Rockford Systems, LLC

14

Call: 1-800-922-7533

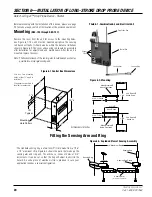

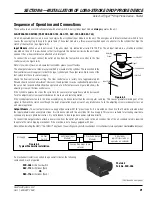

SECTION 2—INSTALLATION

Detect-A-Finger™ Drop Probe Device - Riveter

Yoke Pin

Drive Yoke

Provide loose

ring guide in

either of these

areas if

necessary to

limit cylinder

side-to-side

motion

Flexible Hose

Air Outlet

Port

1

2

Detect-A-Finger

Control Box

Sensing Probe

Electric

Foot Switch

Spring Return

Air Cylinder

(Clutch Actuator)

Solenoid

Operated Air

Valve

Clutch Trip

Rod

Regulated Air

Supply

Power

120VAC

Figure 2.2

Typical Electro-Pneumatic Application

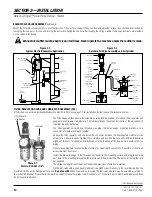

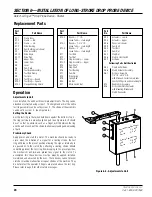

SOLENOID AIR VALVE ASSEMBLY

(continued)

Mount the solenoid valve assembly in a vertical position. The electrical conduit fitting can be easily adjusted to face in any horizontal direction by

loosening the hex nut at the top and turning the enclosure. Retighten this nut after locating the fitting. Saddle clamp-type terminals are provided

on the solenoid for wiring.

Exhaust air muffler must be kept clean at all times. Never operate the machine unless the muffler is clean.

Cylinder

Return

Spring

Yoke Nut

Cylinder

Inlet Port

Electric

Conduit

Fitting

Exhaust Air

Muffler

Exhaust Port

Air Solenoid

Valve

Air

Cylinder

Mounting

Feet

Air Inlet

Port

Solenoid

Mounting

Bracket

Figure 2.3

Solenoid Air Valve Assembly and Air Cylinder

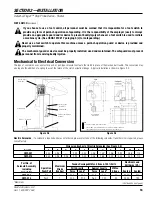

FILTER-REGULATOR-GAUGE AND LUBRICATOR ASSEMBLY (FRL)

(If furnished, see enclosed Installation Manual No. KSL-208. Reference page 15 for installation instructions on the lockout air valve.)

The filter cleans air that goes to the solenoid air valve (and air cylinder, if furnished). The regulator and

gauge are used to adjust air pressure. The lubricator keeps the solenoid air valve or the air cylinder (if

required) properly lubricated.

The filter-regulator unit with one threaded pipe plug, lubricator, gauge, mounting bracket, and a

connector or nipple are shipped together.

Unpack the filter-regulator unit and install the connector between the filter/regulator lubricator (see

arrow for air flow direction). Tighten this assembly and position the two units with both bowls in

alignment. Be sure to check air flow direction and the location of the dual valve to avoid excessive

piping.

Choose an appropriate location on the machine for mounting this assembly. If possible, it should be

accessible from floor level.

Install the pressure gauge in the threaded port opposite the mounting surface and plug the unused

port. Attach the mounting bracket to the machine and then mount the FRL Assembly using the lock

nut supplied.

The air line run length is not critical; but the port and pipe sizes should be maintained.

Fill the lubricator with a good quality lubricant (see OEM’s specifications) to the level indicated by the

maximum fill line on the transparent reservoir.

Do not overfill

. When the machine is cycled, the lubricator drip rate may be adjusted according to

the Instruction Manual. Please check the machine owner’s manual for proper specifications for oil, if required. Some clutch and brake assemblies

do not require lubrication.

Lubricator

Filter/Regulator

Combination

Photo 2.7

Part No. RCL-043 (1/4”)

(Continued on next page.)