3-2

Program Keypad Module

Key Functions

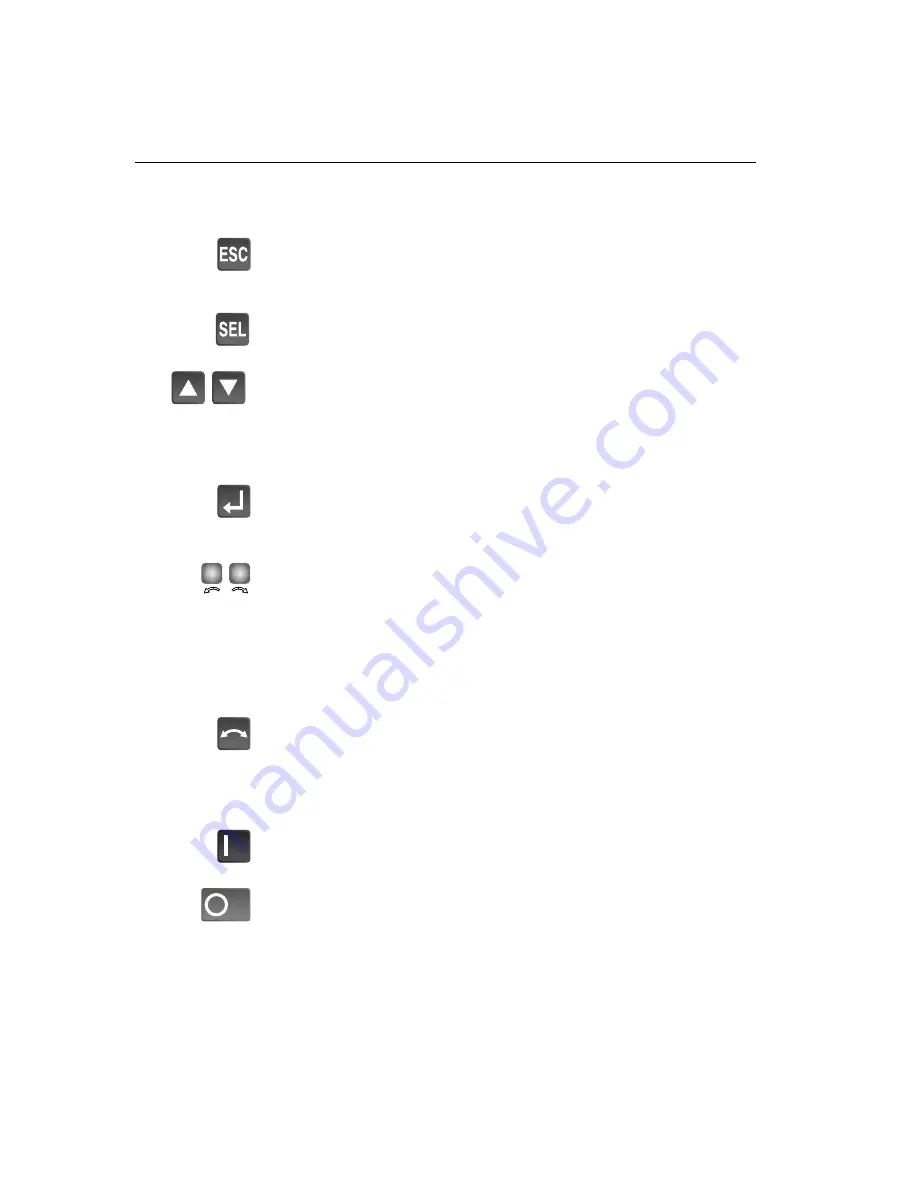

Escape

The ESCape key allows you to toggle between the Display and Program modes.

When the Program mode is active, this key will disable the editing of a parameter

value.

Select

The SELect key enables editing of a parameter value when the Program mode is

active. When you press this key, the Program Mode Indicator flashes.

Up/Down Arrow Keys

Use the Up/Down Arrow keys to scroll through a list of parameters, or

increase and decrease parameter values. Press and hold either key to increase

scrolling speed. Real time frequency adjustment can be achieved when using

P58 - [Internal Frequency]

and

P59 - [Frequency Select]

. Refer to Chapter 5 for further

information.

Enter

Pressing this key causes the current value displayed to be entered into memory

(only while in the Program mode). When you press this key, the Program Mode

Indicator remains on, but stops flashing.

Direction LEDs (Indicators)

The appropriate LED will illuminate continuously to indicate the commanded

direction of rotation. If the second LED is flashing, the drive has been commanded

to change direction, but is still decelerating.

Important:

Actual motor rotation could be different if motor leads are not

connected properly. Refer to Chapter 4 for details on how to verify

correct motor rotation.

Reverse (Change Direction)

This function is only active when

P46 - [Input Mode]

is set to 2. When active, pressing

this key causes the motor to ramp down to 0 Hz and then ramp up to its set speed

in the opposite direction. When the motor is running, pressing this key causes the

(currently illuminated) LED to flash, indicating motor rotation while decelerating

to zero. The other LED will illuminate indicating the commanded direction.

Start

This function is only active when

P46 - [Input Mode]

is set to 2. When active, pressing

this key initiates a start command.

Stop

Pressing the Stop key will cause the motor to stop, using the selected stop mode.

Refer to the

P34 - [Stop Mode]

parameter. If the drive has stopped due to a fault,

pressing this key will clear the fault.

Important:

The Stop key is always active in all control modes.

Summary of Contents for Allen-Bradley 160 SSC Series

Page 12: ...1 6 Getting Started End of Chapter ...

Page 58: ...5 20 Parameters and Programming End of Chapter ...

Page 66: ...A 4 Specifications End of Chapter ...

Page 75: ...Accessories and Dimensions B 9 Drilling Template A Figure B 10 ...

Page 76: ...B 10 Accessories and Dimensions Drilling Template B Figure B 11 ...

Page 82: ...C 6 CE Conformity End of Chapter ...

Page 87: ......