Publication 900-UM007D-EN-E - January 2011

4-50

Parameter Adjustments & Application Considerations

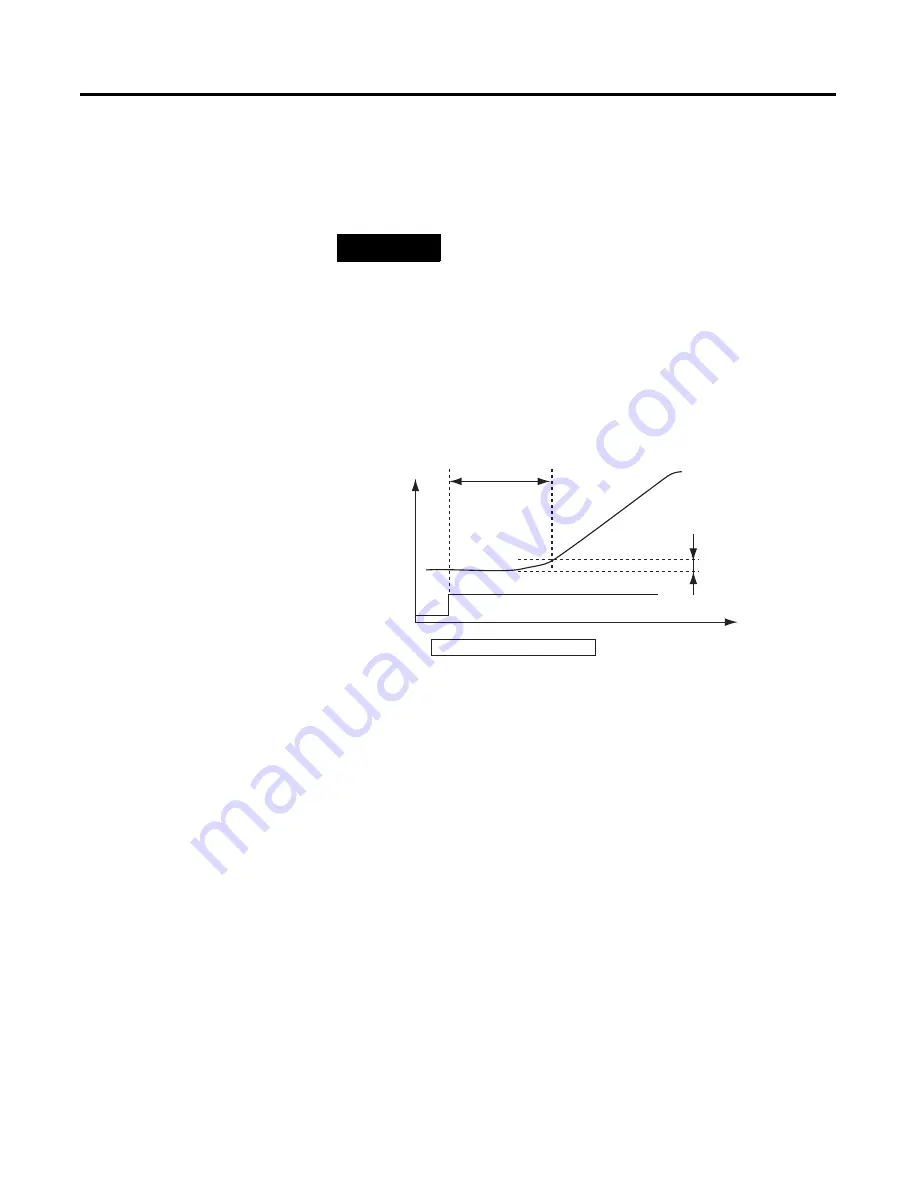

Determining the LBA Detection Time

To manually configure the LBA detection time, configured the LBA Detection

Time parameter to twice the LBA reference time given in the example below.

EXAMPLE

Procedure

1.

Set the output to the maximum value.

2.

Measure the time required for the change in the input to reach the LBA

band.

Figure 4.95

3.

Set the LBA Detection Time parameter to two times the measured time.

LBA Level

Configure the control deviation when the control loop is working properly.

The default is 8.0 (

°

C/

°

F) for Controllers with Thermocouple/Resistance

Thermometer Multi-Inputs and 10.00% FS for Controllers with Analog

Inputs.

LBA Band

There is assumed to be an error in the control loop if the control deviation is

greater than the threshold configured for the LBA Level parameter and if the

control deviation does not change by at least the value configured for the LBA

Band parameter.

The default is 3.0 (

°

C/

°

F) for Controllers with Thermocouple/Resistance

Thermometer Multi-Inputs and 0.20% FS for Controllers with Analog Inputs.

MV = 100%

PV

Temperature

Time

Measurement time

Tm

LBA band

LBA detection time = Tm

×

2

Summary of Contents for Allen-Bradley 900-TC16

Page 1: ...USER MANUAL Bulletin 900 TC8 900 TC16 900 TC32 Series B Temperature Controllers...

Page 2: ...2...

Page 72: ...Publication 900 UM007D EN E January 2011 3 2 Configuration Basic Operation Figure 3 3 900 TC32...

Page 136: ...Publication 900 UM007D EN E January 2011 3 66 Configuration Basic Operation Notes...

Page 340: ...Publication 900 UM007D EN E January 2011 5 112 Parameter Functions Definitions Notes...

Page 350: ...Publication 900 UM007D EN E January 2011 6 10 Troubleshooting Error Indication Notes...

Page 406: ...Publication 900 UM007D EN E January 2011 D 8 Glossary Notes...