28

EN

28

che

possano

danneggiare

il

cavo

di

alimentazione.

18

MAINTENANCE

N.B.:

Only use original spare parts when repairing or replacing products.

The installer must provide the user with complete instruction for using

the motorised door or gate in automatic, manual and emergency modes,

and must hand the operating instructions to the user of the installation

upon completion.

The installer must compile the maintenance log book, in which all

scheduled and unscheduled maintenance operations performed must

be indicated.

• The installation must be subject to regular maintenance. We

recommend servicing at least once every 6 months.

• Disconnect from mains electricity and from battery power (if

applicable) to avoid the risk of accident or injury.

• Check the tightness of all the fastener screws and nuts.

• Clean the photocell lenses with a cloth moistened slightly with water.

Do not use solvents or other chemical products, as these may damage

the electronic components.

• Clean and lubricate the pivot points with lithium based grease (EP

LITIO).

• Check the electrical connections.

• Check that the manual lock release system works.

• Check that the boom is balanced correctly as indicated in chapter 12.

• Check that there are now plants within the radius of action of the boom

which could interfere with the photocells or with the movements of

the boom itself.

Reconnect to mains power.

• Check that the safety devices and all the control functions work

correctly.

• Check that the obstacle detection function works correctly.

• Check that there is no risk of the boom accidentally lifting persons or

objects.

• Check that the force limiting function prevent potentially dangerous

situations in compliance with the standard EN 12445.

19

DISPOSAL

This product may only be uninstalled by qualified technical

personnel, following suitable procedures for removing the

product correctly and safely.

This product consists of numerous different materials.

Some of these materials may be recycled, while others must

be disposed of correctly at the specific recycling or waste

management facilities indicated by local legislation applicable for this

category of product.

Do not dispose of this product as domestic refuse.

Observe local legislation for differentiated refuse collection, or hand the

product over to the vendor when purchasing an equivalent new product.

Local legislation may envisage severe fines for the incorrect disposal of this

product.

Warning!

some parts of this product may contain substances that are

harmful to the environment or dangerous and which may cause damage

to the environment or health risks if disposed of incorrectly.

20

ADDITIONAL INFORMATION AND CONTACT

ROGER TECHNOLOGY is the exclusive proprietor holder of all rights

regarding this publication.

ROGER TECHNOLOGY reserves the right to implement any modifications

without prior notification. Copying, scanning or any alterations to this

document are prohibited without express prior authorised from by

ROGER TECHNOLOGY.

ROGER TECHNOLOGY CUSTOMER SERVICE:

business hours:

Monday to Friday

08:00 to 12:00 - 13:30 to 17:30

Telephone no:

+39 041 5937023

E-mail:

support@rogertechnology.it

Skype:

service_rogertechnology

FIG. 1

21

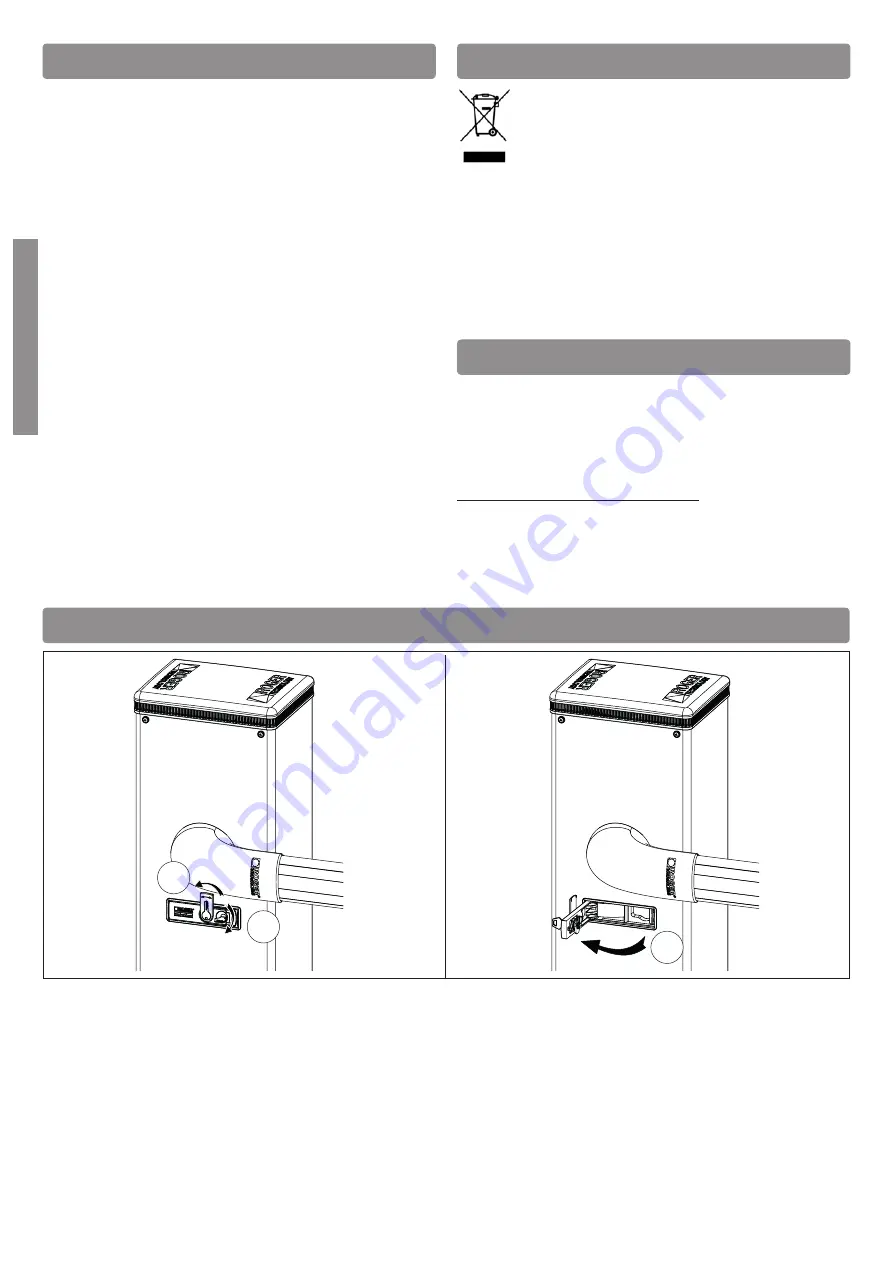

RELEASE AND LOCK PROCEDURE

Unlock the barrier in the event of a power outage or before performing scheduled maintenance or repairs. The unlock procedure must be performed

with the boom in the closed position.

Ensure that there are no persons, objects or animals within the operating radius of the barrier when unlocking.

RELEASE AND MANUAL OPERATION

Open the lock cover as indicated in step 1.

Insert the key included into the lock and turn clockwise by 90°, as indicated in step 2.

Open the release cover completely (

3

).

Move the boom manually.

RESTORING AUTOMATIC OPERATION

To relock the barrier, close the release cover by turning the key 90° clockwise, paying attention to your fingers.

With the door closed, turn the key 90° anticlockwise.

Remove the key and close the lock cover.

FIG. 2

90°

1

2

3

Summary of Contents for BI/004

Page 1: ......