38

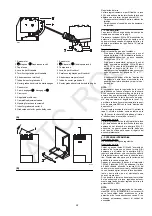

(1) The control box 22)(A)p.6 is fitted with a disc which rotates during the firing programme, which can be seen through the transparent lock-out reset button. When

the burner does not fire or comes to halt following a fault, the symbol which appears behind the reset button indicates the type of problem.

(2) The fuse is located in the rear part of the control box 22)(A)p.6. A pull-out fuse is also available as a spare part which can be fitted after breaking the tag on the

panel which holds it in place.

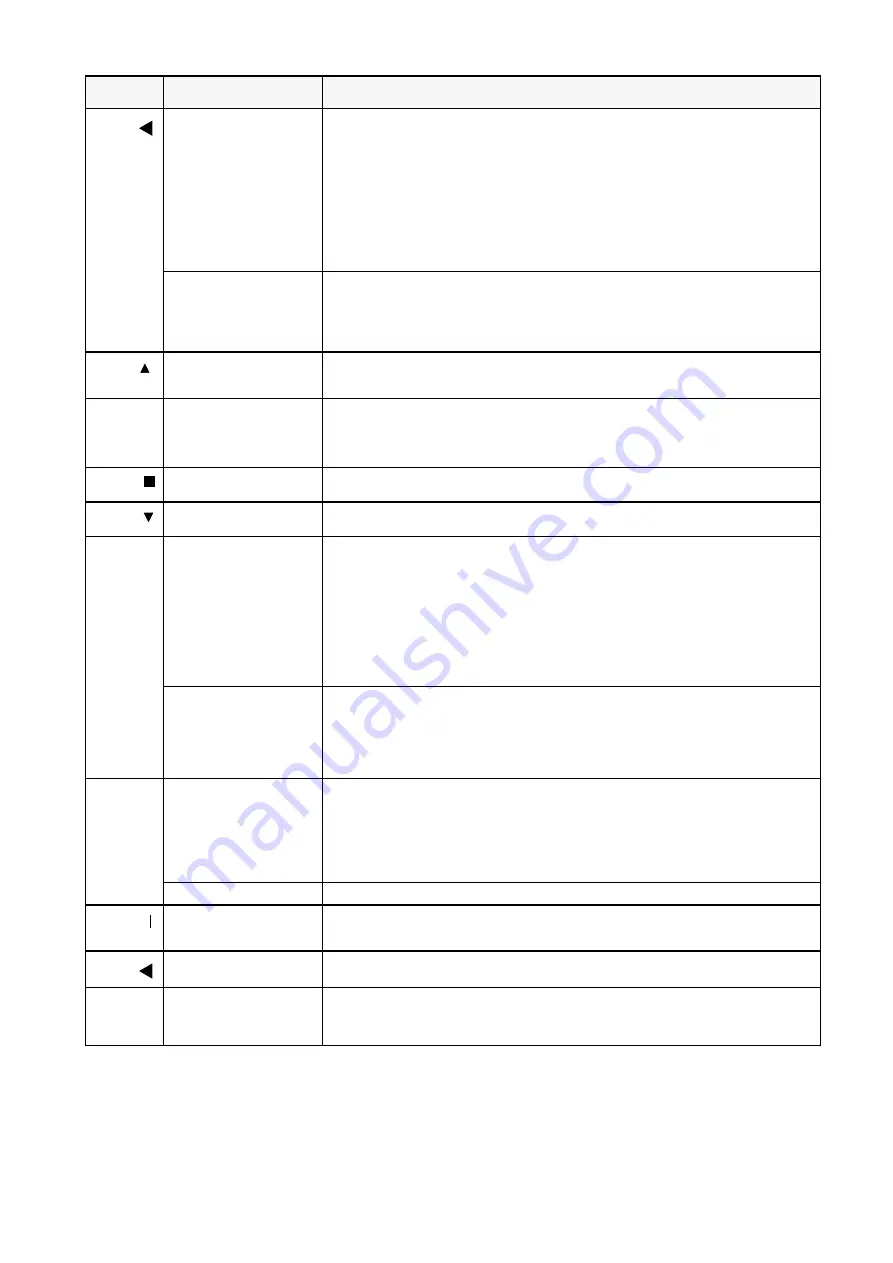

SYMBOL

(1)

FAULT

PROBABLE CAUSE

SUGGESTED REMEDY

The burner does not start

1

- No electrical power supply . . . . . . . . . . . . . . . . . . . . . . . . . Close all switches - Check connections

2

- A limiter or safety control device is open . . . . . . . . . . . . . . . Adjust or replace

3

- Control box lock-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Reset control box

4

- Control box fuses blown . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

(2)

5

- Erroneous electrical connections . . . . . . . . . . . . . . . . . . . . Check connections

6

- Defective control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

7

- No gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Open the manual valves between meter and

train

8

- Mains gas pressure insufficient . . . . . . . . . . . . . . . . . . . . . . Contact your GAS COMPANY

