Rockford Systems, LLC

22

Call: 1-800-922-7533

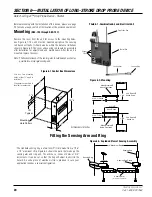

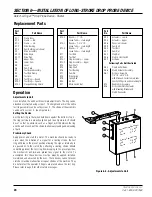

SECTION 6—INSTALLATION OF LONG-STROKE DROP PROBE DEVICE

Detect-A-Finger™ Drop Probe Device - Riveter

ELECTRICALLY-OPERATED DEVICES (PART NOS. RKC-704, RKC-705, RKC-706, AND RKC-707)

On electrically-operated devices, air is still required to operate the air cylinder input module on the unit. On these units, the air cylinder is fitted with

a 115 VAC electric solenoid control valve, which is connected to the electric foot switch. Once this valve energizes the internal mechanism, the

sensing ring drops to its preset point. The output module is an enclosed limit switch with capacity of 15A, 125 VAC suitable for operating a tripping

solenoid or solenoid air valve. (See Figure 6.7.)

Note: Different voltages are available, please consult factory.

Input Module -

To connect the input, attach an air

line (60 to 120 PSI) from the air supply to the flow

control valve on the cylinder. Refer to the air input

instructions, on the previous page, if adjustments

are necessary. Next, connect the foot switch so it

operates the electric solenoid control valve. Please

refer to the wiring diagram in Figure 6.6.

Output Module -

The electric output module is a

limit switch, as described above, which is mounted

on the unit so that it will be actuated when the input

module makes a complete stroke. To connect the

output module, wire the limit switch to operate the

machine control as shown in Figure 6.6.

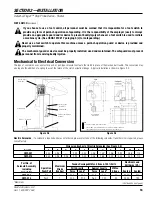

If a mechanical riveter is converted to an electrically-operated riveter, the following components may be required:

CTD-065

Heavy-Duty Electric Foot Switch (See pages 15 - 16.)

OR

CTD-066

Light-Duty Electric Foot Switch (See pages 15 - 16.)

RCL-040

1/4” Filter-Regulator-Lubricator (See pages 14 - 15.)

RCD-006

Solenoid Air Valve Assembly (See pages 13 - 14.)

Air Cylinder

(Push or Pull) (See page 13.)

OR

Electric Solenoid

(Push or Pull) (See pages 16 - 17.)

Note: If different inputs or outputs are required for your application, please consult factory for pricing and part numbers.

Electric Solenoid

(which trips clutch)

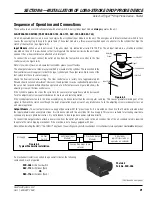

SW-2

L1

L1

1-SOL

To Machine Control

SW-1

GND

115 VAC, 60 HZ

SW-1 = Foot Switch N.O. Contact

SW-2 = Enclosed L.S. N.O. Contact

1-SOL = Solenoid Valve (N.C. Contact)

Figure 6.6 - Basic Wiring Diagram

Air Supply

Air Cylinder (Input

Module)

Electric

Supply

Electric Foot

Switch

Solenoid Control Valve (Input

Module)

Limit Switch

(Output Module)

Solenoid Air

Valve

Air Cylinder

(which trips clutch)

Sensing Ring drops to

preset point

OR

Filter-Regulator-

Lubricator

Figure 6.7

Typical Electrical/Pneumatic Installation

(Continued on next page.)