3. INTENDED AND FORBIDDEN USES

3.1

Intended uses

3.1.1

Extrusion of sealants (silicone, mastic, glues, etc.) contained in dedicated aluminium, plastic or soft-packs cartridges.

3.1.2

Work environments shall be suitable for the products employed, and therefore comply with the product data sheet and safety data sheet.

3.1.3

Use the gun safely, studying all recommendations and implementing all the measures required by this manual.

3.2

Forbidden uses

3.2.1

Extrusion of any specific product, other than those mentioned in the “Intended Uses” section.

3.2.2

Any use other than the extrusion of the aforementioned dedicated products.

3.2.3

Do not use in potentially explosive atmospheres. Do not use products generating potentially explosive atmospheres

3.2.4

Using bulk materials

3.2.5

Using the device without tightening the front ring nut properly

3.2.6

Never cover exhaust air outlets

3.2.7

Never use in environments where dusts or other volatile materials are present.

3.2.8

Never immerse the gun in solvents or acids.

3.2.9

When cleaning the gun, never use hydrogenated hydrocarbons based solvents and/or detergents (1.1.1 Ethyl trichloride,

methylene chloride, etc.) as they could oxidize the galvanized components thus triggering chemical reactions also of explosive

nature; never use highly acid or basic substances when cleaning.

3.2.10

During usage, especially in the air lever release stage, keeping the gun at a distance of less than 30 cm. from the face may be

harmful, as the exhaust air being released through the outlets (11), may hit your face.

3.2.11

Never turn the gun towards oneself, other people, animals or objects, other than the object undergoing treatment.

4. START-UP

to be carried out by the operator

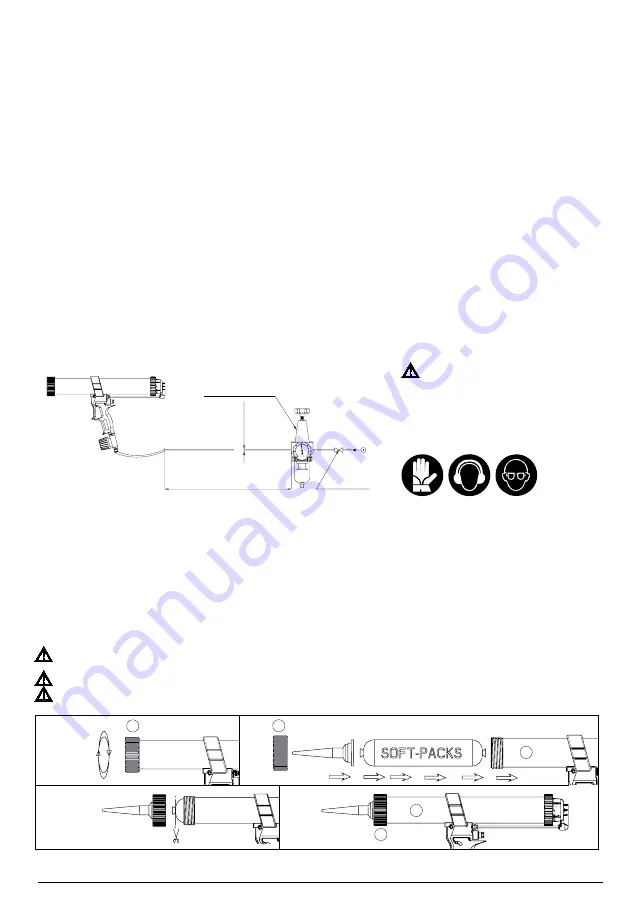

4.1 Air feeding system

Connect the gun to a compressed air system featuring the following characteristics:

• Max. air humidity 5%; • Air temperature from -10° C to +70° C • System capacity 500 l/min at least • System equipped with lubri-

cator; lubrication: 3-4 drops of lubricant every 1000 l/min.

The gun is equipped with a ¼ gas male threaded connector, to which connection is possible according to specific needs. The tube

shall be a wound conductive tube for dynamic laying. Air consumption is reduced and proportional to the number of times in

which the product supply lever is released.

Filter regulator

Ø 6 mm

Fast tap

Max. tube length: 10 m.

Operating pressure: 4-8 bar

Before gun start-up and usage, wear the recom-

mended individual safety devices:

• Safety gloves

• Ear defenders

• Safety glasses

English

8

4.2 Bag refill (Mod RC118N - RC120N - RC119*)

to be carried out by the operator

(*) These models are equipped with a bag conversion kit.

Always disconnect the gun from air feed during bag/cartridge replacement operations and any other time the front ring nut is

unscrewed from the tube. Accidental pressure on the lever may cause the violent unload of the bag and therefore harm the operator or

other people.

Always control the refill material expiry date.

Never introduce damaged or not fully intact bags or cartridges in the gun.

4.2.1

4.2.2

4.2.3

4.2.4

2

2

2

7

7