TABLE OF CONTENTS

Detect-A-Finger™ Drop Probe Device - Riveter

Rockford Systems, LLC

2

Call: 1-800-922-7533

For maintenance and inspection always refer to the OEM’s (Original Equipment Manufacturer’s) maintenance

manual or owner’s manual. If you do not have an owner’s manual, please contact the original equipment

manufacturer.

Danger is used to indicate the presence of a hazard which WILL cause SEVERE personal

injury if the warning is ignored.

THIS SAFETY ALERT SYMBOL IDENTIFIES IMPORTANT SAFETY MESSAGES IN THIS MANUAL. WHEN YOU

SEE THIS SYMBOL , BE ALERT TO THE POSSIBILITY OF PERSONAL INJURY, AND CAREFULLY READ THE

MESSAGE THAT FOLLOWS.

DANGER

“

”

Safety Precautions

© 2017 Rockford Systems, LLC All rights reserved. Not to be reproduced in whole or in part without written permission. Litho in U.S.A.

SECTION 1—IN GENERAL ........................................................2-7

SECTION 2—INSTALLATION OF CONTROL .............................8-18

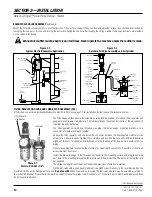

Components in System / General ............................................8

Preliminary Steps Before Installation ................................... 8-9

Specifications and Operating Data ..........................................9

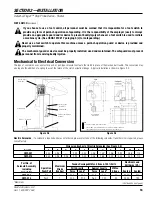

Installation of Components ............................................. 10-17

Other Installation Considerations ..................................... 17-18

SECTION 3—OPERATION .......................................................... 18

SECTION 4—REPLACEMENT PARTS ......................................... 19

SECTION 5—TROUBLESHOOTING ............................................. 19

SECTION 6—LONG-STROKE DEVICE ....................................20-24

LAYOUT OF DETECT-A-FINGER SYSTEM ................................... 25

SECTION 7—ORDER FORM ....................................................... 26

SECTION 8—RETURN AUTHORIZATION FORM .......................... 27

Efficient and safe machine operation depends on the development, implementation and enforcement of a safety program. This program requires,

among other things, the proper selection of point-of-operation guards and safety devices for each particular job or operation, a thorough safety

training program for all machine personnel, that includes instruction on the proper operation of the machine, the point-of-operation guards and

safety devices on the machine, and a regularly scheduled inspection and maintenance program.

Rules and procedures covering each aspect of your safety program should be developed and published both in an operator’s safety manual, as

well as in prominent places throughout the plant and on each machine. Some rules or instructions which must be conveyed to your personnel and

incorporated into your program include:

A company’s safety program must involve everyone in the company, from top management to operators, since only as a group can any operational

problems be identified and resolved. It is everyone’s responsibility to implement and communicate the information and material contained in catalogs

and instruction manuals to all persons involved in machine operation. If a language barrier or insufficient education would prevent a person from

reading and understanding various literature available, it should be translated, read or interpreted to the person, with assurance that it is understood.

Never

place your hands or any part of your body in this machine.

Never

operate this machine without proper eye, face and body protection.

Never

operate this machine unless you are fully trained, instructed, and have read the instruction manual.

Never

operate this machine if it is not working properly—stop operating and advise your supervisor immediately.

Never

use a foot switch to operate this machine unless a point-of-operation guard or device is provided and prop-

erly maintained.

Never

operate this machine unless two-hand trip, two-hand control or presence sensing device is installed at the

proper safety distance. Consult your supervisor should you have any questions regarding the proper safety distance.

Never

tamper with, rewire or bypass any control or component on this machine.

DANGER

DANGER

SECTION 1—IN GENERAL