EX Series

by

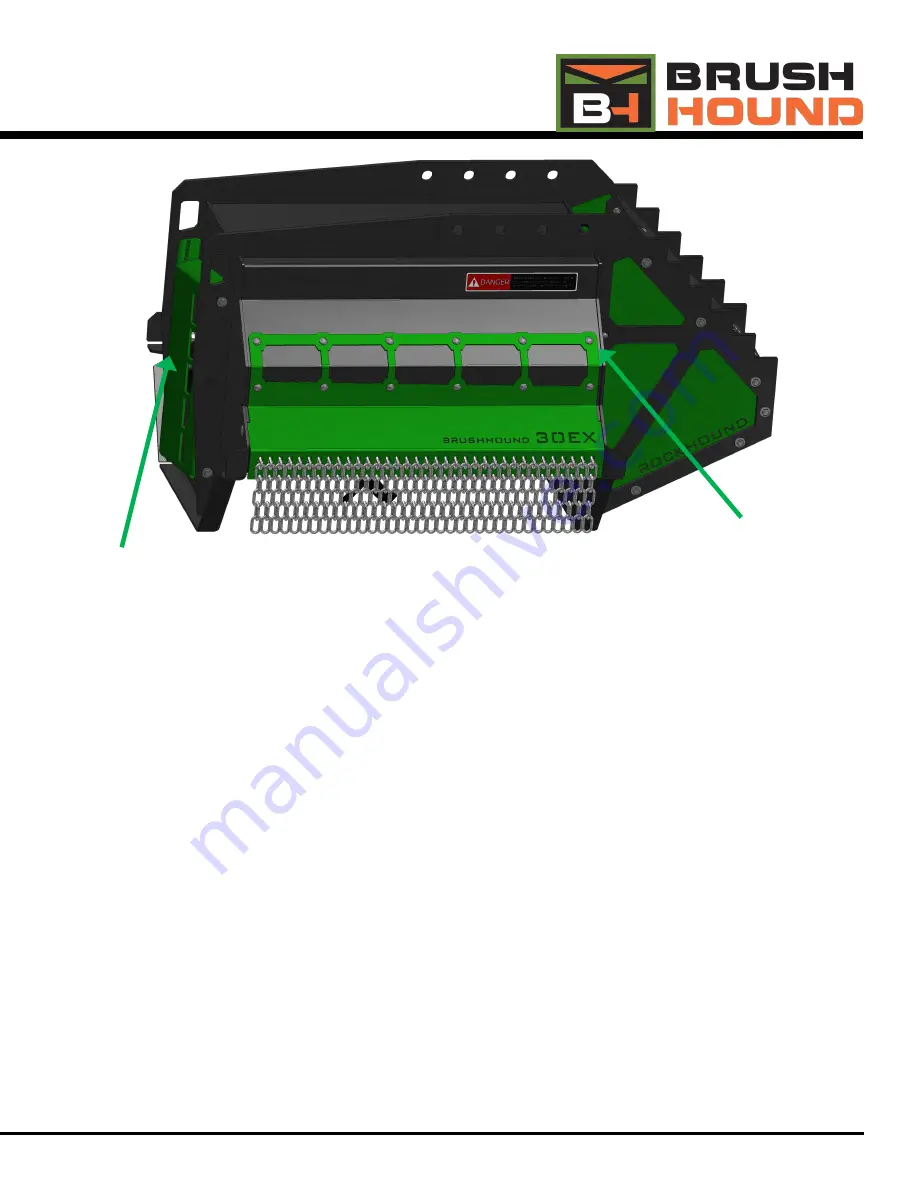

Grease Fitting Locations

b) Hydraulic Hoses

The hydraulic hoses located within the motor guards have been placed to minimize their wear caused by rubbing

against metal surfaces. However, due to heavy vibration their positions can shift so regular inspection for excessive wear

should be performed. The hoses passing through the left motor guard should also be inspected for wear caused by rub-

bing against the bulkhead.

c) Bearings

Bearing failure can be indicated by excessive vibration or noise or the complete seizing of the cutter drum alto-

gether. Imminent bearing failure signs can be more subtle and go unnoticed without appropriate diagnostic equipment.

As a precaution, bearings should be replaced every 1500-2000 hours of operation depending on the environment and us-

age conditions.

d) Safety Guards

Safety guards are in place for the protection of the Operator, bystanders and nearby property and should never

be removed for operation. Therefore, it is important that each safety guard is capable of performing its guarding function.

Any worn guards or guards with rust penetrating deep enough to compromise their strength should be replaced. To pro-

long the guards life, regularly clean the guards and keep them painted as this provides protection from the elements.

e) Safety Decals

Safety decals are not cosmetic, they are in place to warn the Operator and bystanders of the dangers inherent of

this machine. Safety decals should always be clearly legible, even from a distance, and should never be covered for any

reason. Faded or worn decals should be replaced.

Summary of Contents for BrushHound 30EX

Page 2: ......

Page 4: ......

Page 13: ...8 House Rotation Shredding EX Series by Top Down Shredding...

Page 23: ...18 EX Series by Serial Number Plate...

Page 24: ...EX Series Brush Shredder Parts Catalog 19 www rockhound com...