9

- Minimum gas pressure switch fails to close . . . . . . . . . . . . Adjust or replace

10 - Air pressure switch in operating position . . . . . . . . . . . . . . Adjust or replace

11 - Cam I I servomotor contact does not operate . . . . . . . . . . . Adjust cam I I or replace servomotor

control box terminals 11-8

The burner does not start

and a function lock out occurs

12 - Flame simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace control box

13 - Defective capacitor (TECNO 28-GM)

14 - Defective motor remote control switch (TECNO 38/50-GM) Replace

15 - Defective electrical motor . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

16 - Motor protection tripped (TECNO 38/50-GM) . . . . . . . . . . . Reset thermal cut-out when third phase is re-

connected

The burner starts

but stops at maximum

gate valve setting

17 - Cam I servomotor contact does not operate . . . . . . . . . . . . Adjust cam I or replace servomotor

control box terminals 9-8

The burner starts

and then locks out

Air pressure switch inoperative due to

insufficient air pressure:

18 - Air pressure switch adjusted badly . . . . . . . . . . . . . . . . . . . Adjust or replace

19 - Pressure switch pressure point pipe blocked . . . . . . . . . . . Clean

20 - Head wrongly adjusted . . . . . . . . . . . . . . . . . . . . . . . . . . . . Adjust

The burner starts and

then locks out

21 - Fault in flame detection circuit . . . . . . . . . . . . . . . . . . . . . . . Replace control box

The burner stays

in the pre-purge stage

22 - Cam I I I servomotor contact does not operate . . . . . . . . . . Adjust cam I I I or replace servomotor

control box terminals 10-8

After pre-purge and

safety time,

the burner goes to lock-out

and the flame does not appear

23 - The solenoid VR allows little gas through . . . . . . . . . . . . . . Increase

24 - Solenoid valves VR or VS fail to open . . . . . . . . . . . . . . . . . Renew the coil or rectifier panel

25 - Gas pressure too low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Increase pressure at governor

26 - Ignition electrode wrongly adjusted . . . . . . . . . . . . . . . . . . . Adjust, see fig. (C)p.12

27 - Electrode grounded due to broken insulation . . . . . . . . . . . Replace

28 - High voltage cable defective . . . . . . . . . . . . . . . . . . . . . . . . Replace

29 - High voltage cable deformed by high temperature . . . . . . . Replace and protect

30 - Ignition transformer defective . . . . . . . . . . . . . . . . . . . . . . . Replace

31 - Erroneous valve or transformer electrical connections . . . . Repeat connection

32 - Control box defective. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

33 - A cock down-line of the gas train is closed . . . . . . . . . . . . . Open

34 - Air in pipework. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bleed air

The burner goes to lock-out

right after flame appearance

35 - The solenoid VR allows little gas through . . . . . . . . . . . . . . Increase

36 - Ionisation probe wrongly adjusted. . . . . . . . . . . . . . . . . . . . Adjust, see fig. (C)p.12

37 - Faulty electrical connections for probe . . . . . . . . . . . . . . . . Repeat connection

38 - Insufficient ionisation (less than 6 µA). . . . . . . . . . . . . . . . . Check probe position

39 - Probe grounded. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Withdraw or replace cable

40 - Max. gas pressure switch operates . . . . . . . . . . . . . . . . . . . Adjust or replace

41 - Defective control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

The burner repeats

the starting cycle

without lock out

42 - Mains gas pressure is near the value to which the . . . . . . . Reduce operating pressure

min. gas pressure switch gas is adjusted. The

of minimum gas pressure

repeated drop in pressure which follows valve

switch.

opening causes temporary opening of the pressure

Replace gas filter.

switch itself, the valve immediately closes and the

burner comes to a halt. Pressure increases again, the

pressure switch closes again and the firing cycle is

repeated. The sequence repeats endlessly.

Lock out without symbol indication 43 - Flame simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace control box

During operation, the

burner stops in lock out

44 - Probe or ionisation cable grounded . . . . . . . . . . . . . . . . . . Replace worn parts

45 - Fault on air pressure switch. . . . . . . . . . . . . . . . . . . . . . . . . Replace

46 - Max. gas pressure switch operates . . . . . . . . . . . . . . . . . . . Adjust or replace

Lock out when burner stops

47 - Flame remains in combustion head . . . . . . . . . . . . . . . . . . Eliminate persistence of flame

or flame simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . or replace control box

Ignition with pulsation

48 - Poorly adjusted head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Adjust, see page 15

49 - Ignition electrode wrongly adjusted . . . . . . . . . . . . . . . . . . . Adjust, see fig. (C),page 12

50 - Poorly adjusted fan air gate: too much air . . . . . . . . . . . . . . Adjust

51 - Output during ignition phase is too high . . . . . . . . . . . . . . . Reduce

P

1

ATC

ROC

Summary of Contents for TECNO 28-GM

Page 39: ...A T C R O C...