Rockford Systems, LLC

Call: 1-800-922-7533

9

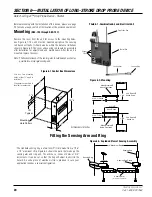

SECTION 2—INSTALLATION

Detect-A-Finger™ Drop Probe Device - Riveter

Preliminary Steps Before Installation

(continued)

The operator must be protected from all hazards. All applicable sections of OSHA Section 1910.212, General Machine

Safeguarding, and ANSI B154.1 for Rivet Setting Equipment, must be complied with on all machines where this equipment

is installed.

The Detect-A-Finger controls are applicable on most types of riveting, eyeletting, staking and similarly operated assembly

and fastening machines. The function of the Detect-A-Finger device, when properly installed, adjusted and maintained,

is to keep the operator from inadvertently cycling the machine with fingers in the point of operation. The Detect-A-Finger

control does not incorporate single stroke capability. This control only provides an interface between the clutch actuator

and the trip control operating means which will not allow stroke initiation unless the area being probed is cleared of all

unwanted obstructions. To accomplish this protection, the Detect-A-Finger must be properly installed on the machine and

the device must be properly maintained and adjusted by the user. A properly designed sensing probe must be used and

additional sensing probe safeguarding must be provided where applicable. This device does not protect the operator if

fingers are placed above the sensing probe. This device cannot prevent clutch or machine malfunction or repeat strokes

of the machine.

Before starting any installation work, it is imperative that the machine’s clutch is inspected and exhibits proper operation.

Run the machine in a normal operating sequence to determine proper operation. Do not install the Detect-A-Finger on

a machine that does not function properly. When the machine is operating satisfactorily, shut off the power with the

disconnect switch and do not operate the machine again until installation is complete. Use of a lockout device and padlock

on the disconnect handle must be used during this period.

The maintenance and inspection section in this manual cannot be all-inclusive for maintaining machines. Always refer

to the original machine manufacturer’s maintenance manuals or owner’s manual. If you do not have an owner’s manual,

please contact the original equipment manufacturer.

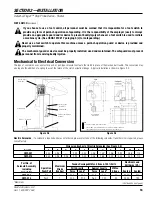

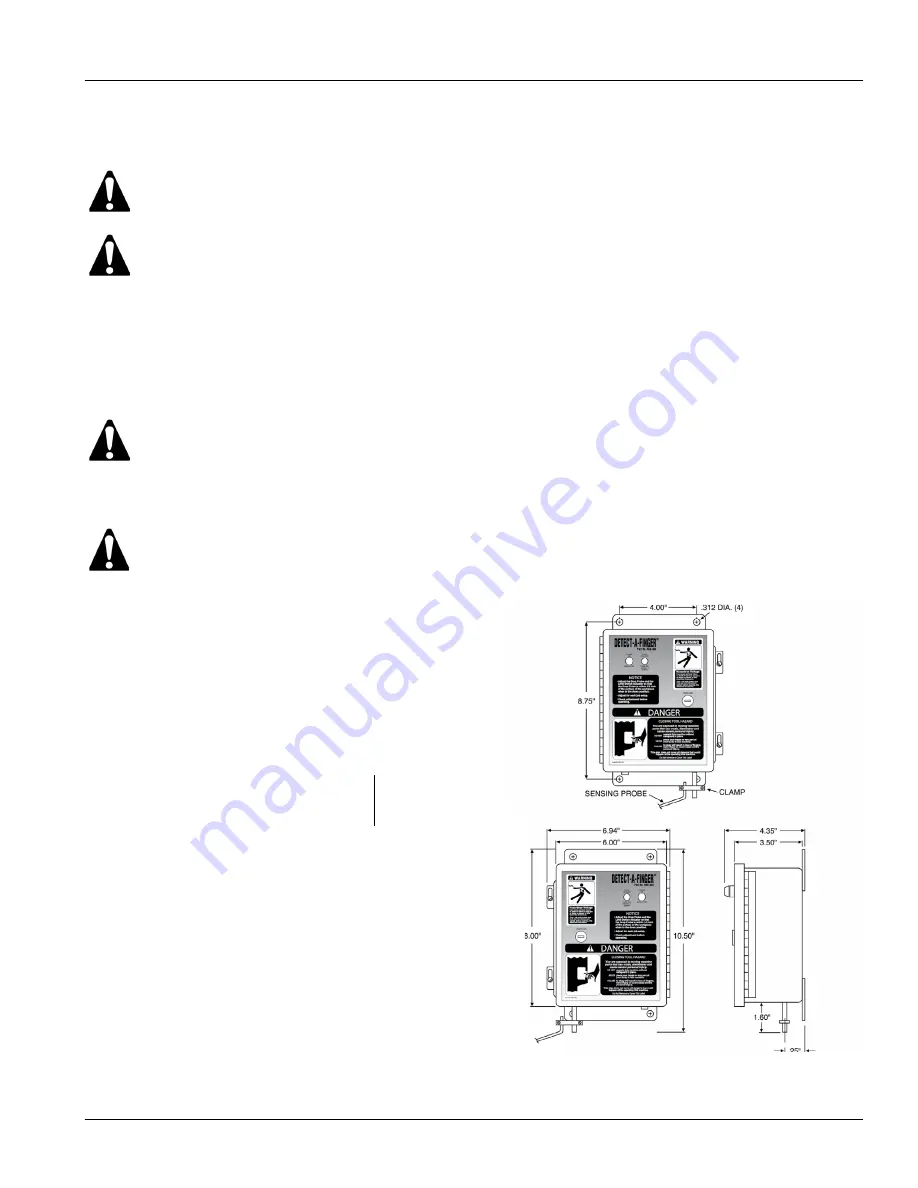

Specifications and Operating Data

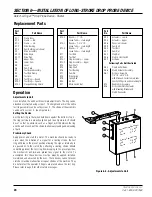

CONTROL BOX

Part Number

..................................................RKC-000 or RKC-001

Fuse

.............................................................................. 313 Series,

3AG, 3 Amps, ..................................................................................

.............................................................................. 250V, Slow Blow

Input Voltage

....................................... 115 + 15% VAC, 50/60 Hz

Operating Current

............................................... 0.8 Amps Typical

Output Relay Ratings

Resistive

General Use

10A 110VAC 7.5A 110VAC

7.5A 220VAC 5A 220VAC

10A 30VDC

Operating Current

............................................... 3.0 Amps Typical

Duty Cycle

.............................................25% (10 Second Maximum

........................................................................Continuous On-Time)

Stroke

.........................Travel Adjustable to 1.75 (1-3/4) Inches Max.

Mechanical Life

................................. Relay - 10 Million Operations

........................................... Rotary Solenoid - 100 Million Operations

Weight

...............................................................................3.5 Lbs.

SENSING PROBE (UNFORMED)

Part Number

..................................................................... FCT-030

Wire Size

................................................156 Dia. x 18 inches Long

Materia

.................................................... Aluminum Rod (Standard)

Total Weight

........................................ (Including Probe and Clamp)

............................................................. 0.5 lbs. Maximum Allowable

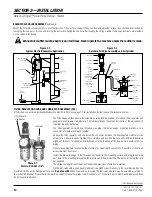

Left Side Mount

Control Box

(Part No. RKC-001)

Right Side Mount Control Box

(Part

No. RKC-000)