Model - FC-70-240

Plus

P/N 121-000-1108

Circuit Board P/N 24-215

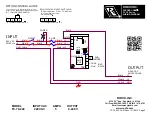

Input:

240 VAC, 50/60 HZ.

(Operating range 190-250 VAC)

Single Unit Fuse Size: 5 AMPS

Output: 0-240 VAC

© 2015 RODIX

INC

.

Warning: To avoid shock, remove power

before making any changes to the circuit

board settings or connections. The

control is not isolated from the power

line.

1. SELECT THE PULSE SETTING

Match the control’s pulse mode to the feeder’s tuning:

A. For 60 pulse output - Set DIP switch (S1, position

1) to 60 on the circuit card.

B. For 120 pulse output - Set DIP switch (S1,

position 1) to 120 on the circuit card.

C. For 60 Reverse pulse setting see the “Feature

Programming Chart”. The “60 Pulse Reverse”

feature is useful for reducing mechanical vibration

interaction between different feeder components

mounted on the same machine table. To

determine if there is a feeder interaction, remove

the power from one feeder. If a feeder interaction

exists, the feed rate on the other feeder will either

speed up or slow down.

D. For 40 pulse output see the “Feature

Programming Chart”. The 40 Pulse rate can be

useful in a minority of applications for feeding

heavy parts. The power output is not as high as

60 pulse mode. A vibratory feeder that is

converted to a lower pulse mode will require

fewer springs.

2. AMPLITUDE POT

The output power is controlled by the

AMPLITUDE

POT

. It is a logarithmic-tapered power out curve

(non-linear) that spreads the power broadly across the

AMPLITUDE POT

. The logarithmic taper power curve

helps to give maximum "Fine Control" over the output

speed of the vibratory feeder.

3. SETTING THE SOFT-START

The start-up rate of the control’s output can be set to

ramp up to the desired output level instead of starting

abruptly. The Soft-start keeps parts from falling off

the tooling, reduces spring shock, and hammering

when the control turns ON. Set position 2 of S1

DIP switch to the ON position to enable the two

second

SOFT

Start function. Set position 2 of S1

DIP switch to the OFF position to disable the

SOFT

Start function.

4. REMOTE OFF/ON CONTROL

A Run Jumper has been installed at the factory as

shown on the enclosed wiring diagram.

Remote OFF/ON operation of the FC-70 Series

Feeder Cube

®

control can be configured to operate

in one of the following ways.

A. A

low current switch

such as a paddle switch

can replace the factory-installed Run Jumper

"J1." The "Run Contact" connects to terminals

TB2-3 and 4. The contact must be isolated

and be able to switch 24VDC and 2mA. The

control will run when the contact is closed.

Refer to Section A of the OFF/ON CONTROL

GUIDE.

B. Low Voltage DC can be used to turn the

control ON and OFF. Remove jumper "J1"

from TB2 terminals 3 and 4. Then connect the

positive signal (+12 to 24VDC @ 5mA) to TB2

terminal 2 and the negative to terminal 1 of

TB2. The control will now turn ON when the

DC signal is present at terminals 1 and 2 of

TB2. This input is optically isolated. Refer to

Section B of the OFF/ON CONTROL GUIDE.

There is a “RUN” status LED that lights up when

either the low current switch is closed or when an

external low voltage DC signal is applied. The

control’s output will be ON whenever the “RUN”

LED is lit and the AMPLITUDE POT is turned up.

5. LINE VOLTAGE COMPENSATION

Fluctuations in the line voltage can cause a feeder

bowl to vary its feed rate. The line voltage

compensation feature adjusts the control's output

to help compensate for fluctuations in the supply

voltage. If it becomes necessary to disable this

feature, remove resistor “R20” from the circuit

board. R20 is located near the Triac labeled Q1.

With the input power disconnected, a knife can be

used to cut down through “R20”.

FC-70-240 24-215.doc 12/23/2015 Page 1

ADJUSTMENTS

AND SET UP

RODIX INC.

FEEDER CUBE

FC-90

Plus Series

GENERAL PURPOSE

RODIX INC.

FEEDER CUBE

FC-70 SERIES

General Purpose