2

This manual outlines two specific types of enclosures that provide

distinctly different performance.This section is to help you decide

which type is best for your application.

SEALED ENCLOSURES

Sealed enclosures are the simplest to build.The most important part of

building a sealed enclosure is to make sure that the enclosure is airtight.

Using glue and some type of sealant on all seams will ensure solid

construction and prevent air leaks.The box volume will directly impact

the performance of the speaker. Larger enclosures will provide flatter

response and deeper bass where smaller boxes will provide a bump in

the response curve and generally higher output for greater SPL.

Advantages of sealed enclosures:

•

Small enclosures

•

Linear (Flat) response

•

No port noise

•

High power handling at all frequencies

•

Excellent for sound quality

•

Extended low frequency output when compared to vented enclosures

VENTED ENCLOSURES

Vented enclosures vary only from the sealed enclosure in that a vent or

port is added to “tune” the enclosure.The enclosures recommended are

designed for great overall performance. Larger boxes tend to be easy to

tune to lower frequencies while medium and small boxes are easier

to tune to higher frequencies.The vented design is less linear in

response than the sealed box but with noticeably more output at

the tuning frequency.

Advantages of vented enclosures:

•

Higher average output than sealed

•

Tuning frequency can be easily adjusted by changing port length

•

Deep bass response with lower power requirements

•

Great for high output with limited power

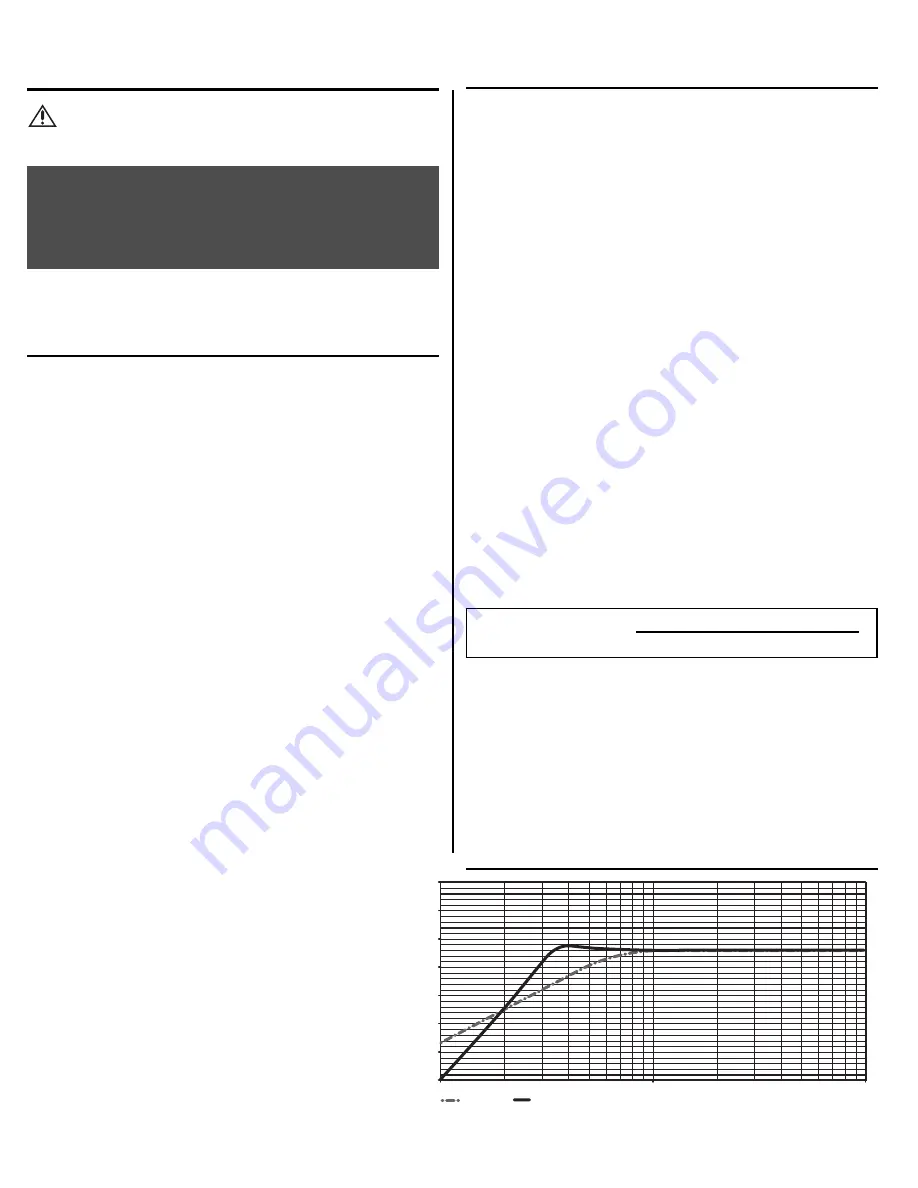

The graph shown here is a sample of how the F3 drop-off

point differs between sealed and vented enclosures.

BUILDING AN ENCLOSURE

To work properly, the walls of the enclosure must be rigid and not flex

when subjected to the high pressures generated by the speaker's

operation. For optimum performance, we recommend using 3/4" MDF

(Medium Density Fiberboard) and internal bracing.The enclosure should

be glued together and secured with nails or screws.

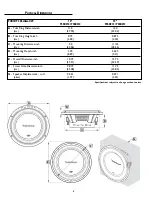

CALCULATING VOLUME

Calculating volume is merely a matter of measuring the dimensions in

inches and using the formula: H x W x D divided by 1728 (cubic feet).

See block below.

If two facing sides are of uneven length, add them together and divide by

two to take the average. Using this number will give you the volume

without the necessity of calculating the box in sections and adding the

sections together.The thickness of the baffle material reduces the internal

volume so this must be subtracted from the outside dimensions to

determine the internal volume.The speaker itself also reduces the

internal volume.The amount of air displaced by each model is listed on

the specification sheet and should also be subtracted from the gross

volume calculation.

S

AFETY

C

ARTON

C

ONTENTS

CAUTION:

Before installation, disconnect the battery

negative (-) terminal to prevent damage

to the unit, fire and/or possible injury.

PRACTICE SAFE SOUND™

Continuous exposure to sound pressure levels over 100dB may

cause permanent hearing loss. High powered auto sound systems

may produce sound pressure levels well over 130dB. Use common

sense and practice safe sound.

•

(1) Punch P3 Shallow Series Subwoofer

•

(1) Painted aluminum decorative trim ring

•

(4) Socket head trim ring screws

•

(8) Socket head wood screws

•

(1) Socket head driver bit

R

ECOMMENDED

E

NCLOSURES

V

ENTED VS

S

EALED

60.0

70.0

80.0

90.0

100.0

110.0

120.0

130.0

10.0

20.0

40.0

60.0

80.0

100.0

200.0

1000.0

Frequency, Hz

Sealed Box

Vented Box

Box Volume

Height" x Width" x Depth"

Divided by (cubic feet)

1728