Common drain, blown-down and transfer lines

24 Independent drain lines and blow-down lines should be

provided. If this is not practicable, devices should be provided

to ensure that only one autoclave blow-down valve can be in

the open position at any one time, in order to safeguard

against inadvertent pressurisation or scalding. Where the

exhaust steam from one autoclave is re-used in another

autoclave, it is essential to provide a valve in the transfer line,

which is interlocked with the door locking mechanism of the

autoclave to which the steam is being supplied.

25 No person should be permitted to enter the confined

space of an autoclave unless an assessment has been made

of the risks to health and safety. This is particularly important

when fumes or an inert atmosphere such as nitrogen may be

present. Following the assessment a safe system of work

should be drawn up and implemented. Persons entering an

autoclave should use a key or tag to prevent the door being

closed behind them.

Autoclaves for sterilizing liquids in sealed glass

containers

26

To reduce the possibility of sealed glass containers

exploding when an autoclave sterilizer door is opened, a

temperature sensing device should be provided which

controls a door interlock arranged to prevent the door opening

until the temperature in all the containers has fallen to less

than 80

0

C

.

The sensing device may be inserted into a

simulator, designed so that its temperature on cooling is

never less than that of any part of the load. Where it is not

reasonably practicable to provide a temperature sensitive

interlock, a time activated interlock may be used set to ensure

an adequate cooling period. Whatever method is used, the

controls should be tamper-proof and should only be set or

adjusted by authorised persons.

INTERLOCKING

27

In the context of autoclave safety, any interlock should

ensure that the door cannot be opened when potentially

dangerous conditions exist within the autoclave and that a

cycle cannot be initiated until the door is completely closed,

the securing mechanism is fully and correctly engaged and

the chamber sealed.

28 Some of the situations in which interlocks should be

provided have been described in paras 18 to 26.

29

Because an operator relies on the safety afforded by

interlocks it is essential that all interlocks should fail to safety.

It is also essential that the interlock devices are sufficiently

robust and securely attached to the autoclave prevent them

being distorted, overridden, or defeated during normal

operation. They should function reliably, be properly

maintained and be kept correctly adjusted, strictly in

accordance with the manufacturers instructions. This is

particularly important where safety is dependent on limit

switches. If these are out of

Adjustment they could allow premature operation of a

following sequence with dangerous consequences. Useful

guidance on the principles of application of interlocking

devices is given in BS5304:

Safety of machinery.

30

A properly trained and authorised person should

check at regular intervals that the interlocks function correctly

and cannot be easily overridden or defeated; this should be

done at least daily if the autoclave is in constant use.

TRAINING

31

Operators of autoclaves should be fully instructed and

properly trained in correct operating procedures and the

purpose and function of controls and safety devices. They

and their managers should be aware of the dangers of

by-passing or interfering with safety devices or of other

malpractices. Manufacturers' instructions and operating

procedures should be readily available to operators and

should always be adhered to and any malfunction or faulty

equipment should be reported without delay to an appointed

superior who will ensure that appropriate remedial action is

taken.

EXAMINATION AND MAINTENANCE

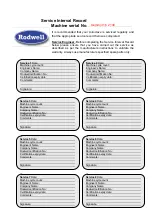

Initial testing and inspection

32

An initial pressure test in accordance with the design

standard should be carried out on each autoclave to

demonstrate its integrity as far as it is possible with a test of

this nature. This test should be carried out in the presence of

a competent person, who may be the representative of an

independent engineering inspection organisation. All

interlocks and safety devices should be assessed and

inspected for correctness of operation before the autoclave is

taken into use. A report of the test and inspection should be

made available to the user and retained by him.

Note:

Pneumatic testing is not recommended, as it is

hazardous and requires special safety precautions.

Advice is contained in Guidance Note GS4 -

Safety in

pressure testing

and in BS 5500.

33

In addition to any information which may be required

by the relevant legislation, the following information should be

permanently marked on the vessel:-

(a)

The name of the manufacturer or his identifying

mark.

(b)

The serial number

(c)

The design pressure

(d)

The design temperature

(e)

The hydraulic test pressure

(f)

The date of hydraulic test

(g)

Date of manufacture and manufacturing standard.