Rockford Systems, LLC

8

Call: 1-800-922-7533

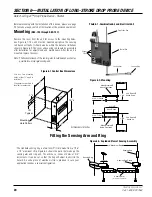

SECTION 2—INSTALLATION

Detect-A-Finger™ Drop Probe Device - Riveter

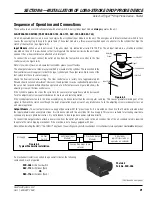

Components in the System

Individual packages may vary in contents. However, a packing list is always enclosed showing exactly what material was shipped on this order.

Please check the components actually received against this packing list. Standard components of this system are as follows:

q

Literature Folder

q

Control Box (Right or Left Mount)

q

Sensing Probe (2) (formed by user) and Sensing Probe Clamp

(Sensing probe on the long-stroke devices (see pages 20-23) is formed as illustrated.)

Other components that may be required for a particular application are:

q

Disconnect Switch

q

Motor Starter

q

Transformer

q

Air Cylinder Assembly

q

Solenoid Air Valve or Electric Solenoid (Pull Type)

q

Air Filter-Regulator-Gauge and Lubricator Assembly

q

Lockout Valve

q

Foot Switch

General Information

The purpose of the Detect-A-Finger Drop Probe Device is to effectively reduce accidents on applications where the operator’s fingers may enter

the point of operation. The components of this system are (1) a “Mechanical Sensing Probe” shaped to fit over or around the workpiece and (2) a

Control Box. When the operator initiates a machine cycle, the “Sensing Probe” is released and drops by gravity over or around the workpiece. If

the operator’s fingers are still in the danger area, the “Sensing Probe” cannot reach its preset down position and the machine is prevented from

cycling. Conversely, if no obstruction prevents the “Sensing Probe” from dropping, then as soon as it reaches its preset down position, the control

unit will allow the machine to cycle.

The control box is ruggedly built to provide continued successful operation under operating conditions usually found around this type of machinery.

The sensing probe that operates the limit switch is tied into the control relay (in the control box) and when properly wired into the machine system

prevents cycling of the machine accidentally or intentionally. This can be confirmed by moving the “Sensing Probe” manually without operating the

hand or foot actuating means.

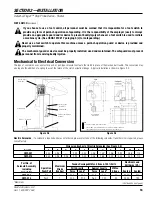

Preliminary Steps Before Installation

Before proceeding with the installation of the enclosed equipment, the following preliminary steps should be considered:

1.

Read and make sure you understand this entire Installation Manual.

2. Ensure that the machine is in first-class condition.

Before starting any installation it is essential that the machine be thoroughly inspected.

Make sure all mechanical components and collateral equipment are in first-class operating condition. Your inspection should be in accordance

with the machine manufacturer’s installation and maintenance instruction manual. If you have any doubts or questions concerning the condition

of the machine, contact the machine manufacturer for assistance.

Repair or replace all parts not operating properly before proceeding.

Inspection and maintenance programs must be established and implemented to keep machines in

first-class condition. Programs must include thorough inspections of each machine on a weekly

basis and records kept of these inspections. Any part of the machine that is worn, damaged or is not

operating properly must immediately be replaced or repaired before the machine is used.

3.

Verify that the machine is in first-class condition and operating properly. Shut off all power to the machine. Padlock the disconnecting means

in the “off” position and do not actuate the machine again until the installation of all package components has been completed. Lockout/tagout

energy isolation procedures must also be practiced and enforced for all energy sources when installing the enclosed equipment, setting up and

maintaining the machine.

(Continued on next page.)