18

MP-Series Food Grade Servo Motor Installation Instructions

Publication MP-IN004D-EN-P — April 2009

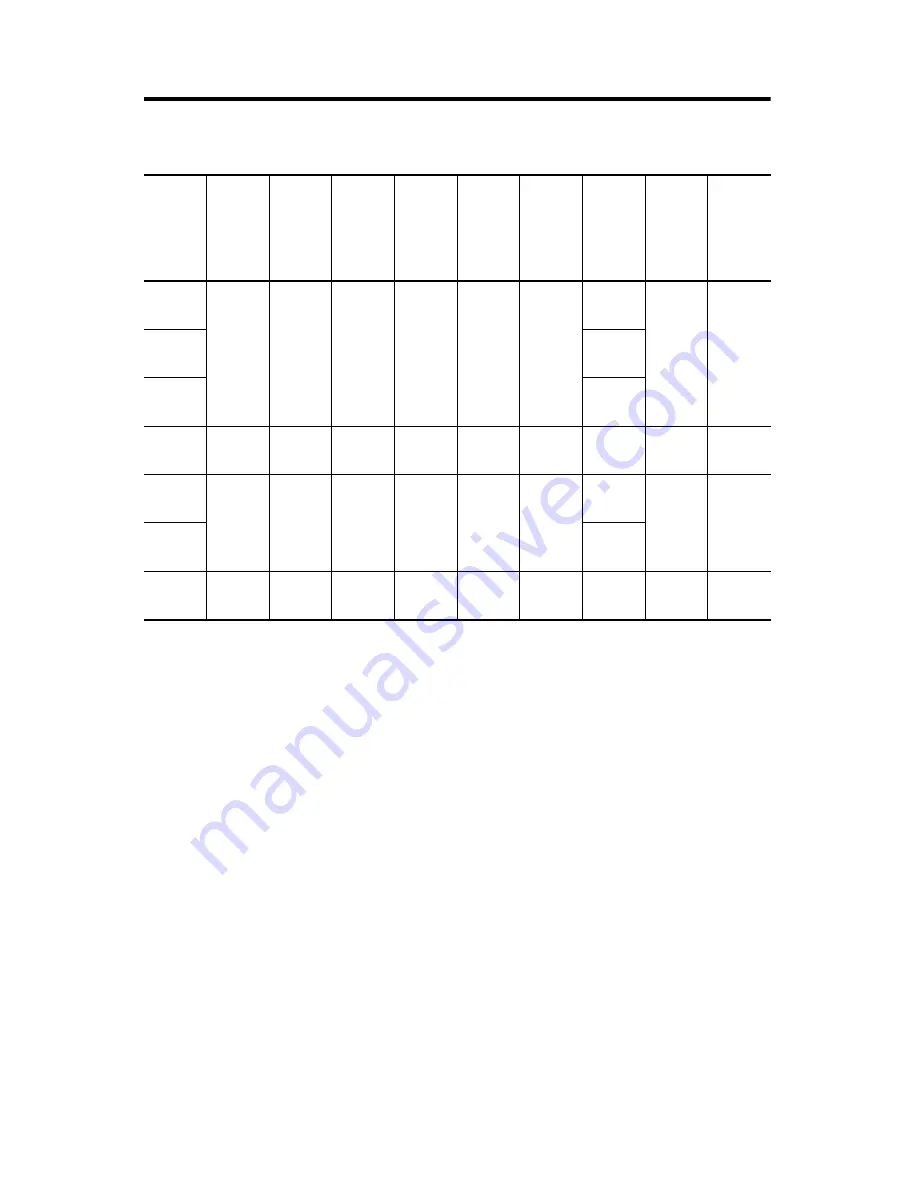

MP-Series Food Grade motors are designed to metric dimensions. Inch dimensions are mathematical conversions.

Motor

Series

MPF-A

or

MPF-B

AB

mm

(in.)

AD

mm

(in.)

D

(2)

mm

(in.)

(2)

Tolerance for this dimension is: MPF-

x

3

xx

+0.008, -0.003 mm (+0.0011, -0.0008 in.); MPF-

x

4

xx

and MPF-

x

45

xx

+0.009,

-0.004 mm (+0.0003, -0.0002 in.); MPF-

x

540 +0.009, -0.004 mm (+0.0003, -0.0002 in.).

F

(3)

mm

(in.)

(3)

Tolerance for this dimension is MPF-

x

3

xx

and -

x

4

xx

-0.03 mm (-0.001 in.); MPF-

x

45

xx

-0.04 mm (-0.001 in.); MPF-

x

540

-0.036 mm (-0.0015 in.).

GE

(4)

mm

(in.)

(4)

Tolerance for this dimension is: MPF-

x

3

xx

and MPF-

x

4

xx

+0.1 mm (+0.004 in.) MPF-

x

45

xx

and MPF-

x

540 +0.2 mm

(+0.007 in.).

HD

mm

(in.)

L

(5), (6)

mm

(in.)

(5)

If ordering an MPF-

xxxx

motor with a brake add: 34.5 mm (1.36 in.) to MPF-

x

310, MPF-

x

320, or MPF-

x

330 dimensions L, LB,

LD. and LE;

48.5 mm (1.91 in.) to MPF-

x

430 dimensions L, LB, LD. and LE; 48.5 mm (1.91 in.) to MPF-x4530 or MPF-

x

4540 dimensions L,

LB, LD, and 48.6 mm (1.91 in.) to LE; and 51.6 mm (2.03 in.) to MPF-

x

540 dimensions L, LB, LD, and LE.

(6)

Tolerance for this dimension is ±0.7 mm (±.028 in.).

L-LB

(6)

mm

(in.)

LA

mm

(in.)

310 67.5

(2.66)

87.25

(3.43)

16.0

(0.629)

5.0

(0.197)

3.0

(0.118)

133.4

(5.25)

168.0

(6.62)

40.0

(1.57)

9.91

(0.39)

320 193.0

(7.62)

330 219.0

(8.62)

430 69.1

(2.72)

90.9

(3.58)

19.0

(0.748)

6.0

(0.236)

3.5

(0.138)

142.8

(5.59)

215.0

(8.48)

40.0

(1.57)

10.16

(0.4)

4530 69.1

(2.72)

98.6

(3.88)

24.0

(0.945)

8.0

(0.315)

4.0

(0.158)

157.6

(6.20)

229.0

(9.0)

50.0

(1.97)

12.19

(0.48)

4540 254.0

(10.0)

540 72.6

(2.86)

136.4

(1)

(5.37)

(1)

This measurement is to the top of the M40 power connector. The measurement to the top of the M23 feedback connector is

83.6 mm (4.47 in.).

28.0

(1.102)

8.0

(0.315)

4.0

(0.158)

209.0

(8.23)

226.0

(9.28)

60.0

(2.36)

13.97

(0.55)