24

E10037-180424

PROBEX

4.3

MEMBRANE BURST

In sound rock, a test will be typically stopped when reaching 30 MPa, which normally

occurs before reaching 350 cm

3

if the borehole is tight and uniform (uniform material &

high recovery rate). However, risk of bursting a membrane during a test is unfortunately

always present. This risk depends mainly on the type of rock tested and the experience of

the operator. The following guidelines should help reducing this risk.

Make a borehole with a diameter as tight as possible in order for the membrane to

make contact with the rock as soon as possible i.e. 3 inches or less.

Avoid zones with recovery rates under 90%. When positioning the probe in the

borehole, a special attention must be paid at the core samples in order to avoid clay

seam or weak zone where the probe could bulge locally and burst. Measure accurately

the length of rods used to lower the probe for knowing exactly

the probe’s position

during a test. In zones with low recovery rate, never inject more than 150 cm

3

over 3

inches* and never exceed15 MPa.

When risk of bursting is high, when the borehole is very large, or when the tested

material is very soft, the operator should reduce the pressure increments (to 2, 1, or

0.5 MPa for instance) in order to obtain maximum information out of the test.

Stop the test earlier in case of unusual rock response.

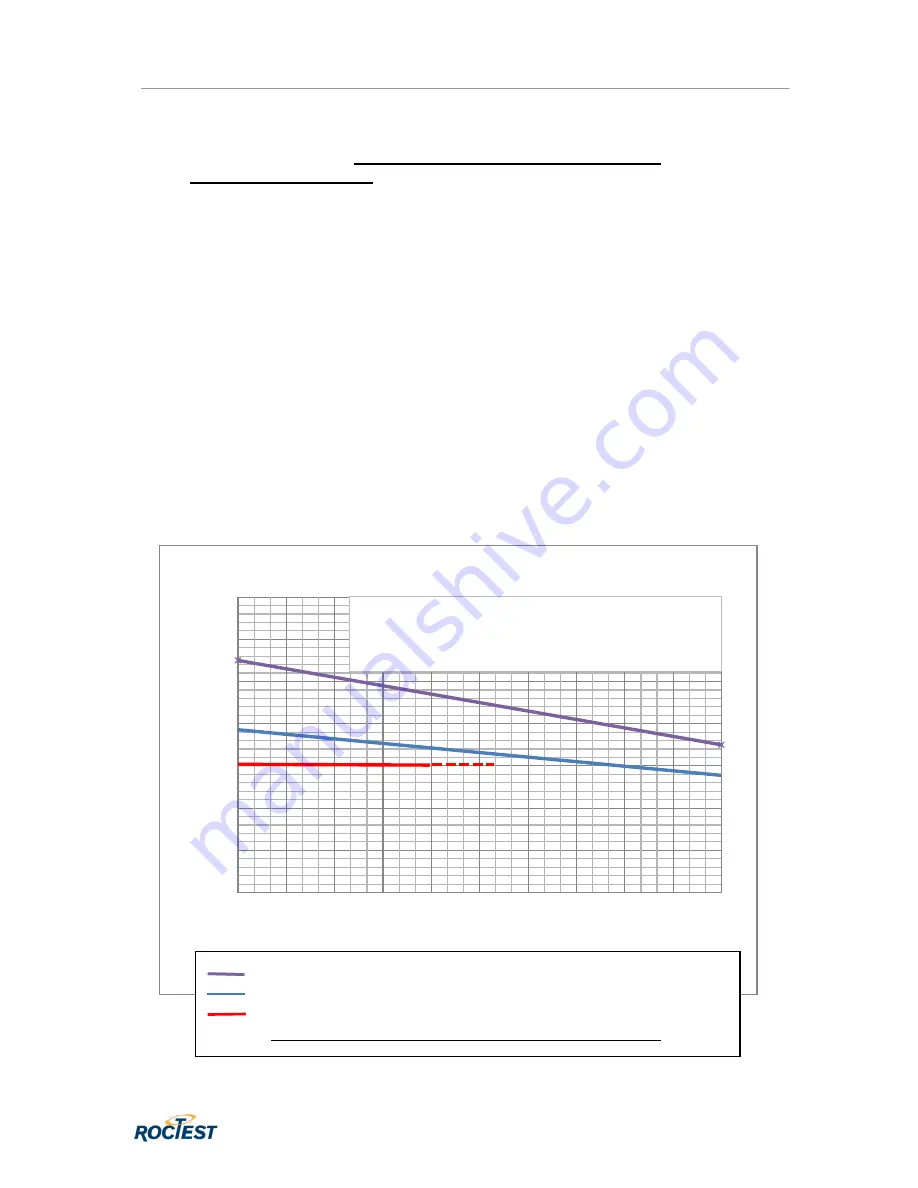

The following chart can be followed:

0

100

200

300

400

500

600

700

0

3000

6000

9000 12000 15000 18000 21000 24000 27000 30000

Vo

lu

m

e

in

c

u

b

ic

c

e

n

tim

e

te

r

(c

m

3

)

Pressure kPa

PROBEX - Maximum Pressure - Volume Values

A Probe in large borehole (contact below 400 cc) & uniform borehole

Unless otherwise specified, the test is terminated typically when reaching 30 MPa

in sound rock, when sufficient data has been accumulated for the intended

purposed of the test, or before reaching high risks of bursting the probe as

indicated on this chart. Note that the probe may burst at lower pressures

depending, among others, on the uniformity of the borehole walls. (V.180405).

Test in a tight (3 in.* or less) & uniform borehole (uniform material & very high recovery rate)

Test in a large (over 3 in.*) & uniform borehole (uniform material & very high recovery rate)

Test in a non-uniform borehole (non-uniform material & low recovery rate)

*Indicated by the volume value obtained at 3 MPa during the volume loss calibration