Rockford Systems, LLC

12

Call: 1-800-922-7533

SECTION 2—INSTALLATION

Detect-A-Finger™ Drop Probe Device - Riveter

Other Required Components

(Not part of package unless specifically ordered)

MAIN POWER DISCONNECT SWITCH

A main power disconnect switch may have been supplied in the package shipment. This switch is designed to disconnect the primary voltage to

the machine and lock it out. Please refer to the enclosed wiring schematics for proper wiring of this switch.

OSHA Regulation 1910.217 (b)(8), ANSI Standards B11.1 and B11.3 require that:

“A main power disconnect switch capable of being locked only in the Off position shall be provided with every power press control system.” If the

machine already has a main power disconnect switch, it must be checked for the “locking off” and lockout feature. Some switches use construction

which can be easily altered mechanically to comply with this requirement. If this is not possible, or an electrical disconnect switch is not provided,

then you must obtain and install a proper disconnect switch. (To purchase a disconnect switch, please contact Rockford Systems, LLC)

MOTOR STARTER

A nonreversing motor starter may have been supplied in this shipment. The main purpose of this starter is to drop out the main drive motor and

power to the controls when a power failure occurs. The Detect-A-Finger control must be tied into a motor starter. (For safety reasons do not run a

separate line to the control. Please refer to the enclosed wiring schematics for proper wiring of this starter.)

OSHA Regulation 1910.217 (b)(8) and ANSI Standards B11.1 require that:

“The motor start button shall be protected against accidental operation.”

“All mechanical power press controls shall incorporate a type of drive motor starter that will disconnect the drive motor from the power source in

event of control voltage or power source failure, and require operation of the motor start button to restart the motor when voltage conditions are

restored to normal.”

These requirements are normally met by using a magnetic motor starter. This starter (if furnished) operates with a 120 VAC coil. Refer to the

electrical schematics supplied for details on wiring the starter and associated motor start/stop push buttons.

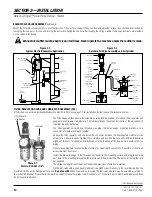

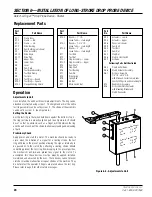

TRANSFORMER PART NO. RSF-021

This externally mounted transformer may have been supplied in this shipment. It has a 100VA, 230/460 volt primary and a 115 volt fused

secondary. The fuse is 1 amp, 250 volt and is accessible from the outside of the transformer housing.

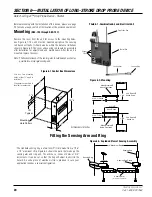

Components Required for Typical Applications

Inspect each machine where these Detect-A-Fingers will be installed. Most machines are controlled electrically, pneumatically or mechanically;

however, other components may be required. Review this section for typical applications of the Detect-A-Finger. Accessory equipment and

components such as solenoid air valves, air cylinders, or electric solenoids are available from Rockford for your convenience. If you require

application assistance for these components, please contact the factory.

All mechanically operated machines that are powered with flywheels, must incorporate single-stroke capability. Please consult factory for single

stroke (single cycle) conversion packages when required.

If single-stroke capability is dependent upon spring action then this feature must be inspected. This spring must be of the compression type,

operating on a rod, or guided in a hole or tube, and designed to prevent interleaving of the spring coils in the event of breakage.

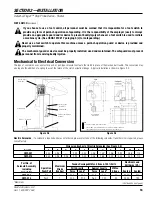

Mechanical to Electro-Pneumatic Conversion

Convert from mechanical operation by removing the hand or foot treadle and replacing it with an air cylinder. The cylinder bore and stroke (push or

pull type) can be determined from actual machine measurements and the location of attachment to the linkage. The air cylinder is controlled by a

three-way, normally closed, 120 VAC solenoid air valve. A filter-regulator-lubricator and pressure gauge assembly is also required. In most cases,

the Detect-A-Finger controls the solenoid air valve.

(Continued on next page.)