5

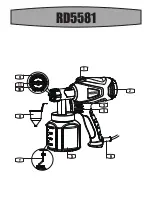

PAINT SPRAY GUN

EN

COMPONENT LIST

ACCESSORIES

Viscosity cup

1

Nozzle cleaning needle

1

We recommend that you purchase your accessories

listed in the above list from the same store that sold

you the tool. Refer to the accessory packaging for

further details. Store personnel can assist you and

offer advice.

PRODUCT SAFETY

GENERAL POWER TOOL SAFETY

WARNINGS

WARNING:

Read all safety warnings,

instructions, illustrations and specifications

provided with this power tool.

Failure to follow all

instructions listed below may result in electric shock,

fire and/or serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or battery-

operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause

you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools.

Unmodified plugs and matching outlets will

1

On / Off switch

2

Motor housing

3

Trigger switch

4

Flow rate adjusting knob

5

Tank

6

Power cable

7

Suction pipe

8

Viscosity cup

9

Cap nut

10

Air cap

11

Nozzle

Not all the accessories illustrated or described are included in standard delivery.

Summary of Contents for RD5581

Page 1: ...RD5581 350W PAINT SPRAY GUN EN ...

Page 2: ......

Page 3: ...RD5581 5 6 1 2 11 10 9 8 7 3 4 ...

Page 4: ...RD5581 5 15cm 25 400 11 10 C D E F G1 G2 H1 H3 H2 B1 B2 A ...

Page 11: ......