File No. E183233

RODIX INCORPORATED

TOLL FREE (800) 562-1868, FAX (815) 316-4701

E-mail custserve@rodix.com

rodix.com

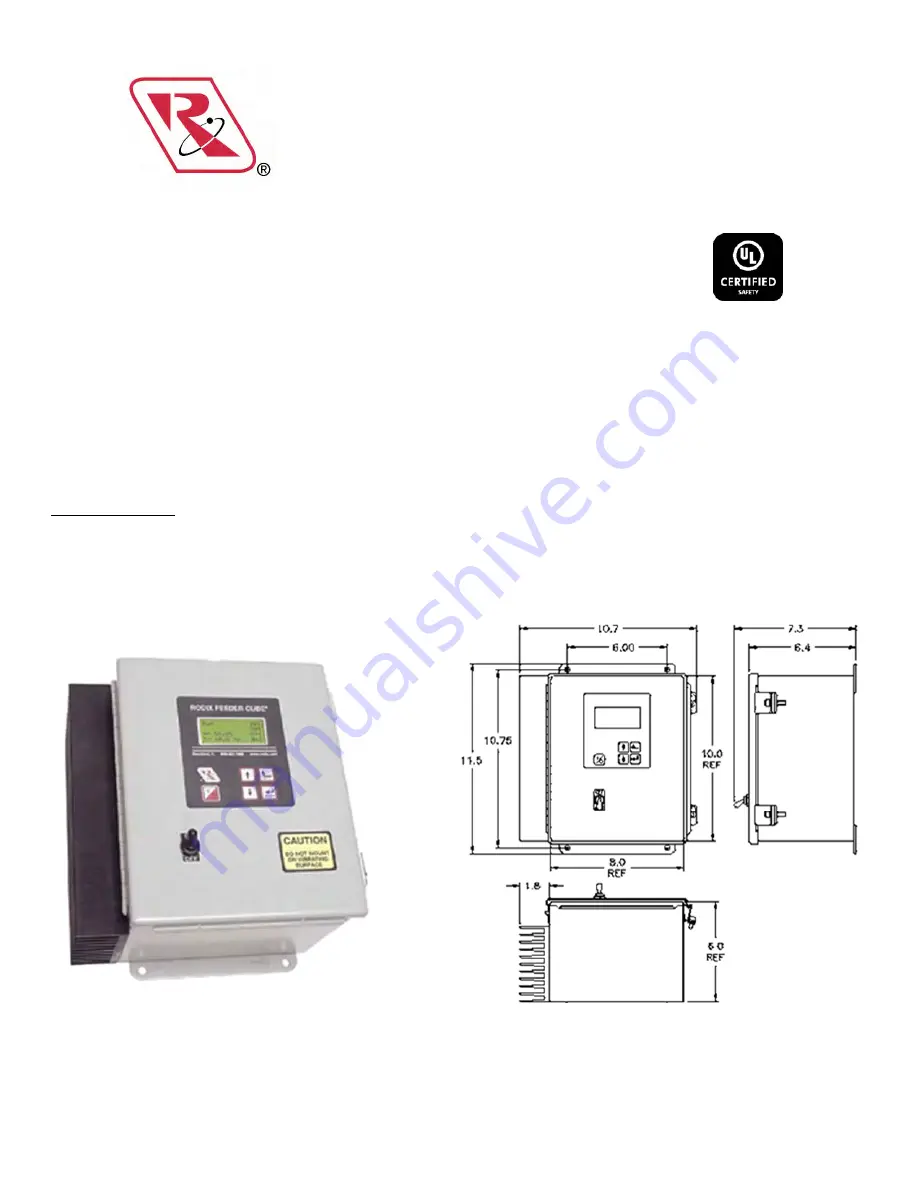

FEEDER CUBE ®

VF-9-OR, P/N 121-000-0752* and 121-200-0752

* Includes CFR vibration sensor P/N 123-215

OIL RESISTANT MODEL

IMPORTANT: APPLICATION NOTE

Input: 85 - 264 VAC, 50/60 HZ.

Single Unit Fuse Size: 5 AMPS

Output: 0 - 120/240 VAC

Maximum output voltage matches input voltage

Output Frequency: 5 - 180Hz

Rated Output Current: 9 Amps at 120V or 7 Amps at 240V

Rated for IP54 environment

UL rated for Type 5 environment

Model Information: The Autotune Series of Variable Frequency Feeder Cubes® generates an output frequency for feeding

that is independent from the power line frequency. An optional vibration sensor, P/N 123-215, can be used to maintain the

vibratory feeder at a constant feed rate. The start/stop operation of the output can be controlled with an optional parts

sensor. For more information on this control, refer to the enclosed Adjustments and Set Up pages.

© 2005, 2020 RODIX

INC

.

VF-9-OR H.docx 11/20/20 Page 1