machine and in this manual. Failure to

comply with all of these warnings may cause serious injury. Replace the warning labels if they

become obscured or removed.

3.

GET TRAINING:

This Lathe is designed and intended for use by properly trained and experienced

personnel only. If you are not familiar with the proper and safe operation of a Lathe, do not use

until proper training and knowledge have been obtained.

4.

DO NOT USE THIS LATHE FOR OTHER THAN ITS INTENDED USE.

If used for other purposes,

Robust Tools LLC disclaims any real or implied warranty and holds itself harmless from any injury

that may result from that use.

5.

KEEP GUARDS IN PLACE

and in working order.

6.

REMOVE ADJUSTING KEYS AND WRENCHES

. Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before turning it on.

7.

KEEP WORK AREA CLEAN

. Cluttered areas and benches invite accidents. Keep shop floor free of

tripping hazards. Woodturning generates chips and sawdust. Clean up debris and keep your

work area clean. Sawdust is a fire hazard.

8.

DON’T USE IN DANGEROUS ENVIRONMENT

. Don’t use power tools in damp or wet locations, or

expose them to rain. Keep work area well lighted.

9.

KEEP CHILDREN AWAY

. All visitors should be kept a safe distance from work area.

10.

MAKE WORKSHOP KID PROOF

with padlocks, master switches, or by removing starter keys.

11.

DON’T FORCE TOOL

. It will do the job better and safer at the rate for which it was designed.

12.

USE RIGHT TOOL

. Don’t force tool or attachment to do a job for which it was not designed.

13.

USE PROPER EXTENSION CORD

. Make sure your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough to carry the current your product will draw.

An undersized cord will cause a drop in line voltage resulting in loss of power, overheating or

malfunction. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the

cord. See table below:

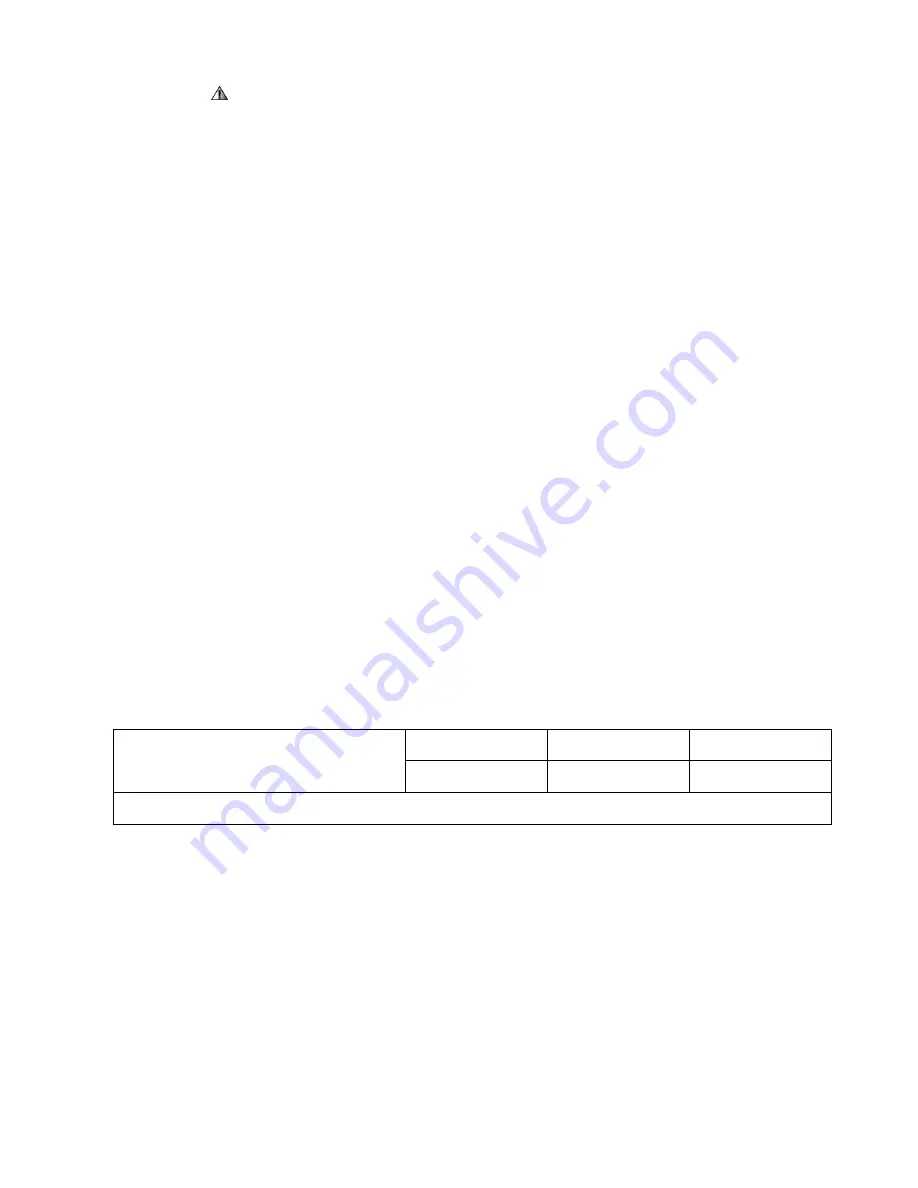

Recommended wire size for

extension cords based on length

25 feet

50 feet

100 feet

14 AWG

14 AWG

12 AWG

NOTE

: Cords longer than 100 feet are not recommended

14.

WEAR PROPER APPAREL

. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts. Nonslip footwear is recommended. Wear

protective hair covering to contain long hair, including beards.

15.

ALWAYS USE SAFETY GLASSES AND FACE SHIELD

. Everyday eyeglasses only have impact resistant

lenses, they are NOT safety glasses.

16.

SECURE WORK

. Use appropriate chucks, faceplates or other work holding devices to hold work

when practical.

17.

DON’T OVERREACH

. Keep proper footing and balance at all times.

18.

MAINTAIN TOOLS WITH CARE

. Keep tools sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

19.

DISCONNECT TOOLS

before servicing; when changing accessories, such as blades, bits, cutters,

and the like.