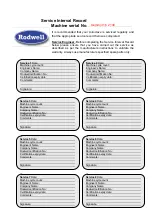

Daily Maintenance by Operator

1) E

nsure that all safety interlocks are operating correctly. In the event of failure

DO NOT

use the autoclave. Call a person in authority.

2)

Check that the Load temperature probe is not damaged or defective before each cycle.

(If the probe is damaged the autoclave must

NOT

be used, Call a person in authority).

3)

Check the door seal to ensure that it is in a good condition free from any cuts or

abrasions, clean with a damp cloth.

4)

Clean all foreign matter from the chamber. The surface of the chamber should be

washed with water containing a mild detergent; the baskets should be cleaned in a

similar way. (Materials that will leave deposits such as cotton wool should not be used

for cleaning)

5)

Keep the autoclave clean and free from dust and dirt.

Weekly Maintenance

1)

Check the calibration of the temperature and pressure gauges together with the chart

recorder if fitted. (120.5ºC = 1.0bar, 134 ºC = 2.0bar)

2)

Check that indicating display and alarms function correctly.

3)

Check pipe connections for signs of leaks.

4)

Lightly lubricate the door bolt with high melting point copper slip.

5)

Back up all logs on the USB memory stick

Monthly Maintenance

1)

Check that the daily and weekly maintenance has been carried out.

2)

Scrub out chamber and remove any deposits. Ensure that materials used do not have

any ferrous content (Steel wool etc. will leave a contaminated deposit and the chamber

will appear to have rusted).

3)

Check door bolt and hinges for wear.

This autoclave is fitted with several safety interlocks which will require periodic maintenance

and adjustment. In the interest of safety and to help to prolong the life of the autoclave,

regular maintenance must be carried out by a competent engineer at least every

6 months

or

300 cycles

if sooner in order to ensure that the equipment is in safe operating condition and

that it maintains a satisfactory level of performance. It should also become standard practice

to carry out the routine checks as listed above.